Our vertical dock leveler provides an efficient and precise lifting solution, helping you optimize vertical space in your warehouse and logistics center. Whether handling large cargo or frequent operations, this platform delivers outstanding durability and safety.

Offering [X years] of warranty and lifetime support, safeguarding your investment.

Customizable Solutions for Your Unique Loading Needs

Our vertical dock leveler is designed to adapt to your specific operational requirements. With customizable options in size and load capacity, this platform provides seamless height adjustments and enhances efficiency in any warehouse or industrial setting. Explore how it can optimize your cargo handling and save space.

Vertical Lifting Mechanism Explained: The vertical dock leveler smoothly moves between different heights, ensuring seamless cargo handling and improved efficiency. It is especially suitable for scenarios that require frequent height adjustments.

Customization Options: We offer custom platforms in various sizes, load capacities, and surface finishes to meet the specific needs of different industries.

This platform is ideal for industries such as warehousing, logistics, and manufacturing that require vertical space operations, especially for handling high-frequency and large-volume cargo.

Yes, the platform is designed for convenience, with fewer moving parts and minimal maintenance required, reducing downtime and overall maintenance costs.

Our vertical dock leveler can handle up to [X tons] of cargo, making it suitable for a variety of heavy-duty applications.

Yes, the platform is built with corrosion-resistant materials, allowing it to function efficiently in extreme temperature environments, whether hot or cold.

The vertical dock leveler optimizes vertical space, reducing the use of floor space and providing a more efficient cargo handling experience, making it ideal for space-constrained operations.

Standard models are typically in stock and can be delivered within [X days]. Custom models may take longer depending on specific requirements.

Yes, we offer customizable options in size, load capacity, and surface finish to meet the unique needs of various industries.

The vertical dock leveler is equipped with safety features such as automatic locking systems and anti-slip surfaces to ensure the safety of both operators and cargo during loading and unloading operations.

No Contact with the Outdoors and No Airflow: Are you looking for a platform that does not come into contact with the outdoors, preventing air exchange and ensuring full sealing of the loading dock?

Integrated with Insulated Cold Storage Doors: Do you need a solution that works with insulated cold storage doors to provide complete sealing for loading docks?

High Sealing and Insulation Requirements: Are you seeking a platform specifically designed for environments with high sealing and insulation requirements, such as fresh produce, food distribution, catering, and cold chain logistics?

Protection Against Impact: Do you want to effectively protect dock doors from being damaged by impacts?

Reduced Forklift Bumps: Are you looking for a way to minimize bumps during forklift operations to ensure smoother transitions?

Smoother Docking: Do you need a platform that allows for smoother docking, enhancing the overall efficiency of loading and unloading?

Simple Operation: Are you interested in a platform that is easy to operate, featuring a one-button operation to control the entire lift process?

- The vertical storage of the platform effectively protects the dock door from impact.

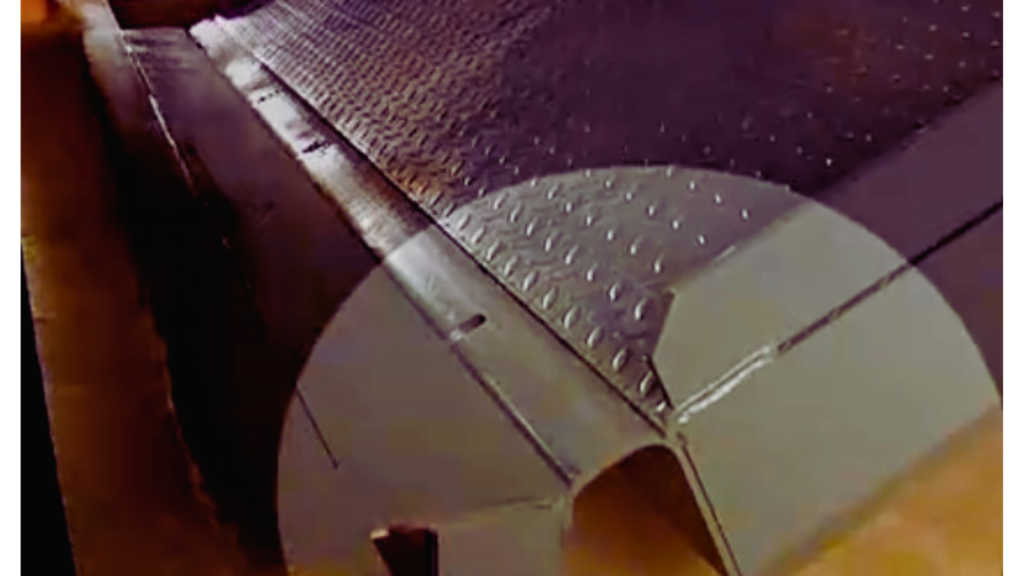

- The ergonomic design of the platform’s tail features a curved transition, reducing bumps during forklift operations.

- The lip plate features a 5-degree duckbill design, ensuring smoother bridging.

- Operation is simple, with a one-button control that allows for the complete raising and lowering of the platform.

A vertical hydraulic dock leveler is an advanced loading and unloading equipment specifically designed for warehouses and logistics centers. It provides superior environmental and safety control, along with smooth transitions for goods between the warehouse floor and flatbed trailers. Here are the main reasons to choose a vertical hydraulic dock leveler:

Excellent Environmental Control

By lowering the sectional door to the pit floor, the vertical hydraulic dock leveler minimizes dust, debris, and rodents from entering the warehouse, ensuring a clean environment. This design also reduces energy loss from the pit-style dock leveler, making it ideal for facilities requiring strict environmental control.Enhanced Safety

The platform can lower the door completely to the pit floor, minimizing gaps in the loading area to enhance safety. Reducing these gaps prevents accidental falls, ensuring a safer operation zone.Smooth Loading and Unloading Process

The design of the platform includes constant radius rear hinges and a two-point crown control device on the front lip extension hinges, providing a smooth transition. These features reduce vibrations for forklift operators, goods, and equipment, ensuring a stable loading and unloading process and minimizing equipment wear.Easy Cleaning and Maintenance

The vertical hydraulic dock leveler is designed for easy routine cleaning or thorough washing, maintaining the hygiene of the platform and surrounding environment. Its easy-to-clean design makes it suitable for industries with high hygiene standards, such as food and pharmaceuticals.Safe Power Control

The platform uses a constant pressure push-button control system, allowing the operator to fully control the platform’s movement. This safe power-up and down control system is safer than traditional systems, reducing operational risks.Flexible Tilt and Float Functions

The vertical hydraulic dock leveler features tilt control, which reduces hydraulic system stress when offset loading. The mechanical balance valve control device located at the bottom of the platform allows the platform to float freely with the changes in truck load, ensuring the stability of goods during loading and unloading.

Choosing a vertical hydraulic dock leveler can improve the efficiency and safety of loading and unloading operations, optimize environmental control, and ease equipment maintenance, making it an ideal solution for modern warehousing and logistics operations.

A vertical standing dock leveler is designed to provide a secure bridge between the loading dock and a truck bed, ensuring smooth and efficient loading and unloading while maintaining environmental and security controls. Here’s a guide on how to properly and safely operate a vertical standing dock leveler.

1. Inspect the Dock Leveler

- Before operating the dock leveler, conduct a thorough inspection to ensure that the platform, hinges, and hydraulic systems are in good condition with no visible damage or excessive wear.

- Check the hydraulic fluid levels and inspect for leaks or damage in the hydraulic lines and cylinders.

- Ensure that all safety mechanisms, such as locking devices and safety legs, are functioning correctly.

2. Prepare the Loading Dock Area

- Clear the loading dock area around the dock leveler of any debris, obstacles, or unnecessary equipment that could impede the operation.

- Make sure the dock door is fully opened, and the area is adequately lit to avoid accidents.

- Position the truck accurately at the dock, aligning it properly with the dock leveler.

3. Operating the Dock Leveler

- Use the control panel to raise the dock leveler into the vertical position.

- With the dock leveler raised vertically, open the truck doors. This position allows the dock door to close tightly against the dock floor, reducing energy loss and enhancing security.

- After opening the truck doors, lower the dock leveler carefully using the control panel. Ensure that the lip of the leveler extends fully and rests securely on the truck bed to create a stable bridge.

4. Conduct Loading and Unloading

- Begin loading or unloading once the dock leveler is in place and secure.

- Use forklifts, pallet jacks, or other material handling equipment to transfer goods between the truck and dock.

- Operate the equipment smoothly to prevent damage or accidents during the transfer of goods.

5. Retract and Store the Dock Leveler

- Once loading or unloading is complete, raise the dock leveler back to the vertical position using the control panel.

- With the dock leveler raised, close the truck doors securely.

- Lower the dock leveler back into its stored position against the dock wall to maintain a secure barrier and prevent energy loss.

6. Close and Secure the Dock Area

- Close the dock door tightly against the vertical dock leveler to maintain a secure seal, preventing entry of dust, pests, and outside air.

- Engage all locks and safety features to ensure the dock area is securely closed.

7. Perform Regular Maintenance

- Regularly maintain the dock leveler by checking the hydraulic system, lubricating moving parts, and inspecting for wear or damage.

- Test all safety devices periodically to ensure they are functioning properly, including emergency stops and safety legs.

- Keep a detailed maintenance log to document all checks, repairs, and maintenance for future reference.

Safety Tips

- Always wear appropriate personal protective equipment (PPE), such as safety gloves, boots, and eye protection, when operating the dock leveler.

- Never exceed the dock leveler’s maximum load capacity to avoid equipment damage or accidents.

- Ensure all operators are properly trained on the dock leveler’s operation and safety procedures.

- If the dock leveler malfunctions or operates abnormally, stop using it immediately and call a qualified technician for repairs.

By following these instructions and safety tips, you can ensure the safe, efficient use of a vertical standing dock leveler, protecting both personnel and goods while maintaining a secure and efficient loading dock environment.

- The vertical dock leveler optimizes the use of vertical space, reducing floor operation congestion and increasing overall warehouse productivity.

- Lower Long-Term Operating Costs: By minimizing manual intervention and reducing operation time, the platform enhances overall loading and unloading efficiency, which in turn reduces labor and time costs.

Success Story 1: Major Logistics Center Increases Efficiency

A well-known logistics company implemented the vertical dock leveler in their warehouse and saw a 30% increase in cargo handling efficiency. The vertical lifting feature allowed them to better utilize warehouse space, reducing the floor space required by traditional dock levelers.

Case 2: Manufacturing Company Reduces Downtime

A global manufacturer utilized a customized vertical dock leveler, reducing operational downtime and improving overall production efficiency. They reported a 25% reduction in downtime due to the platform’s low maintenance requirements.