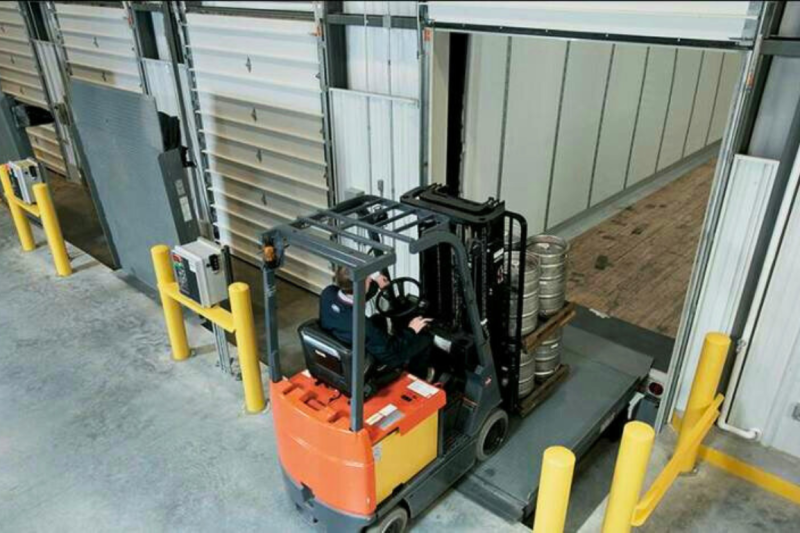

Our mechanical dock levelers require no hydraulic or electrical components, featuring a simple manual operation design suitable for heavy-duty loading needs. These platforms are built for durability and ensure efficient, stable loading operations with minimal maintenance.

Let us go forward in this battle fortified by conviction that those who labour in the service of a great and good cause will never fail.

How It Works: The mechanical dock leveler adjusts height via a manual lever, requiring no power or hydraulic systems, making it easy to operate and maintain.

Customization Options: We offer customization in size and load capacity to meet the specific needs of different industries.

Loading and Unloading Platforms for Non-Powered Locations: Are you looking for loading and unloading platforms suitable for non-powered locations that can work in conjunction with other electric platforms to ensure normal operation even during power outages?

Unique Balance System: Do you need a platform with a unique balance system that ensures a smooth and continuous lowering process?

Improved Loading and Unloading Efficiency: Are you looking to streamline the loading and unloading process to make it more convenient and faster, thereby improving logistics efficiency?

Meeting Different Load Capacity Requirements: Do you require a platform that can meet various load capacity needs?

- Suitable for non-powered locations, it can be combined with other electric platforms to ensure normal operation during power outages.

- The unique balancing system ensures a smooth and continuous lowering process.

- Maintenance requirements are relatively high.

A mechanical dock leveler is a highly durable, reliable, and cost-effective loading solution, particularly suitable for locations without power or for use in combination with other hydraulic dock levelers. Here are the main reasons to choose a mechanical dock leveler:

Exceptional Durability and Reliability

The mechanical dock leveler is built with a robust design, using a spring balance system and high-strength materials to ensure long-term, reliable operation. Its sturdy structure reduces the need for frequent maintenance, lowers overall operating costs, and extends the lifespan of the equipment.Ideal for Non-Powered Environments

Mechanical dock levelers are perfect for facilities without an electrical supply. They use a spring balance system to lift the main deck, making operation simple and easy. Even during power outages, loading and unloading can continue uninterrupted, ensuring continuity in production and logistics, which helps improve productivity.Simple and Safe Operation

The platform is designed for ease of use; the operator only needs to pull a chain to activate the spring balance system and lift the deck. The lip extends automatically as the platform rises, ensuring safe and reliable loading and unloading, minimizing potential operational risks.Protective and Safety Features

The retractable lip design of the mechanical dock leveler effectively prevents damage to the platform when trucks back into the dock. The unique balancing system ensures a smooth and controlled lowering process, reducing the risk of equipment damage due to improper operation and enhancing overall safety.Flexible Adaptability for Various Loading Environments

This platform can operate below dock level, increasing loading flexibility and adapting to various cargo handling needs. Whether dealing with lower trucks or specific scenarios requiring the platform to lower below dock height, the mechanical dock leveler provides a suitable solution.

Choosing a mechanical dock leveler provides a non-electric, easy-to-use, and safe loading solution, suitable for various logistics and warehousing environments. It ensures efficient and secure loading and unloading operations, making it an excellent choice for optimizing workflow.

A mechanical dock leveler is a manual loading dock device that bridges the height difference between a dock and a truck bed, facilitating safe and efficient loading and unloading. Unlike hydraulic or air-powered levelers, mechanical dock levelers use a spring and lever system, making them a cost-effective and reliable option for many facilities. Here’s how to properly operate a mechanical dock leveler, along with key safety guidelines.

1. Inspect the Dock Leveler

- Before operation, inspect the dock leveler for any signs of damage, wear, or obstruction. Ensure that the platform, lip, and frame are intact and in good condition.

- Check the springs and lever mechanisms for wear or damage. Verify that all safety features, including locks and safety legs, are operational.

- Clear the surrounding dock area of any debris or obstacles that could interfere with the operation.

2. Prepare the Loading Area

- Make sure the loading area is clear of any objects that might impede the dock leveler’s operation.

- Position the truck so that it is squarely aligned with the dock and centered with the dock leveler.

- Secure the truck with wheel chocks to prevent movement during loading and unloading.

3. Operating the Mechanical Dock Leveler

- Pull the release chain or use the activation mechanism to unlock and release the dock leveler platform. The platform will rise due to the spring tension.

- When the platform is fully raised, guide it down by pulling the chain, allowing the lip to extend and rest securely on the truck bed, forming a stable bridge.

- Ensure that the lip is securely positioned on the truck bed, preventing any gaps or movement during loading or unloading.

4. Perform Loading and Unloading

- Once the dock leveler is securely in place, begin loading or unloading operations. Use forklifts, pallet jacks, or other equipment to transfer goods safely between the truck and the dock.

- Operate equipment smoothly and steadily to avoid accidents or damage to goods and equipment.

5. Stow the Dock Leveler

- After completing loading or unloading, return the dock leveler to its resting position.

- Pull the release chain to lift the platform, then guide it back down gently until it rests flush with the dock floor.

- Ensure that the lip retracts fully and the platform is securely stowed in its storage position.

6. Secure the Dock Area

- Close the dock door once the dock leveler is stowed to secure the loading area and prevent unauthorized access.

- Make sure the area is clear of debris or obstacles before closing the door.

7. Perform Regular Maintenance

- Regularly inspect the mechanical dock leveler, including checking the springs, levers, and platform for signs of wear or damage.

- Lubricate moving parts regularly to maintain smooth operation and prevent rust or corrosion.

- Keep a maintenance log to document all inspections, repairs, and maintenance work.

Safety Tips

- Always wear proper personal protective equipment (PPE), such as safety shoes and gloves, when operating the dock leveler.

- Do not exceed the dock leveler’s maximum load capacity to prevent damage or accidents.

- Ensure all operators are trained in the proper use of the dock leveler and understand all safety guidelines.

- If the dock leveler malfunctions or behaves unexpectedly, stop using it immediately and contact a technician for repairs.

By following these steps and safety tips, you can safely and effectively use a mechanical dock leveler, ensuring smooth loading operations while minimizing risks to people and equipment.

These platforms are ideal for logistics, warehousing, and manufacturing industries, especially in environments with limited power supply or frequent loading and unloading operations.

No, the operation is straightforward. The platform height is adjusted using a manual lever, requiring no specialized training, allowing any operator to use it with ease.

Our mechanical dock levelers can support up to [X tons], making them suitable for a wide range of industrial applications.

Mechanical dock levelers do not require hydraulic oil or electricity, making them more cost-effective in terms of maintenance. They also offer reliable, stable operation in environments where electrical power is limited or unavailable.

No, mechanical dock levelers are designed with fewer moving parts, which means less frequent maintenance and reduced downtime, saving both time and costs.

We offer a range of customization options, including different sizes, load capacities, and finishes, tailored to meet the specific needs of various industries.

Yes, these platforms are built with high-strength materials that make them durable and capable of functioning effectively in both indoor and outdoor environments, even under harsh conditions.

Standard models are typically in stock and ready for immediate delivery, usually within [X days]. Custom models may require additional lead time depending on specific requirements.

Reduced Maintenance Costs: The mechanical dock leveler’s simple design eliminates the need for complex maintenance or costly part replacements, significantly reducing long-term operational costs.

Improved Operational Efficiency: With quick manual operation, the platform can easily adjust height, improving loading efficiency and reducing both operation time and labor costs.

Case 1: Logistics Center Increases Efficiency

A logistics company implemented mechanical dock levelers in their warehouse, increasing cargo handling efficiency while reducing reliance on powered equipment. The platform’s simple design made operations more reliable and lowered daily maintenance requirements.

Case 2: Manufacturing Company Lowers Maintenance Costs

A large manufacturing company adopted mechanical dock levelers and saw a 30% reduction in maintenance costs while improving operational efficiency. The platform’s lack of hydraulic oil and complex components led to almost no downtime.