Discover GEAJIE’s versatile range of high-speed doors, tailored to meet the unique needs of various industries. From cost-effective internal doors to durable rigid high-speed doors and specialized options, our solutions are engineered to boost operational efficiency, ensure safety, and maintain environmental control in any industrial environment. Choose the right door system to keep your facility running at its best.

A high-speed door is an efficient door system specifically designed for industrial environments, aiming to facilitate rapid opening and closing to optimize workflow, enhance safety, and maintain environmental control. They are typically made from flexible or rigid materials and equipped with high-performance electric drives that enable the doors to open and close within seconds, reducing energy loss and minimizing the impact on the internal environment due to prolonged door openings.

Fast logistics should not have delays; a clean factory should be free of dust; an efficient production line should not stop; temperature-controlled buildings should not waste energy. Dustproof, insect-proof, ventilated, and quick to open—these features can coexist. High-speed doors are the optimal solution to all these challenges!

We have 3 series of PVC High Speed Door Series.

PVC high-speed doors are designed for rapid and efficient opening and closing, primarily used in industrial environments to enhance productivity and environmental control. The construction of these doors is critical for their performance, durability, and safety. Here’s an overview of the key components and construction details:

1. Door Curtain

The main body of PVC high-speed doors is constructed from high-quality, flexible polyvinyl chloride (PVC) material. This curtain is often reinforced with polyester or other fabrics to increase its tensile strength and resistance to wear and tear. The thickness of the PVC material can vary depending on the application, typically ranging from 0.8 mm to 2 mm.

2. Frame and Structure

The frame of the door is usually made from galvanized steel, aluminum, or stainless steel, providing a robust and corrosion-resistant structure that supports the door curtain. The frame design ensures stability and durability, even in harsh industrial environments.

3. Motor and Drive System

PVC high-speed doors are equipped with a powerful electric motor, which is often coupled with a frequency inverter. This allows for smooth acceleration and deceleration, reducing the mechanical stress on the door components and enabling precise control over the door speed, which can range from 0.5 to 2.5 meters per second.

4. Control System

The doors are controlled by an advanced electronic control system, which can include features such as programmable logic controllers (PLCs), remote controls, and manual push buttons. The control system allows for various operational modes, such as automatic opening via sensors or manual operation.

5. Safety Mechanisms

Safety is a priority in the construction of PVC high-speed doors. Common safety features include:

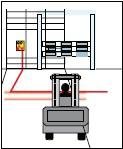

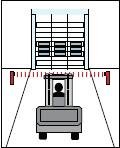

- Photoelectric Sensors: Installed along the door frame, these sensors detect the presence of obstacles and prevent the door from closing if something is in the way.

- Safety Edges: A sensitive strip at the bottom of the door curtain that triggers the door to stop and reverse if it comes into contact with an object.

- Emergency Release Mechanism: Allows the door to be opened manually in the event of a power failure or emergency.

6. Sealing and Insulation

PVC high-speed doors are designed to provide effective sealing to minimize air leakage. The sides of the door curtain are often equipped with brush seals or flexible edges that press against the frame, enhancing the door’s insulation properties and helping to maintain controlled environments.

7. Wind-Resistant Design

For outdoor applications, the doors are constructed with wind-resistant features such as wind bars or reinforcements to withstand high wind loads. This ensures the door remains operational and stable even in adverse weather conditions.

8. Optional Features

PVC high-speed doors can be customized with additional features such as:

- Transparent Panels: For increased visibility and safety.

- Insulated Panels: For enhanced thermal insulation in temperature-sensitive environments.

- Integrated Windows: To allow natural light into the space and improve visibility.

The construction of PVC high-speed doors combines flexibility, durability, and advanced technology, making them suitable for a wide range of industrial applications, from warehouses and logistics centers to cleanrooms and cold storage facilities.

Zipper Fast Doors: These doors utilize a zipper-like mechanism along the sides to create a secure and tight seal. They are particularly suited for environments requiring high levels of cleanliness and minimal air leakage, such as food processing plants and pharmaceutical facilities. Their design prevents contamination and supports strict hygiene standards.

Impact-Resistant Free-Swing Doors: Also known as traffic doors, these are flexible and impact-resistant, designed to withstand frequent collisions without damage. They are perfect for high-traffic areas like manufacturing plants and distribution centers where forklifts and pedestrians often share the same space, ensuring safety and durability.

Rigid High-Speed Doors: Built with solid materials like aluminum or steel, these doors offer superior security, insulation, and wind resistance. Ideal for external applications, they can handle extreme weather conditions and provide protection against unauthorized access, making them suitable for industrial facilities and warehouses.

Strap Fast Doors: Featuring reinforced straps for additional strength, these doors are ideal for high-traffic industrial environments that demand durability and frequent use. They are designed to resist impacts and can be easily repaired, making them an excellent choice for logistics centers and heavy-use facilities.

Economic Internal High-Speed Doors: Cost-effective and efficient, these doors are designed for interior use in environments where temperature control is not a primary concern. They help manage airflow, control dust, and noise, and separate different work areas within a facility, providing a reliable and affordable solution for warehouses and production lines.

Cold Storage Insulated High-Speed Doors: Specifically designed for cold storage and refrigerated environments, these doors feature insulated panels and rapid operation to minimize temperature fluctuations and air exchange. They help maintain strict climate control, ensuring the safety and quality of perishable goods in cold chain logistics and food storage facilities.

Selecting the appropriate high-speed door for your facility involves evaluating several key factors to ensure optimal performance, safety, and efficiency. Here’s a guide to help you make the right choice:

1. Frequency of Use

- High-Frequency Operations: If your facility experiences high traffic with frequent door cycles, such as in logistics centers or manufacturing plants, choose doors with robust motors and durable components like rigid high-speed doors or strap fast doors. These doors are designed to handle intensive use without compromising performance.

- Moderate Use: For areas with moderate traffic, such as storage rooms or internal zones, economic internal high-speed doors are sufficient. They offer the necessary speed and durability at a lower cost.

2. Location and Environmental Conditions

- Indoor Applications: For indoor use where temperature control is not critical, opt for economic internal high-speed doors or PVC curtain high-speed doors. These are cost-effective and help manage airflow, dust, and noise between different work areas.

- Outdoor Applications: In areas exposed to harsh weather or where security is a concern, consider rigid high-speed doors. They provide better insulation, wind resistance, and security against unauthorized access.

- Cold Storage: If you need to maintain strict temperature control, especially in cold storage facilities, cold storage insulated high-speed doors are the best choice. They minimize air exchange and maintain consistent internal temperatures.

3. Environmental Requirements

- Hygienic Environments: In facilities with stringent cleanliness standards, such as food processing or pharmaceutical production, zipper fast doors are ideal. Their tight seals prevent contamination and maintain a controlled environment.

- High-Traffic Impact Areas: For areas with frequent equipment and pedestrian movement, like distribution centers, choose impact-resistant free-swing doors. They can withstand collisions without damage, ensuring continuous operation.

4. Industry-Specific Needs

- Logistics and Warehousing: Choose doors that enhance efficiency and safety, such as strap fast doors or double-layer stacking doors. These doors are robust and provide good insulation and resistance to heavy use.

- Manufacturing: If your operations involve heavy machinery or sensitive production lines, opt for rigid high-speed doors for added security and durability.

- Food and Beverage: Use doors that prevent contamination and maintain cleanliness, like zipper fast doors, which offer a tight seal to keep out dust and contaminants.

5. Customization and Additional Features

- Look for doors with customizable options such as automatic operation, safety sensors, and advanced control systems. These features enhance convenience and safety, making them suitable for specialized industrial needs.

6. Maintenance and Durability

- Choose doors that are easy to maintain and built to last, especially in demanding environments. Rigid high-speed doors and strap fast doors generally require less maintenance due to their durable construction.

7. Budget Considerations

- For facilities with budget constraints, economic internal high-speed doors offer a cost-effective solution without compromising on basic functionality.

By carefully evaluating these factors based on your specific operational requirements, you can select the right high-speed door that ensures smooth workflow, safety, and energy efficiency in your facility.

1. Innovative Design

- Precision Engineering: GEAJIE high-speed doors are crafted with meticulous precision to deliver smooth and rapid operation, even under demanding industrial conditions. Their advanced mechanisms reduce operational noise and minimize wear, ensuring long-lasting performance.

- Modular Build: The modular design of GEAJIE doors allows for easy customization and component replacement, making it adaptable to various operational requirements. This flexibility simplifies repairs and upgrades, enhancing the door’s longevity and functionality.

2. Premium Materials

- Robust Construction: Built with high-quality materials like reinforced PVC, galvanized steel, and aluminum, GEAJIE doors are engineered to withstand heavy use and harsh environments. This durability makes them resilient against impacts and ensures reliable performance over time.

- Insulated Panels: For applications that require stringent temperature control, GEAJIE offers doors with insulated panels that provide excellent thermal insulation, helping to maintain a stable internal environment and reduce energy consumption.

3. Advanced Safety Systems

- Comprehensive Safety Features: Equipped with intelligent safety systems such as photoelectric sensors, safety edges, and automatic stop-and-reverse functions, GEAJIE high-speed doors protect personnel and equipment from accidents. These features ensure safe operations even in high-traffic areas.

- Wind and Pressure Resistance: GEAJIE doors are designed to withstand high wind loads and pressure changes, making them suitable for use in areas with extreme weather conditions or in high-pressure environments like cleanrooms and laboratories.

4. Operational Efficiency

- Rapid Operation: With opening speeds reaching several meters per second, GEAJIE high-speed doors significantly reduce wait times, boosting workflow efficiency and minimizing energy loss during frequent use.

- Low Maintenance Needs: Thanks to their durable construction and quality components, GEAJIE doors require minimal maintenance. This results in lower operational costs and reduced downtime, ensuring continuous productivity.

5. Customization Flexibility

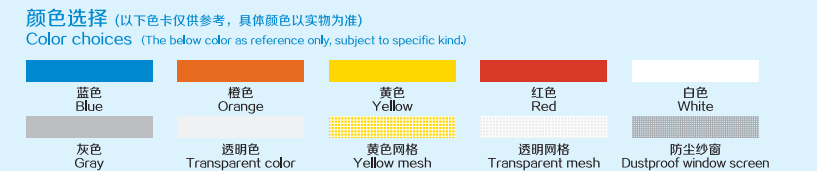

- Tailored Solutions: GEAJIE offers a broad range of customization options, including door size, material, color, and additional features such as vision panels and specialized control systems. This flexibility allows businesses to choose doors that perfectly match their operational requirements.

- Integration Capabilities: GEAJIE high-speed doors can be seamlessly integrated with existing building management and safety systems, enhancing overall facility efficiency and security.

6. Energy Efficiency

- Minimal Energy Loss: The rapid operation and tight seals of GEAJIE doors minimize air exchange, helping maintain internal temperatures and reducing the load on HVAC systems. This energy-saving design is particularly beneficial in temperature-sensitive environments such as cold storage and food processing facilities.

7. Aesthetic and Functional Design

- Modern Look: GEAJIE high-speed doors not only offer functional benefits but also contribute to the aesthetic appeal of industrial facilities with their sleek and modern design.

- Improved Visibility: Optional vision panels and transparent materials improve visibility and safety by allowing operators to see through the door, enhancing safety and communication between different work areas.

GEAJIE high-speed doors are engineered to meet the unique demands of a wide range of industrial and commercial environments. Their advanced design, robust construction, and customizable features make them suitable for various applications, ensuring efficient, reliable, and safe operations across different sectors. Here are the key applications:

1. Manufacturing Facilities

- Optimized Production Flow: In manufacturing environments, GEAJIE high-speed doors facilitate quick and seamless movement between production areas, reducing downtime and enhancing productivity. Their rapid operation and durable build are ideal for high-traffic zones where efficiency is paramount.

- Dust and Noise Control: These doors also help control dust and noise, creating a safer and more comfortable working environment for employees.

2. Warehousing and Logistics Centers

- Streamlined Operations: GEAJIE high-speed doors improve the efficiency of loading and unloading activities by providing fast and reliable access to dock areas. This minimizes delays and keeps the supply chain running smoothly.

- Environmental Management: With excellent insulation and secure sealing, these doors help maintain controlled environments, protecting goods from temperature fluctuations and contamination.

3. Cleanrooms and Pharmaceutical Facilities

- Stringent Hygiene Standards: GEAJIE high-speed doors are essential for cleanroom and pharmaceutical settings, where maintaining sterility is critical. Their tight seals and rapid closing capabilities prevent contamination, ensuring compliance with stringent hygiene regulations.

- Easy to Clean: The doors are constructed from materials that are easy to clean and sanitize, making them ideal for environments that require frequent cleaning.

4. Cold Storage and Food Processing

- Temperature Control: In cold storage and food processing applications, maintaining precise temperature is crucial. GEAJIE high-speed doors are equipped with insulated panels and tight seals to reduce air exchange and maintain stable temperatures, preserving the quality and safety of perishable goods.

- Energy Efficiency: By reducing the amount of time the doors are open, energy loss is minimized, resulting in significant cost savings and improved sustainability.

5. Automotive and Parking Facilities

- Fast Access and Security: For automotive plants and parking facilities, GEAJIE high-speed doors provide quick and secure access. Their fast operation is ideal for managing high volumes of traffic, while their robust design ensures protection against unauthorized access and environmental factors.

- Vehicle Flow Management: These doors help streamline the movement of vehicles within automotive plants, enhancing workflow and productivity.

6. Retail and Commercial Buildings

- Customer Convenience: In retail and commercial settings, GEAJIE high-speed doors offer quick and efficient access for both customers and staff. Their quiet operation and sleek design contribute to a positive shopping experience while maintaining the aesthetic appeal of the facility.

- Energy Conservation: By reducing air exchange, these doors help maintain comfortable indoor temperatures, lowering energy costs and contributing to a more pleasant environment for shoppers.

7. Agricultural and Waste Management Facilities

- Ventilation and Hygiene Control: GEAJIE high-speed doors with mesh or perforated panels provide excellent ventilation while preventing the entry of pests and debris. This is particularly beneficial in agricultural and waste management environments, where maintaining hygiene and air quality is critical.

- Durability in Harsh Conditions: Designed to withstand challenging environments, these doors offer reliable performance in facilities exposed to dirt, debris, and frequent impacts.

GEAJIE high-speed doors are versatile, efficient, and customizable, making them a perfect fit for a broad range of industrial and commercial applications. Whether it’s enhancing workflow, maintaining environmental conditions, or ensuring safety and security, GEAJIE doors are designed to meet the specific needs of various industries, contributing to improved operational efficiency and overall safety.

we give the best

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis.

friendly price

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis.

Work wholeheartedly

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis.

friendly service

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis.

Choosing GEAJIE high-speed doors means investing in a product that combines advanced technology, high-quality materials, and innovative design to deliver outstanding performance and reliability. Here are the key reasons why GEAJIE stands out in the high-speed door market:

1. Reliable Performance

- Consistent Operation: GEAJIE high-speed doors are built for demanding industrial applications, offering reliable and consistent performance even in high-frequency usage environments. Their robust construction ensures minimal downtime, reducing the impact on your daily operations.

- Long-Term Durability: Made from premium materials such as reinforced PVC, galvanized steel, and high-strength aluminum, GEAJIE doors are designed to withstand harsh conditions and heavy use. This ensures a long service life, making them a cost-effective investment for your facility.

2. Energy Efficiency

- Superior Insulation: With insulated panels and precision-engineered seals, GEAJIE high-speed doors minimize air leakage, helping to maintain stable indoor temperatures. This is crucial for facilities like cold storage units and food processing plants, where temperature control is essential.

- Reduced Energy Costs: By reducing the amount of time the doors remain open, GEAJIE high-speed doors limit energy loss, resulting in lower heating and cooling costs. This energy efficiency not only reduces operational expenses but also contributes to a smaller environmental footprint.

3. Enhanced Safety

- Advanced Safety Features: GEAJIE doors are equipped with state-of-the-art safety mechanisms, including photoelectric sensors, safety edges, and automatic stop-and-reverse functionality. These features help prevent accidents and ensure a safe working environment for employees.

- Impact Resistance: For high-traffic areas or facilities with frequent equipment movement, GEAJIE offers impact-resistant door models. These doors can withstand accidental collisions, maintaining their functionality and safety without damage.

4. Customization Options

- Tailored Solutions: GEAJIE understands that every facility has unique requirements. We offer extensive customization options, allowing you to choose from various sizes, materials, colors, and additional features like vision panels and advanced control systems. This flexibility ensures that your high-speed door meets your specific needs.

- Seamless Integration: GEAJIE high-speed doors can be easily integrated with existing building management systems and safety protocols, enhancing overall operational efficiency and security within your facility.

5. Operational Efficiency

- Rapid and Smooth Operation: GEAJIE high-speed doors are designed for fast and smooth operation, reducing waiting times and facilitating the efficient movement of goods and personnel. This helps to eliminate bottlenecks and improve productivity in busy industrial environments.

- Low Maintenance Requirements: With a focus on durability and simplicity, GEAJIE doors require minimal maintenance. This means fewer disruptions and lower long-term costs, allowing you to focus on your core business activities.

6. Versatile Applications

- Adaptable Solutions: Whether you need doors for manufacturing plants, logistics hubs, cleanrooms, or refrigerated storage, GEAJIE has a high-speed door solution that fits. Our diverse product range caters to various industrial needs, making it easy to find the right door for your application.

- Performance in Extreme Conditions: GEAJIE doors are engineered to perform reliably in diverse conditions, from high-wind areas to temperature-controlled environments, ensuring that they can meet the challenges of any operational setting.

7. Superior Aesthetics

- Modern Design: GEAJIE high-speed doors not only offer functionality but also add to the visual appeal of your facility. With a sleek, modern design, these doors create a professional and high-tech impression, making them ideal for customer-facing areas.

- Enhanced Visibility: Optional vision panels or transparent sections can be incorporated to improve visibility and natural lighting, contributing to both safety and a more pleasant working environment.

8. Environmental Sustainability

- Eco-Friendly Manufacturing: GEAJIE is committed to sustainability, using eco-friendly materials and processes in the production of our high-speed doors. This commitment helps reduce the environmental impact of our products and supports your sustainability goals.

- Energy Savings: By minimizing energy loss and improving insulation, GEAJIE doors contribute to lower energy consumption and a reduced carbon footprint, making them an environmentally responsible choice.

Conclusion

Choosing GEAJIE high-speed doors means opting for superior performance, enhanced safety, and customizable solutions tailored to your specific operational needs. With their robust construction, energy efficiency, and advanced safety features, GEAJIE doors provide a reliable, efficient, and sustainable solution for a wide range of industrial applications.

GEAJIE high-speed doors are designed to set a new standard in industrial and commercial door solutions. Here are the key features that distinguish GEAJIE from other brands:

1. Advanced Control Systems

- Intelligent Control Options: GEAJIE high-speed doors are equipped with cutting-edge control systems, allowing for precise and reliable operation. Features such as variable speed settings, soft start and stop, and programmable logic controllers (PLCs) ensure smooth and efficient door operation, tailored to specific user needs.

- Integration Capabilities: These doors can be seamlessly integrated with existing building management and automation systems, offering enhanced control, monitoring, and security for the entire facility.

2. Energy Efficiency

- High-Performance Insulation: GEAJIE high-speed doors are designed with energy-saving features such as insulated panels and tight seals. This reduces air exchange and maintains internal temperatures, which is crucial for energy-intensive environments like cold storage and food processing.

- Fast Opening and Closing: With rapid open and close speeds, GEAJIE doors minimize the time the door remains open, reducing energy loss and maintaining environmental control within the facility.

3. Compliance with Industry Standards

- Safety and Quality Certification: GEAJIE high-speed doors meet stringent international safety and quality standards, including CE, ISO, and other relevant certifications. This ensures that the doors provide a safe and reliable solution for various industrial applications.

- Environmental Compliance: GEAJIE is committed to sustainability, using eco-friendly materials and manufacturing processes that comply with environmental regulations and reduce the carbon footprint.

4. Customization Options

- Tailored Solutions for Every Need: GEAJIE offers a wide range of customization options, from door size, material, and color to specific features like vision panels, safety devices, and advanced control systems. This flexibility allows businesses to choose the perfect high-speed door solution for their unique operational requirements.

- Industry-Specific Designs: Whether it’s for food processing, pharmaceuticals, automotive, or logistics, GEAJIE high-speed doors are designed with specific industry needs in mind, offering features like impact resistance, high-speed operation, and enhanced insulation.

5. Enhanced Safety Features

- Comprehensive Safety Mechanisms: GEAJIE high-speed doors are equipped with multiple safety features, such as photoelectric sensors, safety edges, and emergency stop functions, ensuring safe and secure operation in high-traffic environments.

- Impact Resistance and Flexibility: For areas prone to collisions, GEAJIE offers doors with reinforced structures and flexible materials that can withstand impacts without compromising safety or functionality.

6. Durability and Reliability

- Robust Construction: Built with high-quality materials like reinforced PVC, galvanized steel, and aluminum, GEAJIE high-speed doors are designed to withstand harsh industrial environments and frequent use, providing long-lasting performance.

- Minimal Maintenance Requirements: Due to their high-quality construction and reliable components, GEAJIE doors require minimal maintenance, reducing operational downtime and costs over time.

7. Innovative Design and Aesthetics

- Sleek and Modern Appearance: GEAJIE high-speed doors are not only functional but also feature a modern design that enhances the visual appeal of any facility. They offer a professional and high-tech appearance that aligns with contemporary architectural trends.

- Enhanced Visibility Options: Optional vision panels and transparent door designs provide better visibility and light transmission, improving safety and aesthetics.

By combining these unique selling points, GEAJIE high-speed doors provide a superior solution that stands out in the market. They deliver exceptional performance, safety, and efficiency, tailored to meet the specific needs of diverse industrial and commercial applications.

Opting for GEAJIE high-speed doors offers a range of significant benefits, tailored to improve your facility’s operations and provide long-term value. Here are some of the key advantages:

1. Improved Workflow Efficiency

- Rapid Opening and Closing: GEAJIE high-speed doors are designed to open and close at impressive speeds, reducing wait times and minimizing interruptions to workflow. This is particularly beneficial in high-traffic areas such as warehouses, production facilities, and logistics centers, where efficiency is crucial.

- Streamlined Operations: With automated control systems, GEAJIE doors can be integrated into your facility’s operational processes, ensuring smooth and coordinated movement of goods and personnel. This automation reduces manual effort and enhances overall productivity.

2. Reduced Operational Costs

- Energy Savings: GEAJIE high-speed doors minimize the time the door remains open, which helps in maintaining indoor temperatures and reducing energy loss. This is especially important in temperature-sensitive environments like cold storage and food processing, where consistent climate control is essential.

- Low Maintenance Requirements: Built with durable materials and advanced engineering, GEAJIE doors require minimal maintenance. This reduces the frequency and cost of repairs and servicing, leading to lower operational expenses over time.

3. Enhanced Safety

- Advanced Safety Features: GEAJIE high-speed doors come equipped with a variety of safety mechanisms, including photoelectric sensors, safety edges, and automatic stop-and-reverse functions. These features help prevent accidents and injuries, providing a safer working environment for employees.

- Improved Security: For applications requiring enhanced security, such as in automotive facilities or high-value storage areas, GEAJIE doors offer robust locking systems and reinforced structures to prevent unauthorized access and protect valuable assets.

4. Customizable Solutions

- Tailored to Your Needs: GEAJIE offers extensive customization options, allowing you to select door size, material, color, and additional features that best suit your specific operational requirements. Whether you need doors for a cleanroom, a warehouse, or a food processing facility, GEAJIE can provide a solution that fits perfectly.

- Specialized Applications: For unique environments, such as high-humidity areas or places with high wind pressure, GEAJIE offers specialized door models with specific features designed to withstand these conditions, ensuring optimal performance and durability.

5. Environmental Benefits

- Sustainable Design: GEAJIE is committed to sustainability, using eco-friendly materials and manufacturing processes. By reducing energy consumption and minimizing environmental impact, GEAJIE high-speed doors contribute to a greener and more sustainable operation.

- Reduced Carbon Footprint: The energy efficiency of GEAJIE doors helps lower your facility’s carbon footprint by decreasing energy usage, which is beneficial for both the environment and your operational costs.

6. Enhanced Aesthetics and Professionalism

- Modern and Sleek Design: GEAJIE high-speed doors are not only functional but also aesthetically pleasing, with a modern design that enhances the overall look of your facility. This is especially important for customer-facing areas or facilities where maintaining a professional appearance is key.

- Increased Visibility and Natural Light: Options such as vision panels or transparent door materials can be incorporated to allow natural light into the facility and provide better visibility, improving both safety and the working environment.

7. Versatile Applications

- Broad Industry Use: GEAJIE high-speed doors are versatile and can be used across various industries, from manufacturing and logistics to cleanrooms and retail. Their adaptability makes them an ideal choice for different operational needs, ensuring that you get a door solution that aligns with your specific business requirements.

Choosing GEAJIE high-speed doors means investing in a reliable, efficient, and safe door solution that offers long-term value and performance, tailored to meet the unique challenges of your industry.

Selecting the appropriate high-speed door for your facility requires careful evaluation of various factors to ensure optimal performance, safety, and efficiency. Below is a checklist of key considerations to help guide your decision-making process:

1. Door Speed

- Opening and Closing Speed: Consider the speed at which the door operates. Faster speeds minimize airflow and temperature loss, and can enhance workflow efficiency in high-traffic areas. Typical speeds range from 20 to 100 inches per second, depending on the door type and application.

- Adjustable Speed Settings: Look for doors with adjustable speed settings to match different operational needs, allowing for flexibility in various environments.

2. Insulation Needs

- Thermal Insulation: If temperature control is critical, such as in cold storage or food processing facilities, choose doors with high insulation ratings. Insulated panels and tight seals help maintain internal temperatures, reduce energy costs, and improve product preservation.

- Sound Insulation: In environments where noise control is important, such as manufacturing plants or cleanrooms, consider doors with sound-insulating properties to minimize noise transmission.

3. Frequency of Use

- Daily Operation Cycles: Determine the number of open/close cycles the door will undergo daily. High-speed doors with durable motors and components are designed for frequent use, reducing wear and tear and ensuring longevity.

- Maintenance Requirements: Choose doors that are easy to maintain, with features like self-lubricating components and minimal wear parts, to minimize downtime and maintenance costs.

4. Safety Features

- Safety Sensors: Ensure the door is equipped with safety sensors, such as photoelectric beams or motion detectors, to prevent accidents by detecting obstructions in the door’s path.

- Emergency Stop Mechanism: Look for doors with an emergency stop function that can quickly halt the door’s movement in case of an emergency, ensuring the safety of personnel and equipment.

- Breakaway Design: For environments with high forklift or vehicle traffic, consider doors with a breakaway feature that allows the door to flex and release upon impact, preventing damage to the door and vehicle.

5. Environmental Conditions

- Wind Resistance: For outdoor applications or areas with high wind pressure, choose doors that are reinforced to withstand strong winds and maintain structural integrity.

- Humidity and Corrosion Resistance: In humid or corrosive environments, such as chemical plants or coastal areas, select doors made from corrosion-resistant materials like stainless steel or PVC to ensure durability.

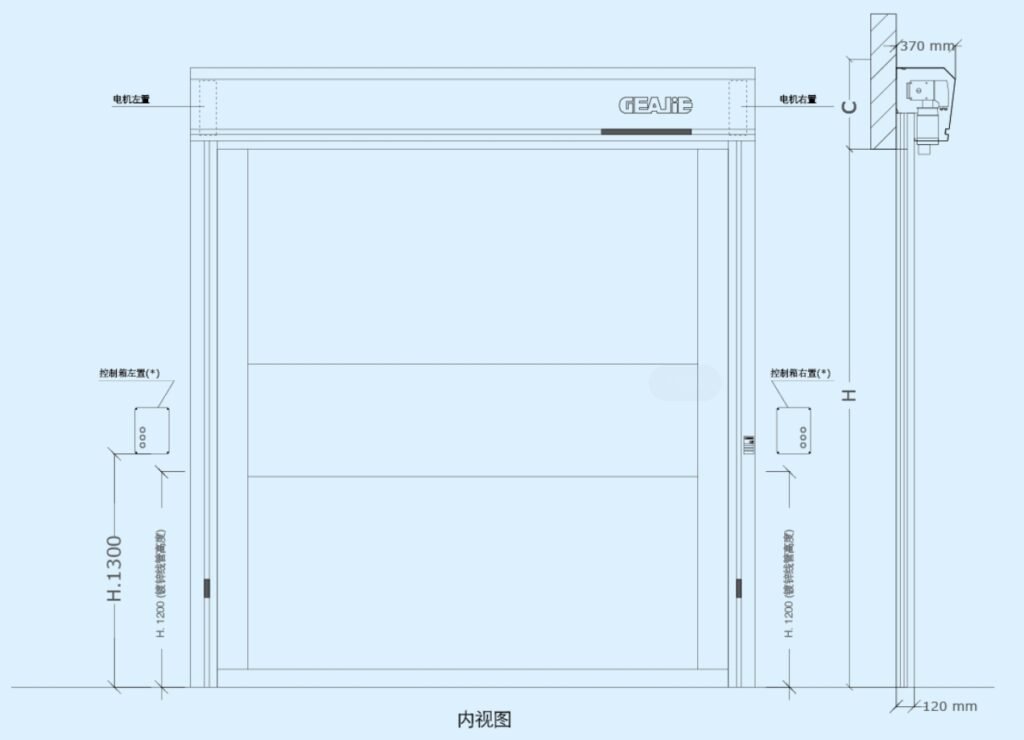

6. Operational Space

- Available Space: Assess the available space around the door opening. High-speed doors come in different configurations, such as roll-up, fold-up, or sliding designs, to fit various spatial constraints.

- Headroom and Sideroom: Consider the door’s installation requirements, including headroom (space above the door) and sideroom (space on the sides), to ensure proper fit and function.

7. Application-Specific Requirements

- Cleanroom Compatibility: For cleanroom applications, choose doors that are designed to minimize particle shedding and are easy to clean and sanitize, meeting strict hygiene standards.

- Explosion-Proof Design: In hazardous environments, such as chemical or mining facilities, opt for doors with explosion-proof certifications and materials to ensure safety compliance.

8. Aesthetic and Branding Needs

- Design and Color Options: If aesthetics and branding are important, such as in retail or customer-facing areas, select doors that offer customization in color, material, and design to match the facility’s appearance and branding requirements.

- Vision Panels: For enhanced visibility and light transmission, consider doors with vision panels or transparent sections, improving safety and aesthetics.

9. Integration Capabilities

- Automation and Control Systems: Ensure that the high-speed door can be integrated with existing automation systems, such as building management or access control systems, for seamless operation and monitoring.

- Interlocking Systems: For airlocks or controlled environments, consider doors with interlocking systems that prevent simultaneous opening of multiple doors, maintaining environmental integrity.

10. Cost Considerations

- Initial Investment: Evaluate the upfront cost of the door, including installation. While high-speed doors may have a higher initial investment, they often provide significant long-term savings through energy efficiency and reduced maintenance.

- Operational Savings: Consider the potential savings in energy costs, reduced downtime, and maintenance, which can offset the initial investment and provide a favorable return on investment (ROI) over time.

By taking these factors into account, you can choose a high-speed door that best suits your facility’s specific needs, ensuring enhanced performance, safety, and cost-effectiveness.

Let’s talk about your door needs now!Please provide the dimensions of the door opening, the application scenario, and the effect you wish to achieve. With this information, we will immediately offer you a tailored solution. Act now!

These performance features make high-speed doors an ideal choice for industrial plants, logistics centers, and food processing facilities. They not only enhance operational efficiency but also improve site safety and energy utilization efficiency.

From Design to Deployment: Ensuring Quality and Reliability

Design and Engineering

We utilize advanced CAD software to develop precise blueprints and models tailored to the specific needs of our clients for PVC high-speed doors.

Material Selection

We select high-quality materials, including durable PVC and reliable mechanical and electrical components, to ensure long-lasting performance.

Cutting and Fabrication

Advanced machinery is used to accurately cut PVC sheets and components, which are then welded and fabricated into the basic structure of the high-speed door.

Assembly

Essential parts, including fabricated components, motors, and rollers, are meticulously assembled to ensure smooth and efficient operation.

Surface Treatment

The PVC high-speed door undergoes treatments to enhance durability and resistance, including UV protection and anti-corrosion coatings.

Quality Control

Throughout the manufacturing process, we perform dimensional checks, weld inspections, and functional tests to uphold the highest quality standards.

Mechanical and Electrical System Installation

Mechanical and electrical systems are installed and thoroughly tested to ensure the high-speed doors operate smoothly and reliably.

Final Inspection and Testing

A comprehensive final inspection and testing are conducted to verify correct and safe operation, including speed tests and safety feature checks.

1.Curtain sheet:

Specification : 95 * 22mm (curtain thickness 0.8mm, 1.0mm, 1.2mm according to the size of the door body selection) color-coated steel plate roll forming, good strength, strong wind resistance, beautiful and other advantages.

|

|

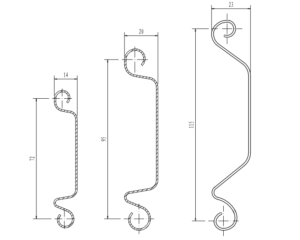

2.Track:

The special track for the roller shutter door is adopted, the thickness is 1.5mm, and the track is equipped with EPDM silencing rubber strip, which has better mute effect, and its size head design can ensure the smooth operation of the curtain in the track, and the noise is low.

Specification:100×95×1.5mm(track thickness 1.5mm), galvanized sheet bending.

|

|

3.Bottom beam:

It is made of galvanized steel, which is better than the rough bottom beam made of angle iron, and the bottom is equipped with a specially designed sealing strip to make the door completely sealed with the ground when closed, which can prevent dust, wind and rain from invading, etc., even if the ground is uneven.

The bottom beam is made of galvanized steel, specification: 80mm×40mm;

|

|

4.Reel:

According to the size of the door, the diameter of the reel can be 160, 219, etc., and the thickness is 2.0mm;

|

|

5.Box:

It is made of 0.8mm thick color steel plate by bending, and the surface is white spraying.

|

|

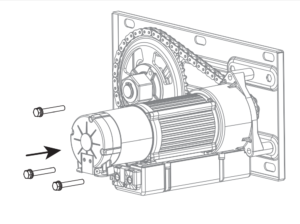

6.Motor:

Motor/chain high-quality motor, stable operation, in case of power failure, the chain can be pulled manually to open and close the rolling door.

|

|

Speed: The door lifting and closing speed is 5-7 m/min.

Control mode: configure remote control switch, fixed button, can be manual after power failure

Performance: full perspective design, to achieve the effect of window advertising, for the first choice of shops in the bustling area of the city, smooth operation, low noise, beautiful anti-theft, corrosion resistance, simple and elegant design, noble and elegant appearance.

7.Door body structure:

8.Parameter:

Number | Component Name | Specification and mode | Remark |

1 | High-strength high-quality color-coated steel sheet roll forming | 115*22*(0.8~1.2mm) |

|

2 | Galvanized track+EPDM sound-absorbing strip | 100×95×1.5 |

|

3 | Rolling door motor | 600∽1000㎏、220V |

|

4 | Roller beam tube | φ165×2.0mm |

|

5 | Box (box cover) | 0.7mm steel plate bent into shape |

|

Geajie Industry ensures that our products' quality and performance remain industry-leading.

What industries can benefit from Geajie's products?

Geajie’s products are designed to serve a wide range of industries including logistics, manufacturing, food processing, retail, and more, offering solutions that enhance efficiency, safety, and sustainability.

How do Geajie's dock levelers improve operational efficiency?

Our dock levelers streamline the loading and unloading process, reducing downtime and facilitating smoother transitions of goods, which in turn boosts overall operational speed and reduces costs.

Are Geajie's industrial doors customizable?

Yes, Geajie’s industrial doors are customizable to meet specific operational requirements, including size, material, and integrated technology features, ensuring a perfect fit for every facility.

What safety features are included in Geajie's products?

Geajie’s products come equipped with various safety features, including emergency stop functions, anti-crush mechanisms, and safety sensors, all designed to protect employees and assets.

How do Geajie's dock seals contribute to energy efficiency?

Our dock seals create an airtight seal when a truck is docked, preventing air leakage, enhancing thermal efficiency, and leading to significant energy savings and reduced environmental impact.

Can Geajie provide customized solutions for unique industrial challenges?

Absolutely, Geajie specializes in developing customized solutions tailored to address the unique challenges and requirements of different industrial settings, ensuring optimal performance and satisfaction.

What post-purchase support does Geajie offer?

Geajie offers comprehensive post-purchase support, including installation, maintenance, and repair services, ensuring that our products continue to operate efficiently and effectively over their lifespan.

How does Geajie ensure the quality and durability of its products?

We adhere to strict quality control processes, use premium materials, and conduct rigorous testing on all our products to ensure they meet the highest standards of quality and durability.

High-Speed Door: Efficiency and Performance for Your Facility

Enhancing Efficiency and Safety in Industrial and Commercial Environments