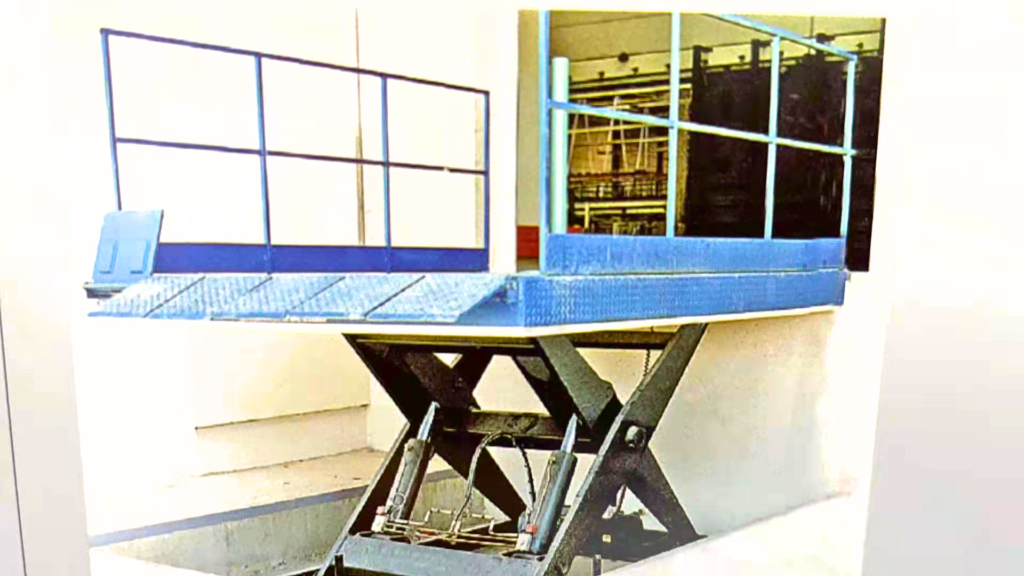

Our scissor dock levelers provide a stable, durable solution for heavy-duty cargo handling. With a hydraulic lifting system, they ensure fast and efficient loading operations, boosting productivity in warehouses and factories.

What Our Customers Have to Say

Custom Solutions for Efficient, Heavy-Duty Cargo Handling

Not sure which option is right for you? Our scissor dock levelers offer both standard and custom solutions, designed to meet your unique operational needs. With powerful hydraulic lifting and robust construction, these platforms are ideal for optimizing your loading efficiency. Explore how they can enhance your warehouse or industrial operations.

How It Works: The scissor dock leveler operates with a hydraulic system, and the scissor mechanism ensures platform stability during lifting and lowering, ideal for handling various heavy loads.

Customization Options: We offer custom sizes, load capacities, and surface finishes to meet the specific needs of different industries.

Scissor dock levelers are ideal for logistics, manufacturing, and warehousing industries, particularly for frequent heavy-duty cargo handling.

Scissor dock levelers can support up to [X tons], ensuring safety in heavy industrial applications.

- Yes, scissor dock levelers are designed with a durable hydraulic system and require minimal daily maintenance, ensuring stable operation.

- Yes, the platforms are ISO certified and meet international safety and quality standards, ensuring operator safety.

- The platform is made from corrosion-resistant materials and can function in extreme weather conditions, making it suitable for outdoor and special environment operations.

- Standard scissor dock levelers are usually in stock, while custom models have delivery times based on specific needs, typically within [X days].

- Yes, we provide custom options for different sizes and load capacities to meet the unique application needs of our customers.

- No, the scissor dock leveler features an intuitive control system that is easy to operate, requiring no complex training. Operators can get up to speed quickly.

Customizable Specifications and Load Capacities: Are you looking for a solution that can be customized to your specific needs in terms of size and load capacity?

Simple and Safe Operation: Do you need a platform with constant pressure and button-operated controls that simplify all operational processes while ensuring safety?

Suitable for Trucks of Various Heights: Are you seeking a platform that is suitable for loading and unloading goods from trucks of different heights?

Cross-Floor Goods Transportation: Do you require a solution that can facilitate the transportation of goods across multiple floors?

Customizable Explosion-Proof Options: Are you looking for a customizable platform that can be made explosion-proof for specific applications?

High Reliability and Low Maintenance: Are you interested in a product that offers high reliability and requires minimal maintenance?

- Improved Operational Efficiency: With hydraulic power and automatic lifting, the scissor dock leveler can quickly and efficiently complete loading tasks, reducing manual intervention. Lower Long-Term Maintenance Costs: The platform is designed for durability, and the hydraulic system requires minimal maintenance, reducing long-term maintenance costs.

- Specifications and load capacity can be customized according to usage requirements.

- Constant pressure, button-operated controls allow for all functions to be easily and safely managed.

- Suitable for trucks of various heights. .

- Capable of transporting goods across different floor levels

- Explosion-proof models can be customized.

- Highly reliable with minimal maintenance.

A scissor lift platform is an efficient, safe, and versatile loading and unloading solution, particularly suited for warehouses and logistics centers where there is a significant height difference to overcome. Here are the main reasons to choose a scissor lift platform:

Easy Operation

The scissor lift platform is easy to operate; simply press the lift button to raise the platform to be level with the ground, facilitating the loading and unloading of goods or allowing forklifts to drive onto the platform. The platform can also be adjusted to the height of the truck bed, ensuring a smooth and efficient loading and unloading process.Simple Installation

This platform requires minimal installation space, needing only about a 3000*1800mm area. It does not require additional dock height support and can be installed by digging a pit directly into the ground, making the installation process quick and adaptable.High Load Capacity

The scissor lift platform has a strong load capacity, capable of carrying 2-3 tons at a time, making it suitable for handling large volumes of goods. A single truck can typically be loaded or unloaded in just 3-5 operations, greatly increasing efficiency.Reduced Labor Costs

Using a scissor lift platform can reduce the need for manual labor, typically reducing the workload by 3-4 workers. This not only lowers labor costs but also improves overall operational efficiency.Long-Lasting Durability

The platform is built to be robust and durable, capable of withstanding heavy use. Even with up to 1000 uses per month, it can last over five years, demonstrating its reliability and reducing the need for frequent replacements and maintenance costs.High Safety Standards

The scissor lift platform is equipped with upper and lower limit switches to prevent operation beyond safe limits. Additionally, it can be fitted with anti-shear devices, ensuring the platform stops automatically if a person or object enters beneath it, providing additional safety to prevent accidents.

Choosing a scissor lift platform not only meets various loading and unloading needs and improves operational efficiency but also ensures safety and reduces operational costs, making it an ideal solution for logistics and warehouse operations.

A scissor lift dock leveler is a vertical lifting device designed for loading and unloading goods between different heights. It is ideal for warehouses, logistics centers, and industrial facilities where significant height adjustments are required. Here are the steps and precautions for using a scissor lift dock leveler to ensure safe and efficient operation.

1. Inspect the Platform Condition

- Before using the lift, inspect the overall condition of the scissor lift dock leveler. Ensure the platform surface, scissor mechanism, and hydraulic system are free from damage or excessive wear.

- Check the hydraulic cylinders and hoses for any leaks or damage, and ensure the hydraulic fluid level is within the normal range.

- Verify that all safety devices, such as safety rails and limit switches, are functioning properly.

2. Prepare the Loading Area

- Clear the platform and surrounding area of any objects that could obstruct operations, such as tools, packaging materials, or debris, to ensure a safe working environment.

- Make sure the truck is properly positioned near the platform and use wheel chocks to secure the truck to prevent any movement during loading or unloading.

3. Activate the Platform

- Turn on the power supply and activate the hydraulic system, checking that all indicators and displays on the control panel are functioning correctly.

- Press the “up” button on the control panel to raise the platform to the desired height, aligning it with the truck bed or loading area.

4. Adjust and Secure Platform Height

- Adjust the platform height using the control panel to match the truck bed or loading area’s height, ensuring a safe and stable bridge for loading and unloading.

- Ensure the safety rails are properly raised to prevent falls during operation.

5. Perform Loading and Unloading Operations

- Once the platform is correctly positioned, use forklifts or other handling equipment to load or unload goods.

- During operations, ensure the weight is evenly distributed across the platform to avoid overloading one side or causing the platform to tilt.

6. Lower the Platform

- After loading or unloading, press the “down” button on the control panel to lower the platform slowly back to the ground or its initial position.

- Ensure the platform returns to its resting position and turn off the power supply to prevent accidental operation when unattended.

7. Clean and Secure the Area

- Clean the platform and surrounding area, removing all tools and debris to ensure the area is tidy and ready for the next use.

- Verify that all equipment and safety devices are in the off and locked position.

8. Regular Inspection and Maintenance

- Regularly inspect the scissor lift dock leveler, including checking hydraulic fluid levels, lubricating moving parts, and replacing worn components.

- Check all scissor structures, hydraulic cylinders, and connections to ensure there is no wear or other potential issues.

Safety Precautions

- Always wear appropriate personal protective equipment, such as safety shoes and gloves, when operating the platform.

- Do not exceed the platform’s maximum load capacity to avoid damage or accidents.

- Ensure all operators are trained and familiar with the platform’s use and safety requirements.

- If any malfunction or abnormal condition is detected, stop using the equipment immediately and contact a professional technician for repairs.

By following these steps and precautions, you can ensure safe and efficient use of the scissor lift dock leveler, enhance loading and unloading efficiency, and protect the safety of both goods and personnel.

Case 1: Logistics Center Increases Efficiency

A large logistics company improved cargo handling efficiency by 30% using scissor dock levelers, reducing loading time and lowering the accident rate.

Case 2: Manufacturing Company Optimizes Production Flow

A global manufacturer implemented custom scissor dock levelers, reducing cargo handling time and increasing overall production efficiency, cutting downtime by 25%.