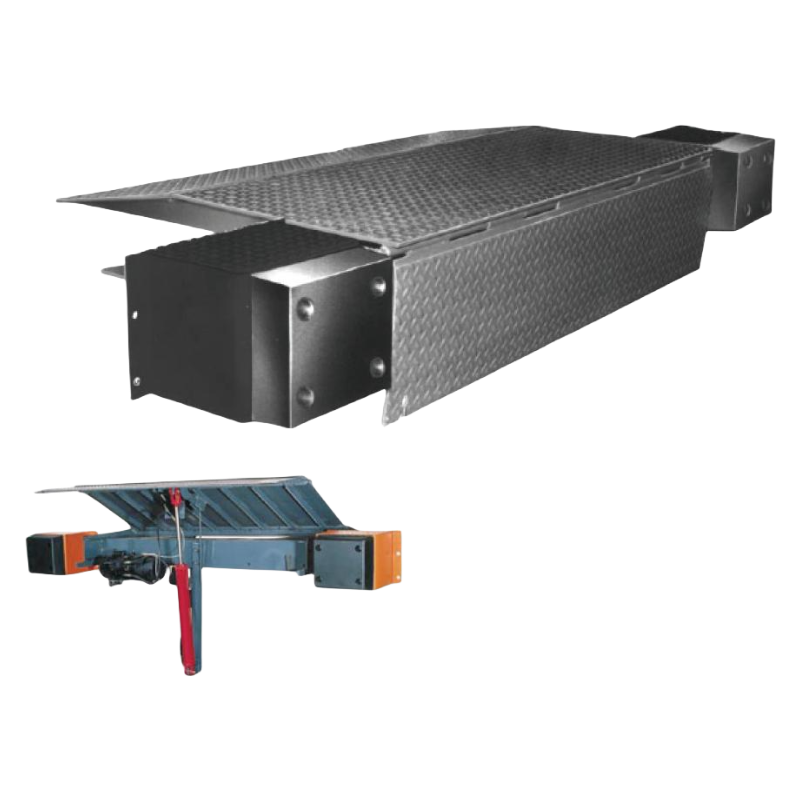

Manual and electric edge-of-dock levelers for docks without pits. Detailed specs, easy mounting, and quick quote request. Ideal for warehouse upgrades.

If you’re ready to install a pitless edge-of-dock leveler (EOD) on your existing dock, our manual and electric models mount directly to the dock face with no need for excavation. They bridge height differences of ±6 inches, support safe forklift movement, and can cut loading/unloading times by 25-35%. Constructed from high-strength galvanized steel with anti-slip surfaces, they comply with OSHA safety standards and ANSI MH30.1 load ratings.

Detailed specification comparison:

We customize pricing based on your exact needs (size, accessories, volume). Volume orders qualify for significant discounts, and we offer bundles with items like wheel chocks or lights.

Installation is simple: packages include videos, templates, and anchor kits. On-site support available if needed.

If you’re evaluating options, this section covers mechanism differences, applications, customer examples, FAQs, and tips to choose.

Manual EOD uses lever and spring – no power needed. Electric EOD features hydraulic power pack with push-button control for smooth operation.

Shared benefits: anti-slip lip, bumpers, corrosion-resistant finish.

Extended comparison:

- Maintenance: Manual minimal (occasional lubrication); electric periodic hydraulic checks but faster cycles.

- Traffic suitability: Manual for lower volume; electric for higher throughput.

- Durability: Both robust, tested for hundreds of thousands of cycles.

Customer examples:

1. Small southern warehouse – manual model reduced costs with no power use.

2. Manufacturing site – electric integrated seamlessly, boosting daily efficiency.

3. E-commerce facility – mixed models optimized different zones.

4. Coastal operation – manual excelled in harsh conditions.

5. International client – electric adapted perfectly to standard power.

FAQs: