Our zipper fast doors are designed for high-traffic industrial environments, providing fast operation, enhanced safety, and self-repairing technology. With their durable construction and zipper system, these doors are perfect for warehouses, production areas, and distribution centers where efficiency and reliability are critical.

Certifications and Safety Assurance

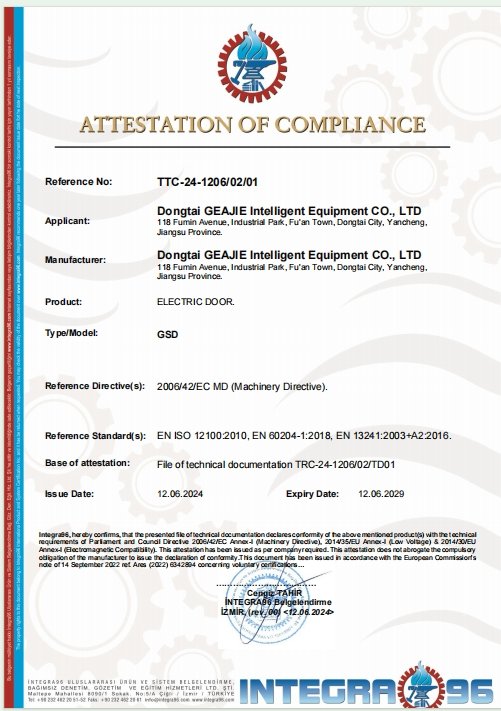

CE Certified: Our zipper fast doors comply with European safety, health, and environmental standards, ensuring reliable and safe operation. Warranty: Backed by a [X-year] warranty, ensuring the long-term performance and durability of your doors.

Fast, Reliable, and Built for High-Performance Environments

Looking for a solution that enhances workflow and energy savings? GEAJIE zipper fast doors are designed for rapid operation, self-repairing functionality, and superior durability, making them perfect for busy, temperature-controlled environments. With CE certification and customizable options, our doors ensure safety, efficiency, and long-lasting performance. Upgrade your facility today with doors that keep your operations running smoothly and efficiently.

How Zipper Fast Doors Work: Zipper fast doors feature a unique zipper mechanism that ensures a tight seal while enabling the door to reset itself after being dislodged from the tracks. This self-repairing capability reduces downtime and ensures continuous operation in high-traffic areas.

Customization Options: Available in a variety of sizes, colors, and materials, our zipper fast doors can be tailored to suit the specific requirements of your facility, including options for insulation and soundproofing.

What industries are zipper fast doors suitable for?

Can these doors help with temperature control?

How does the self-repairing feature work?

Are these doors weather-resistant?

Do you offer automated options?

How easy is maintenance?

What is the lead time for delivery?

How long is the warranty?

Success Story 1

Case Study 1: Improving Efficiency at a Pharmaceutical Distribution Center Client Background: A large pharmaceutical distribution center needed a high-performance door solution for its cold storage areas, where precise temperature control was crucial for maintaining the quality of sensitive medications and vaccines. The facility faced frequent door use, leading to temperature fluctuations, energy loss, and occasional door malfunctions during busy loading and unloading times. Client’s Requirements: The client sought a door solution that could open and close quickly to reduce energy loss, withstand heavy use, and self-repair in case of accidental impact. Additionally, maintaining a controlled environment was critical to the safety and effectiveness of their stored products. Solution Provided: We installed GEAJIE Zipper Fast Doors at the cold storage entry points. The doors' high-speed operation helped reduce the time the doors were open, maintaining a stable temperature inside the storage area. The self-repairing zipper mechanism automatically realigned the doors after any accidental dislodgement, reducing downtime and maintenance needs. With built-in safety sensors, the doors provided a secure environment, preventing accidents during high-traffic periods. Results: Post-installation, the distribution center achieved a 15% reduction in energy costs due to better temperature control and minimized door-open time. The self-repairing function greatly improved operational uptime, with zero disruptions caused by door malfunctions. As a result, the facility maintained the ideal environment for pharmaceuticals, ensuring product safety and compliance with regulations. The client was pleased with the improved efficiency and safety, and they plan to expand the use of GEAJIE doors to other facilities.

Success Story 2:

Case Study 2: Enhancing Workflow in an Automotive Manufacturing Plant Client Background: An automotive manufacturing plant faced challenges with their existing doors in the production area, where rapid movement of materials and components was essential. The facility’s previous doors were slow and prone to damage from frequent impacts, causing delays and increasing maintenance costs. Client’s Requirements: The client required fast-operating doors that could handle heavy traffic without frequent maintenance. They also needed doors that could self-repair to prevent downtime from accidental impacts in the fast-paced production environment. Solution Provided: We installed GEAJIE Zipper Fast Doors throughout the manufacturing floor. These doors featured high-speed opening and closing to maintain smooth material flow and reduce downtime. The self-repairing design allowed the doors to reset themselves when knocked out of the tracks, ensuring uninterrupted operations. In addition, the durable material construction made the doors resilient to the heavy demands of the production environment. Results: The manufacturing plant experienced a 20% increase in workflow efficiency as the high-speed doors allowed for faster movement of materials between production zones. The self-repairing feature minimized downtime, as doors were able to realign themselves without manual intervention. The facility also saw a significant reduction in maintenance costs, as the doors withstood the high-impact environment with ease. The client expressed satisfaction with the improved production efficiency and cost savings, with plans to install more GEAJIE doors in other parts of the plant.

High-Speed Opening and Stable Operation: Are you looking for doors that open quickly and operate smoothly, designed with a collision-resistant concept to prevent damage from accidental impacts?

Aesthetic and High Sealing Performance: Do you need a door with a sleek appearance and excellent sealing capabilities that ensures stable operation and minimizes maintenance costs?

Low Maintenance Costs: Are you concerned about reducing maintenance costs while maintaining a door with high sealing performance?

Compatibility with Various Control Signals: Do you require doors that can connect to various control signals for enhanced operational flexibility?

Manual Operation and Backup Power Options: Are you looking for doors that can be manually operated or equipped with a backup power supply to ensure functionality during power outages?

Suitable for High-Demand Environments: Do you need doors specifically designed for high-precision manufacturing, food processing, electronics, pharmaceuticals, or other environments with high sealing requirements and frequent access?

- The one-piece door curtain and specially designed soft bottom edge effectively prevent damage from accidental impacts.

- The special zipper design on both sides of the door curtain ensures a high level of sealing with the tracks.

- The multifunctional intelligent variable frequency control system features a human-machine interface and can connect to various external control signals.

- In case of emergencies, the door curtain can be manually opened, and a backup power supply can be added to enable door operation during power outages.

Zipper fast doors are an excellent choice for various industrial and commercial environments, especially where there are strict requirements for speed, sealing, and safety. Here are the key reasons to choose zipper fast doors:

Adjustable High-Speed Operation Zipper fast doors offer an adjustable opening speed ranging from 1.2 to 2.0 meters per second. This rapid operation significantly enhances logistics efficiency by reducing waiting times for passage, making them ideal for areas with frequent door use, such as warehouses, production facilities, and transport corridors.

Exceptional Sealing Capabilities The combination of zipper track technology and door curtain ensures a superior seal, effectively preventing air leakage and the ingress of contaminants. Unlike traditional sealing methods that use blades or brush systems, these doors maintain temperature more effectively, optimizing energy efficiency and reducing overall energy consumption.

Self-Repairing Feature to Minimize Maintenance Costs Equipped with a “re-engagement” system, or an automatic derailment repair function, zipper fast doors can automatically reset to their original position without manual intervention if they are displaced due to impact. This self-repairing capability significantly cuts down on maintenance time and costs, enhancing the door’s longevity and reducing downtime.

Enhanced Safety Features The doors are designed with flexible and resilient curtains, with no weighted bottom parts. This means that even in emergencies, if someone accidentally collides with the door, the risk of injury is minimized. This design greatly improves operational safety, making it especially suitable for high-traffic and high-risk environments.

Innovative Dual-Shaft System The dual-shaft system in zipper fast doors provides unparalleled security and airtightness. Unlike traditional fast doors that rely on the weight at the bottom of the curtain for closure, zipper fast doors utilize a dual-shaft system that meshes perfectly with the curtain’s zipper teeth, ensuring a swift and secure closure without the need for rigid components, thus reducing wear and maintenance needs.

Extended Durability Zipper fast doors are made from highly durable materials, with robust and flexible curtains capable of withstanding over a million opening and closing cycles. In practical applications, some products have even achieved up to 5 million cycles, greatly extending the door’s service life and minimizing the need for replacements and repairs.

Versatile Applications Zipper fast doors are ideal for industries with high hygiene and sealing requirements, such as food and beverage, electronics, pharmaceuticals, printing and packaging, and warehousing. They are particularly suited for environments that require frequent opening and closing, effectively isolating different spaces, maintaining cleanliness, and enhancing operational efficiency.

Choosing zipper fast doors can greatly improve the efficiency and safety of your workspace, reduce operating costs, and provide superior durability and sealing performance. They are the ideal door solution for modern industrial and commercial facilities.

Zipper high-speed doors are commonly used in industrial and commercial settings, especially in areas with frequent traffic, requiring high sealing and fast operation, such as food processing plants, warehouses, and pharmaceutical manufacturing facilities. These doors are designed with an auto-repair feature that allows them to automatically reset after impact, minimizing downtime and reducing maintenance costs. Here are the steps and precautions for properly operating a zipper high-speed door to ensure safe and efficient use.

1. Inspect the Door Condition

- Before use, inspect the overall condition of the door to ensure there are no tears, cracks, or other damage to the door curtain.

- Check the tracks and guiding system to ensure they are free of obstructions and wear, and that all components are functioning properly.

- Verify that all safety devices, such as photoelectric sensors, emergency stop buttons, and safety edges, are operational, and that all control panel buttons and indicator lights are working correctly.

2. Prepare the Operating Area

- Clear the area around the door, removing any items that could obstruct the door’s movement, such as stacked goods, tools, or equipment.

- Ensure there are no obstacles or personnel in the door’s path to prevent accidents during opening or closing.

3. Activate the Control System

- Ensure the power supply is connected correctly and activate the door’s control system.

- Use the “Up” or “Down” buttons on the control panel to operate the door, and check the indicator lights to ensure the equipment is functioning normally.

4. Operate the Door

- Press the “Up” button to slowly raise the door to the desired height, ensuring it moves smoothly along the tracks without sticking.

- When the door is fully open, make sure it stays in a safe position to prevent accidental closing.

- To close the door, press the “Down” button to lower it slowly to the fully closed position, ensuring the path is clear of any obstacles.

5. Ensure the Door is Securely Locked

- After the door is closed, check that the safety edge and locking mechanisms have properly engaged to prevent the door from opening unexpectedly.

- Confirm the door is securely locked and check the lock status indicator light for a secure display.

6. Auto-Repair Function

- If the door curtain becomes dislodged or impacted during operation, the zipper high-speed door’s auto-repair feature will automatically guide the curtain back into the tracks. Wait until the door has returned to its normal position before continuing operation.

- Avoid standing near the curtain during the auto-repair process to prevent interference or injury.

7. Perform Regular Inspections and Maintenance

- Regularly inspect the door’s components, including the curtain, tracks, guides, and seals, to ensure they are not damaged or worn.

- Lubricate the tracks and moving parts to maintain smooth operation, and check that all fasteners and bolts are secure.

- Periodically test all safety devices, such as photoelectric sensors, safety edges, and emergency stop buttons, to ensure they function properly when needed.

8. Shut Down the System and Clean the Area

- After use, shut down the control system and disconnect the power supply to prevent accidental activation.

- Clean the operating area, removing all tools and obstacles to keep the area tidy and ready for the next use.

Precautions

- Always wear appropriate personal protective equipment, such as safety shoes and gloves, when operating the door.

- Avoid standing under the door while it is moving to prevent accidents.

- Ensure all operators are trained and familiar with the door’s operating procedures and safety guidelines.

- If any abnormalities are detected during operation, such as unusual noises or difficulty moving, stop using the door immediately and contact a professional technician for inspection and repair.

By following these steps and precautions, you can ensure the safe operation of a zipper high-speed door, extend its service life, and improve efficiency.

In an emergency, the door curtain can be manually opened, and an optional backup power supply can be added for use during power outages.

The full curtain and specially designed soft bottom edge effectively prevent damage from accidental impacts.

he unique zipper design on both sides of the door curtain ensures a high level of sealing with the track.

A multifunctional intelligent variable frequency control system with a user-friendly interface that can connect to various external control signals.

We have a team of highly skilled and experienced professional workers who are dedicated to delivering top-quality results and ensuring that every project is completed with precision and excellence.

Our project is currently on time and progressing smoothly, with all milestones being met as scheduled and no delays anticipated.

We are always friendly and eager to serve our customers, ensuring that every interaction is met with warmth, professionalism, and a genuine commitment to meeting their needs and exceeding their expectations.

We are committed to providing the best and most fair service, ensuring that every customer receives top-quality solutions at competitive and equitable prices, reflecting our dedication to integrity and customer satisfaction.

we give the best

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis.

friendly price

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis.

Work wholeheartedly

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis.

friendly service

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis.

Designed for Precision and Reliability in Demanding Environments

Product Characteristics

Adopting the latest curtain anti-collision design concept, it features an elegant appearance, excellent sealing, smooth operation, and low maintenance costs, making it a product with outstanding sealing performance.

The entire curtain features a specially designed soft bottom edge, effectively preventing damage from accidental collisions.

The multifunctional intelligent variable frequency control system, with a user-friendly interface, can connect to various external control signals.

The curtain sides are equipped with a unique zipper design that ensures a high level of sealing with the tracks.

In the event of an emergency, the curtain can be manually opened, and an additional backup power supply can be installed to allow operation during power outages.

| Application Environment | Doors for Indoor Use in Normal Temperature Environments |

|---|

| Size Range | Width: 1000-5000mm Height: 1000-5000mm |

| Opening/Closing Speed | Opening speed: 1.2m/s, Closing speed: 0.8m/s |

| Curtain | High-strength polyester fiber PVC curtain, standard thickness 0.8mm, other thicknesses available |

| Curtain Color | Yellow, Orange, Blue |

| Window | Standard one-row window, thickness 1.5mm |

| Track | Standard polymer sliding track, galvanized track cover, color spraying available, stainless steel option available |

| Roller & Motor Cover | Standard steel cover, color spraying available Stainless steel option available |

| Optional Opening Modes | Three-key button, remote control, geomagnetic, radar, pull cord, etc. |

| Safety Device | Standard wireless safety bottom edge and track safety protection photoelectric sensor |

| Motor & Reducer | German Lenze, 220V/380V, 0.55-1.5kw Other brands available |

| Control System | PLC and frequency converter |