Get a perfect fit with our customizable sponge dock seals, engineered to handle various truck sizes and dock configurations, all while maintaining peak efficiency and long-lasting performance.

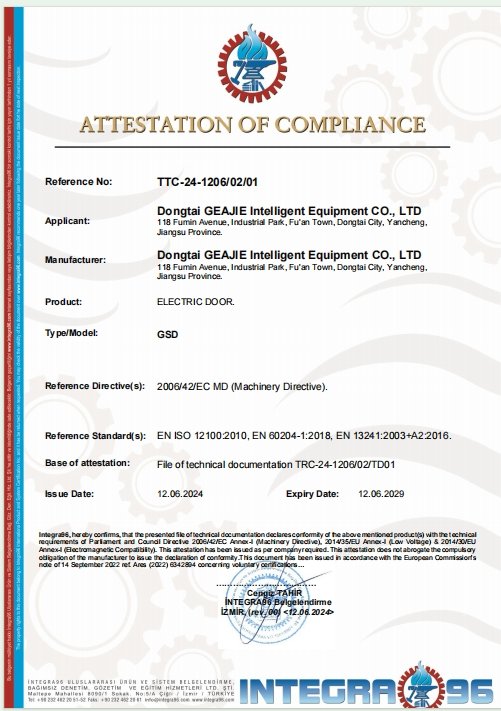

CE Certified: Our stacking doors adhere to European safety and quality regulations, offering you the assurance that they meet rigorous industry standards. Warranty: We provide a [X-year] warranty, ensuring the long-term performance and durability of your doors.

Protect Your Warehouse and Boost Efficiency with Durable, Custom-Fit Sponge Dock Seals

Maximize warehouse protection and operational efficiency with sponge dock seals. These durable, compressible seals provide a tight, custom fit, blocking out external elements while reducing energy loss during loading and unloading. Designed for long-lasting performance, they’re the smart choice for any facility looking to safeguard its goods and cut costs.

How Sponge Dock Seals Work:

Sponge dock seals are designed to create a tight seal between the dock and the truck, using compressible foam to block out external air, moisture, and contaminants. When a vehicle backs into the dock, the foam compresses to form an airtight barrier, preventing temperature fluctuations and enhancing energy efficiency. These seals are ideal for facilities with frequent loading and unloading activities, ensuring smooth operations and product protection.

Customization Options:

Our sponge dock seals are available in a range of sizes, materials, and designs to meet the specific needs of your facility. Whether you require extra-durable materials for high-traffic areas or custom colors to match your branding, we offer tailored solutions. Additional options include adjustable designs for different truck heights and dock configurations, ensuring optimal performance and protection for your warehouse.

Sponge dock seals use high-density foam to create a compression-based seal around trailers, while mechanical dock seals typically involve a more complex system of pads and mechanisms for sealing. Sponge seals are often simpler and cost-effective, ideal for moderate traffic environments.

With proper maintenance and use, sponge dock seals can last for several years, even in high-traffic environments. Regular inspections and cleaning will help prolong their lifespan.

Yes, our sponge dock seals are designed to withstand extreme temperatures, moisture, and UV exposure, making them suitable for a wide range of climates, from cold storage facilities to hot, dry environments.

Yes, sponge dock seals help minimize energy loss by creating an airtight barrier during loading and unloading operations. By preventing external air from entering your facility, they help maintain internal temperatures, reducing the load on HVAC systems and lowering energy costs.

Sponge dock seals are relatively simple to install, with customizable options available to fit different dock configurations. Installation is typically straightforward, but we recommend professional installation to ensure an optimal fit and seal.

Our sponge dock seals are designed to be flexible and compressible, accommodating a wide range of truck sizes. We also offer custom sizing options to ensure a snug fit for any trailer, providing effective sealing across varying vehicle types.

Sponge dock seals require minimal maintenance. Regular cleaning and periodic inspections for wear and tear will help maintain their performance. If any damage is noticed, timely repairs or replacements will ensure continued protection and efficiency.

Yes, we offer a range of customization options for sponge dock seals, including different sizes, materials, and colors to match your facility’s needs. Whether you need enhanced durability for high-traffic areas or specific dimensions to fit unique dock configurations, we can tailor a solution to meet your requirements.

Success Story 1: Improving Temperature Control for a Food Distribution Center

Client: Large-Scale Food Distributor in Japan

Challenge: The client was struggling with temperature fluctuations in their cold storage areas during loading and unloading operations. Their existing dock setup allowed external air to enter, compromising the integrity of their temperature-sensitive products and resulting in increased energy costs to maintain the desired temperature.

Solution: We provided custom sponge dock seals designed specifically for their dock doors. The high-density foam seals compressed tightly against the trailers, creating an airtight barrier that prevented external air from entering the facility. The seals were also coated with a durable, moisture-resistant cover to withstand the frequent loading and unloading cycles.

Results: After installing the sponge dock seals, the client experienced a significant improvement in temperature control, with internal temperatures remaining stable even during peak loading times. This led to a reduction in energy costs by 20%, as well as improved product quality and safety. The client also reported fewer instances of product spoilage, enhancing their overall operational efficiency.

Success Story 2: Enhancing Operational Efficiency for an Electronics Manufacturer

Client: Leading Electronics Manufacturer in South Korea

Challenge: The client faced challenges with dust and debris entering their facility during loading and unloading, which affected the quality of their sensitive electronic components. The lack of a proper seal between the dock and trailers also posed a risk of contamination and increased the need for frequent cleaning and maintenance.

Solution: We recommended and installed sponge dock seals with a reinforced outer fabric to withstand the high traffic at their loading docks. The seals were designed to compress snugly around the trailers, effectively blocking out dust, debris, and external air. We also provided a custom size fit to ensure optimal sealing for their specific dock and trailer configurations.

Results: Following the installation, the client noticed a dramatic reduction in dust and debris entering their facility, leading to improved product quality and a decrease in cleaning costs. The sponge dock seals also helped maintain a stable indoor environment, reducing the need for temperature adjustments. As a result, the client reported a 30% improvement in operational efficiency and a reduction in production downtime.

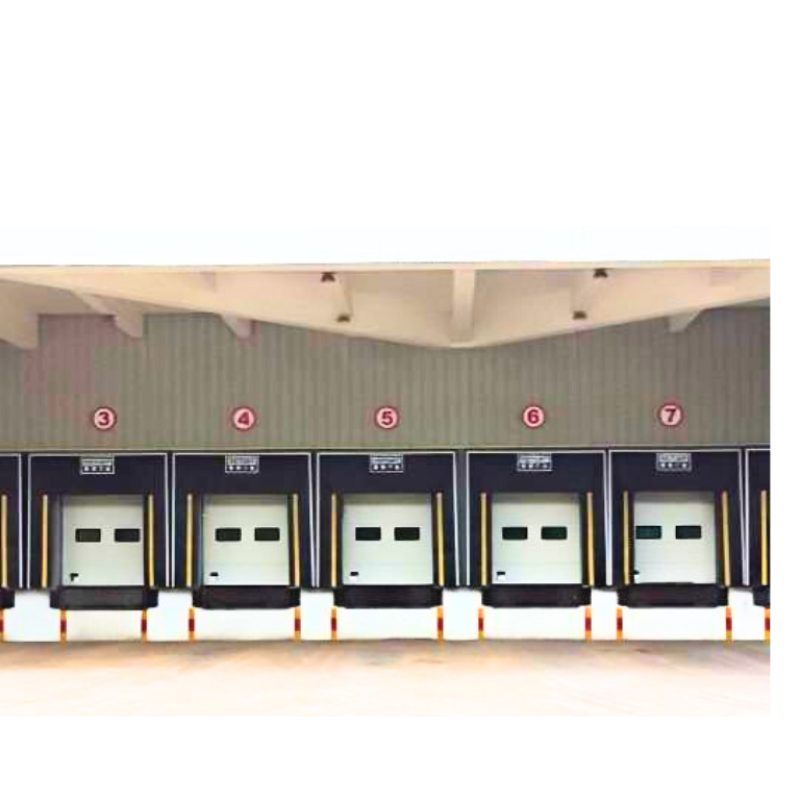

Good Sealing and Cost-Effectiveness: Are you looking for a solution that offers excellent sealing performance while being economical?

High Sealing Requirements for Cold Storage: Do you need a product specifically designed for cold storage environments where high sealing is required?

Suitable for Various Industries with High Sealing Needs: Are you looking for a solution suitable for food, pharmaceutical, supermarket, cold chain, and warehousing industries, where transport vehicles are relatively standardized and high sealing is essential?

- Ideal for situations where transport vehicle sizes are relatively uniform, and the building walls need to withstand certain pressure.

- Made with sponge material that has a compression ratio greater than 70%, it quickly returns to its original shape after compression.

- The unique trapezoidal sponge pressure-relief cross-section design effectively reduces friction between the dock seal and the truck, extending the dock seal's service life.

- The surface of the side dock seals features evenly distributed wear-resistant louvers that provide multiple layers of protection against abrasion, significantly extending the dock seal's lifespan.

- The bottom of the side dock seals is equipped with reflective yellow guide strips to assist truck drivers in reversing operations.

- Additionally, the bottom and back of the side dock seals are designed with metal grommets to ensure even air release, preventing the fabric from bursting due to sudden pressure from the truck.

Sponge dock seals are an efficient sealing solution designed for loading docks, suitable for a variety of warehousing and logistics environments. By sealing the gaps between vehicles and warehouses, sponge dock seals not only protect the internal environment but also improve operational efficiency and reduce energy consumption. Here are the main reasons to choose sponge dock seals:

Excellent Sealing Performance

Sponge dock seals are made of high-density foam material that tightly conforms to the perimeter of trucks or containers, effectively preventing wind, rain, dust, and external hot air from entering the warehouse. This design helps maintain a stable temperature inside cold storage or warehouses, reducing energy consumption and protecting the quality of stored goods.Durability and Structural Reliability

The backing of the dock seal is made from pressure-treated wood coated with weather-resistant paint, enhancing its durability and resistance to the elements. High-density foam is bonded to the wooden backing with elastic industrial adhesive, ensuring that the foam pads remain in the optimal position, extending their lifespan and providing good compression performance.Flexible Design Adaptability

Sponge dock seals can be customized to meet various loading needs and are suitable for different widths and heights of dock doors. The retractable frame design allows it to adapt flexibly to different types of vehicles, offering multiple sealing solutions to meet diverse requirements.Enhanced Protective Features

Sponge dock seals are equipped with vent holes and drainage designs to prevent the buildup of air and moisture, reducing wear and tear and preventing corrosion. The tapered bottom structure helps prevent damage to the seal when trucks dock, enhancing its protective features and durability.Variety of Sizes and Specifications

Sponge dock seals come in various sizes and specifications to accommodate different loading needs. They are suitable for common 8′, 9′, and 10′ wide dock doors and feature high-visibility yellow guide stripes to ensure accurate positioning of trucks during docking.Easy Installation and Maintenance

Sponge dock seals are easy to install with basic tools. The design of flat brackets and angled brackets makes the installation process quick and efficient, reducing maintenance costs and the need for frequent replacements.Improved Working Environment

By providing effective sealing performance, sponge dock seals help improve the working environment in warehouses, preventing external conditions from affecting internal temperature and air quality, enhancing employee productivity and storage conditions for goods.

Choosing sponge dock seals provides excellent sealing and protective performance, extends the life of equipment, reduces energy consumption, and ensures the safety and efficiency of warehouse operations, making them the best choice for enhancing the performance of logistics and warehousing facilities.

A foam dock seal is commonly used in loading areas of warehouses, cold storage facilities, and logistics centers. It provides an effective seal by using soft foam pads that tightly press against the truck, preventing external dust, rain, and cold air from entering. Foam dock seals are ideal for environments that require goods protection and consistent indoor temperatures. Here are the steps and precautions for using a foam dock seal to ensure safe and effective operation.

1. Inspect the Condition of the Dock Seal

- Before use, check the condition of the foam dock seal to ensure the foam pads, frame, and support structures are free from damage or significant wear.

- Assess the foam pads for elasticity and sealing ability, ensuring they can form a tight seal with the truck trailer.

- Confirm that all fasteners and fittings (such as bolts and nuts) are securely installed and not loose.

2. Prepare the Loading Area

- Clear the area around the dock seal, removing any items that could obstruct the operation, such as debris, tools, or equipment.

- Ensure the truck is properly positioned in the designated loading area and use wheel chocks to secure the vehicle, preventing movement during loading or unloading.

3. Align the Truck

- Guide the truck to back up slowly, aligning it with the foam dock seal.

- When the truck is stationary, ensure the perimeter of the trailer is tightly pressed against the foam pads, creating an effective seal to block external air or moisture.

4. Verify the Seal Position

- Confirm the truck is properly docked and the foam pads are in tight contact with the trailer, ensuring a good seal.

- Make sure the foam dock seal does not move or deform during loading and unloading to maintain its sealing performance.

5. Begin Loading and Unloading Operations

- After the truck is securely docked and aligned, open the trailer doors to start loading or unloading goods.

- Ensure goods are safely loaded and unloaded, avoiding any impact or damage to the dock seal.

6. Complete the Loading and Unloading Process

- After loading or unloading, check that all goods are safely loaded or removed, and close the trailer doors.

- Guide the truck to slowly move away from the loading area, ensuring the foam dock seal is not pulled or damaged.

7. Clean and Maintain the Dock Seal

- After use, check the foam dock seal for any wear or damage.

- Regularly clean the foam pads and frame to prevent dust and debris buildup, maintaining effective sealing.

- Inspect all fasteners and moving parts to ensure they are in good working order, and perform necessary maintenance.

Precautions

- When using the dock seal and loading goods, wear appropriate protective gear, such as gloves and safety shoes.

- Avoid parking the truck too quickly to prevent impact damage to the dock seal.

- Ensure all operators are familiar with the correct usage and safety precautions for the foam dock seal.

- If any abnormalities or damage are found, stop using the dock seal immediately and contact a professional for inspection and repair.

Following these steps and precautions when using a foam dock seal can ensure the safety and effectiveness of the equipment, improve loading efficiency, and extend the dock seal’s lifespan.