When it comes to streamlining your loading and unloading operations, every detail matters. Our advanced loading dock house solutions are designed to create a seamless transition between your facility and incoming trucks, reducing energy loss, protecting your goods, and ensuring smooth, efficient workflows. Engineered with durable materials and customizable features, these structures provide robust protection against weather, contaminants, and temperature fluctuations. Ready to elevate your loading dock performance? Discover the perfect solution tailored to your business needs today!

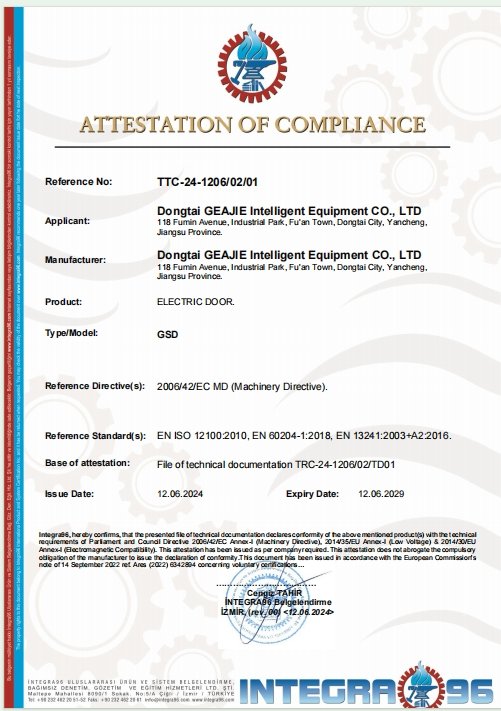

CE Certified: Our stacking doors adhere to European safety and quality regulations, offering you the assurance that they meet rigorous industry standards. Warranty: We provide a [X-year] warranty, ensuring the long-term performance and durability of your doors.

Protect Your Facility and Boost Efficiency in Every Loading Cycle

Ensure your loading and unloading processes run smoothly, no matter the weather, with our high-performance loading dock houses. Designed to create a controlled and secure connection between your facility and incoming trucks, these structures offer unmatched protection against rain, wind, snow, and extreme temperatures. Engineered for durability and adaptability, they accommodate various truck sizes and loading requirements, keeping your operations efficient and safe. Ready to elevate your facility’s performance? Explore the perfect dock house solution tailored to your needs today!

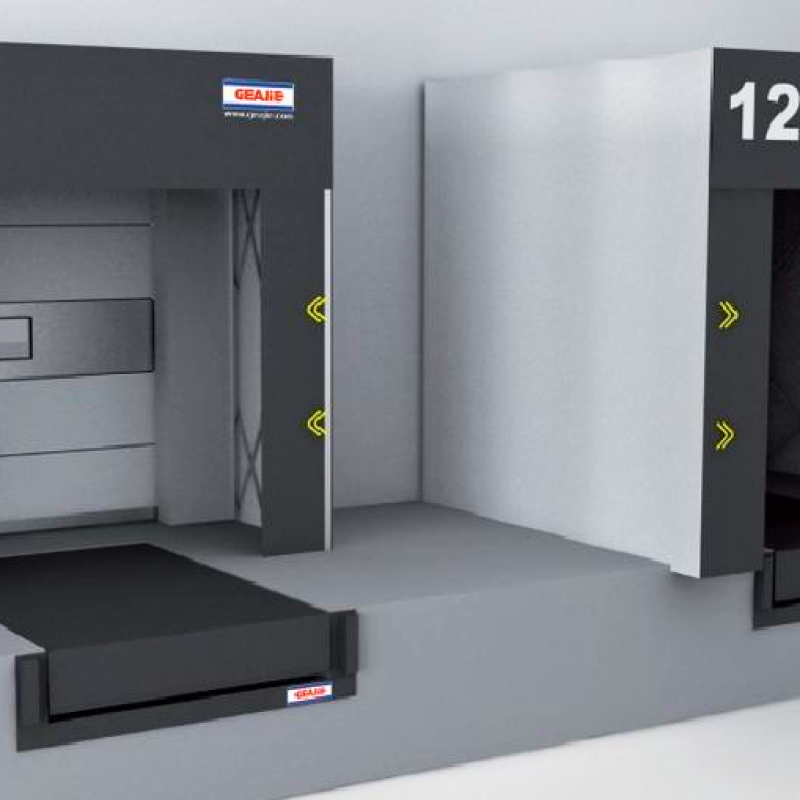

How Loading Dock Houses Work:

Loading dock houses are specially designed structures that extend from your facility, creating a fully enclosed loading and unloading area. They act as a protective barrier between your warehouse and external conditions, ensuring goods are transferred smoothly from truck to facility without exposure to rain, wind, or extreme temperatures. These dock houses are ideal for facilities that handle sensitive products or require a controlled environment to maintain operational efficiency and safety.

Customization Options:

We offer loading dock houses in a variety of sizes, materials, and configurations to suit your specific operational needs. From insulated walls and roofs for temperature-sensitive environments to specialized dock seals for an airtight connection, our solutions can be tailored to meet the unique demands of your facility. Additional options such as integrated lighting, ventilation systems, and custom colors ensure that your loading dock house not only performs optimally but also aligns with your facility’s design and branding.

A loading dock house is an enclosed structure that extends from your facility to the loading dock, providing a secure and weather-protected area for loading and unloading goods. It helps maintain internal temperature control, protects products from external elements, and improves overall operational efficiency and safety.

Yes, our loading dock houses are fully customizable to accommodate various truck sizes and types. We offer adjustable heights, widths, and depths to ensure a perfect fit for your facility’s specific loading and unloading needs.

By creating an enclosed loading area, dock houses minimize air exchange between the inside of your facility and the external environment. This helps maintain a consistent internal temperature, reducing the strain on HVAC systems and lowering energy costs.

Loading dock houses require minimal maintenance. Regular inspections of the seals, doors, and structure for wear and tear, along with periodic cleaning, will help maintain their performance and longevity. Any damaged components should be repaired or replaced promptly to ensure optimal protection.

Yes, loading dock houses can be integrated with your existing dock equipment, such as dock levelers, shelters, and lighting systems. Our designs can be customized to fit seamlessly with your current setup, enhancing the overall efficiency of your loading dock operations.

Absolutely. Loading dock houses can be equipped with insulated walls, doors, and roofs to maintain low temperatures and protect temperature-sensitive goods during loading and unloading. This makes them an ideal solution for cold storage and refrigerated warehouses.

Loading dock houses are built with high-quality, weather-resistant materials such as insulated panels, durable steel frames, and heavy-duty dock seals. These materials are selected to provide maximum durability and protection against harsh environmental conditions.

The installation time for a loading dock house depends on its size and complexity, but it typically ranges from a few days to a couple of weeks. Our team works efficiently to minimize disruptions to your operations and ensure a smooth installation process.

Success Story 1: Improving Operational Efficiency for a Pharmaceutical Distribution Center

Client: Major Pharmaceutical Distributor in South Korea

Challenge: The client needed to ensure strict temperature control and protection against contaminants during loading and unloading operations. Their previous setup left products exposed to external elements, leading to temperature fluctuations and potential contamination risks, especially during extreme weather conditions. This compromised product integrity and required frequent quality checks, slowing down their operations.

Solution: We installed a series of customized loading dock houses with insulated walls, roofs, and airtight dock seals. These dock houses provided a fully enclosed and climate-controlled environment for loading and unloading. The integration of automated doors and ventilation systems further enhanced the protection of temperature-sensitive pharmaceuticals.

Results: The client reported a significant improvement in maintaining the required temperature levels during loading and unloading, reducing the risk of product degradation. Operational efficiency increased by 30%, as the need for additional quality checks and manual handling was minimized. The protected environment also reduced contamination risks, ensuring compliance with stringent industry regulations and improving overall product safety.

Success Story 2: Enhancing Safety and Reducing Costs for an Automotive Parts Manufacturer

Client: Leading Automotive Parts Manufacturer in China

Challenge: The client was experiencing frequent disruptions and safety incidents at their loading docks due to exposure to rain, wind, and dust. The unprotected loading areas led to water accumulation, slippery surfaces, and dust contamination of sensitive parts, causing delays, additional cleaning costs, and safety hazards for employees.

Solution: We installed durable loading dock houses with reinforced weatherproof structures and integrated drainage systems to prevent water buildup. The dock houses were also equipped with high-quality dock seals and LED lighting to ensure a well-lit, clean, and dry loading environment, even during adverse weather conditions.

Results: After the installation, the client saw a 40% reduction in loading and unloading delays and a significant decrease in safety incidents related to wet and slippery surfaces. The enclosed loading dock houses also minimized dust contamination, reducing cleaning costs and protecting sensitive automotive components. Overall, the client experienced a more efficient and safer loading process, leading to increased productivity and reduced operational costs.

Protect your facility and optimize efficiency with our high-quality loading dock houses. Tailored to your specific needs, they provide unmatched protection against weather and external elements, ensuring smooth and safe loading every time. Contact us now to customize the ideal solution for your business!

Suitable for Cold Chain and Loading Dock Renovation: Are you looking for solutions specifically designed for cold chain environments or loading dock renovation projects?

Ideal for Retrofitting Loading Platforms: Do you need a product that is particularly suitable for retrofitting projects involving the addition of loading platforms?

Modular Design for Easy Transportation and Assembly: Are you seeking a modular design that facilitates easy transportation and assembly?

Improved Roof Drainage: Do you require a solution with a roof design that offers better drainage?

Insulated Frame Options: Are you looking for a frame that can be insulated according to your specific requirements?

- The tunnel-type dock shelter provides a convenient long-distance connection between the warehouse and the truck.

- It features a retractable folding design.

- Ensuring windproof and dustproof sealing during loading and unloading operations.

A loading dock house is a specially designed facility to optimize loading and unloading operations in factories and warehouses. It not only maximizes space utilization but also enhances operational efficiency and safety. Here are the main reasons to choose a loading dock house:

Space Savings

As an extension of the warehouse, a loading dock house can minimize the use of internal passageways, freeing up more space for other logistics and storage operations. In facilities with unique layouts, a loading dock house can flexibly meet specific site requirements, optimizing the use of available space.Improved Loading and Unloading Efficiency

The base of the loading dock house is equipped with a loading platform, and the sides and top are constructed with polyurethane sandwich panels, creating an enclosed passageway. This design provides a protected environment, allowing forklifts to easily access and perform loading and unloading tasks, reducing delays caused by external conditions and improving overall efficiency.Excellent Sealing and Insulation

Loading dock houses are equipped with dock seals or shelters, creating a fully enclosed passageway. This design is especially suitable for areas requiring temperature control, such as cold chain logistics and food processing industries. It helps maintain the temperature difference between the inside and outside, reducing energy consumption and preserving the quality of goods.High Adaptability

Loading dock houses can be customized to meet different site conditions and accommodate various loading and unloading needs. Whether adding additional space to a new facility or modifying or expanding an existing one, loading dock houses offer flexible adaptation.Enhanced Working Environment

By providing a dedicated loading area, a loading dock house effectively shields against external weather conditions such as wind, rain, and snow, improving working conditions for employees and enhancing both efficiency and safety.

Choosing a loading dock house provides factories and warehouses with an efficient and safe loading solution, optimizing space utilization, reducing energy consumption, and improving the efficiency of logistics and warehousing operations.

A dock house is a specially designed structure that provides a closed environment for loading and unloading operations between trucks and warehouses, protecting goods from wind, rain, dust, and temperature changes. It is commonly used in warehouses, cold storage facilities, and logistics centers where maintaining a stable indoor environment is crucial. Here are the steps and precautions for using a dock house to ensure safe and efficient operation.

1. Inspect the Dock House Condition

- Before use, check the condition of the dock house to ensure the structural frame, wall panels, and sealing devices are intact and not damaged or worn.

- Ensure the sealing devices (such as door seals and gaskets) are in good condition, with no cracks or damage, to effectively block external elements.

- Check the electrical systems, lighting, and ventilation equipment to ensure all functions are operating correctly.

2. Prepare the Loading Area

- Clear the interior and exterior areas around the dock house of any debris, tools, or equipment that might obstruct operations, keeping the work area clean.

- Ensure the truck is accurately parked in the designated position and use wheel chocks to secure the wheels, preventing vehicle movement during loading or unloading.

3. Align and Dock the Truck

- Slowly guide the truck to back up, aligning it with the entrance of the dock house.

- Once the truck is stationary, ensure the trailer is tightly connected with the dock house’s sealing devices to create a closed passage that prevents external air or contaminants from entering.

4. Open the Dock House and Truck Doors

- After ensuring the truck is correctly docked, open the dock house doors and the truck doors to provide a clear loading path.

- Check that there are no obstacles in the passage to ensure smooth loading and unloading.

5. Perform Loading and Unloading Operations

- Use forklifts or other handling equipment to transfer goods from the truck into the warehouse or load goods from the warehouse into the truck.

- Ensure goods are safely loaded and unloaded during operations, avoiding damage to goods or equipment.

6. Complete Loading and Close the Dock House

- After completing the loading and unloading, close the truck doors and the dock house doors to ensure all goods are properly handled.

- Guide the truck to slowly exit the loading area and check whether the dock house’s sealing devices need adjustment or maintenance.

7. Clean and Maintain

- After use, clean the interior and exterior areas of the dock house, remove all tools and debris, and ensure the area is tidy, preparing for the next use.

- Regularly inspect all components of the dock house, including sealing devices, doors, and frames, to ensure they are not damaged or need repair.

- Regularly maintain electrical systems and ventilation equipment to keep them in good working order.

Precautions

- When using the dock house, wear appropriate protective gear, such as safety shoes and gloves.

- Avoid standing in the loading passage during operations to prevent accidents.

- Ensure all operators are trained and familiar with the equipment’s operation procedures and safety guidelines.

- If any equipment malfunctions or abnormalities are detected, stop using the dock house immediately and contact a professional for repairs.

By following these steps and precautions, you can ensure the safe and effective use of the dock house, enhance loading efficiency, and protect both goods and personnel.