When precision and flexibility are critical, our inflatable dock seals provide the ultimate solution for maintaining energy efficiency and environmental control during loading and unloading. Inflate only when needed, offering a tight, custom fit around various trailer sizes.

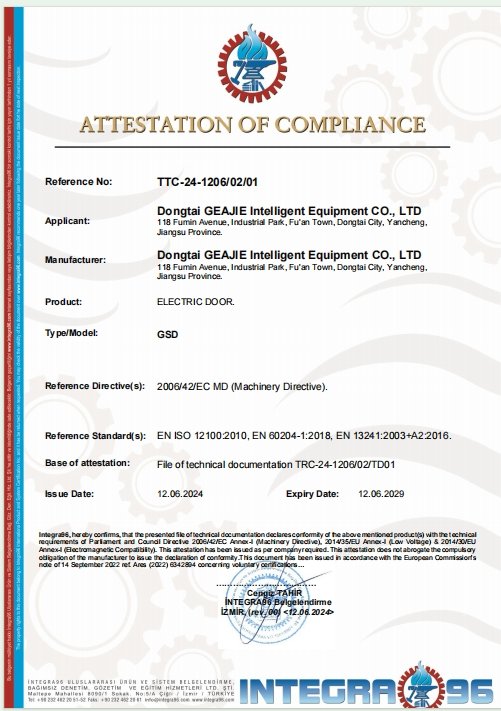

CE Certified: Our stacking doors adhere to European safety and quality regulations, offering you the assurance that they meet rigorous industry standards. Warranty: We provide a [X-year] warranty, ensuring the long-term performance and durability of your doors.

Effortless Protection and Energy Efficiency for Your Loading Dock

Achieve a perfect seal every time with our inflatable dock seals. Designed to inflate and conform tightly around trailers, these seals provide unparalleled protection against external elements, minimizing temperature loss and reducing energy costs. Whether you’re handling small delivery trucks or large transport trailers, our durable and versatile inflatable dock seals ensure a secure fit for any vehicle. Boost your operational efficiency and safeguard your facility with a solution that adapts to your needs.

Detailed Product Information

How Inflatable Dock Seals Work:

Inflatable dock seals use an air-powered system to create a tight, conforming seal around the trailer, effectively blocking out external air, moisture, and contaminants. When the truck is in position, the dock seal inflates, filling any gaps and providing a secure, airtight barrier. This makes them ideal for facilities that require precise environmental control, such as cold storage warehouses and food processing plants. The seals deflate once the truck departs, minimizing wear and tear and allowing for smooth, efficient operations.

Customization Options:

We offer inflatable dock seals in a variety of sizes and designs to meet the unique requirements of your facility. Options include different inflatable chamber shapes for varying dock configurations, heavy-duty materials for high-traffic environments, and custom colors to match your facility’s aesthetics. Additionally, automation features can be integrated to provide seamless control over inflation and deflation, enhancing convenience and ensuring a reliable seal with every use.

Inflatable dock seals provide a tighter, more adaptable fit than foam seals. Foam seals rely on compression to form a barrier, while inflatable seals inflate to conform precisely to the shape of the trailer, offering superior protection and energy efficiency.

With proper maintenance, inflatable dock seals can last for several years. They typically experience less wear and tear compared to other types of dock seals, as they only inflate when in use, minimizing constant exposure to elements.

Yes, our inflatable dock seals are built to withstand extreme temperatures, from freezing cold to intense heat, and they provide year-round protection against rain, snow, and dust.

Absolutely. Inflatable dock seals are designed to conform to a wide range of truck sizes and shapes. We offer custom sizes and configurations to ensure a perfect fit, providing an effective seal regardless of the vehicle type or dock height.

By creating a precise, airtight seal, inflatable dock seals prevent temperature loss during loading and unloading. This reduces the load on your HVAC systems, resulting in lower energy consumption and decreased utility costs, especially for temperature-sensitive facilities like cold storage or food processing.

No, inflatable dock seals are relatively easy to install. They come with a comprehensive installation guide, and our team is available to provide support as needed. Once installed, they integrate seamlessly with your existing dock system, offering immediate benefits.

Maintenance for inflatable dock seals is minimal. Regular inspections for air leaks, proper inflation, and general condition are recommended. Ensuring the air pump and control systems are functioning correctly will help maintain the seals’ performance and longevity.

Yes, our inflatable dock seals are equipped with safety features such as pressure relief valves to prevent over-inflation and emergency deflation mechanisms for quick release if needed. These features ensure safe and efficient operation, even in high-traffic environments.

Success Story 1: Enhancing Temperature Control for a Cold Storage Facility

Client: Major Cold Storage Logistics Company in Vietnam

Challenge: The client faced significant challenges in maintaining stable temperatures during loading and unloading operations. Traditional foam dock seals were not providing an effective seal, resulting in temperature fluctuations that jeopardized the quality of temperature-sensitive goods. Additionally, the energy costs to maintain the desired cold storage temperatures were becoming unsustainable.

Solution: We recommended and installed inflatable dock seals, specifically designed to create a tight, adaptable seal around the trailers. These seals inflate to conform precisely to the shape of each truck, eliminating gaps and significantly reducing air exchange between the dock and the external environment. The seals were also equipped with automated inflation and deflation controls to ensure quick and efficient operations.

Results: After implementing the inflatable dock seals, the client observed a dramatic improvement in temperature stability during loading and unloading, with internal temperatures remaining within the required range. This not only enhanced product safety and quality but also led to a 25% reduction in energy consumption, as the facility’s HVAC systems no longer had to compensate for temperature loss. The improved sealing also reduced the risk of contamination, contributing to overall operational efficiency and safety.

Success Story 2: Boosting Efficiency and Reducing Downtime for an Automotive Manufacturer

Client: Leading Automotive Manufacturer in South Korea

Challenge: The client was experiencing delays and inefficiencies during their loading and unloading processes due to inadequate sealing solutions. The foam dock seals previously used did not accommodate the wide variety of truck sizes, leading to frequent air leaks, debris intrusion, and increased downtime for cleaning and adjustments. This not only slowed down their operations but also resulted in higher energy costs and disrupted production schedules.

Solution: We provided custom inflatable dock seals that could adapt to different truck sizes and shapes, ensuring a consistent and airtight seal for every vehicle. The seals were constructed from heavy-duty, puncture-resistant materials to withstand the high-traffic environment and integrated with automated controls for quick inflation and deflation. This allowed for seamless docking without the need for manual adjustments.

Results: The installation of the inflatable dock seals resulted in a significant reduction in loading and unloading times, with a 30% improvement in overall operational efficiency. The airtight seal prevented debris and dust from entering the facility, reducing the need for frequent cleanups and minimizing the risk of damage to sensitive automotive components. The client also reported a 15% decrease in energy costs, as the improved sealing helped maintain a consistent internal environment. The reduction in downtime and increased efficiency enabled the client to meet production targets more effectively, improving their overall competitiveness in the market.

Highest Sealing Performance: Are you looking for a sealing solution that offers the highest level of sealing performance?

Compatibility with the Widest Range of Vehicle Types: Do you need a product that is compatible with the widest range of vehicle types?

- Suitable for the widest range of transport vehicle sizes without applying pressure to the building walls.

- Easy to operate with one-button start, enabling the blower to inflate and deflate the airbags.

- The high-power blower completes the inflation and sealing process within 20 seconds.

- The surface of the dock seal is made of high-quality neoprene rubber, which offers high wear resistance and flexibility, ensuring a lifespan of no less than 30,000 cycles.

Inflatable dock seals are a highly effective sealing solution designed specifically for loading docks, particularly suited for environments requiring strict temperature control and protection. They are adaptable to various vehicle sizes and provide continuous sealing and protection throughout the entire loading and unloading process. Here are the main reasons to choose inflatable dock seals:

Excellent Sealing Performance

Inflatable dock seals work by inflating air bags around the vehicle during loading and unloading, creating a tight seal. This design effectively prevents wind, rain, and temperature fluctuations from affecting the internal environment, maintaining stability, and making them ideal for low-temperature transport needs such as cold chain logistics and the food industry.Adaptability to Various Vehicle Sizes

Inflatable dock seals are flexible and can adjust to fit different vehicle heights and sizes, providing a good seal for everything from low-profile to high-profile vehicles. The air bags automatically adjust with the vertical movement of the vehicle, ensuring consistent sealing and protection throughout the loading and unloading process.Enhanced Protection and Safety

When not in use, inflatable dock seals retract behind the side structure, providing a wider loading area for vehicles and reducing the risk of collisions and damage. Additionally, the seals are equipped with protective devices to prevent damage when used on slopes and uneven surfaces.Durable Materials and Structural Design

The air bags of the dock seals are made from impact-resistant materials with a durable fabric core, offering weather resistance and flame retardant properties. The high durability of the materials ensures safe, long-term use in harsh environments, making them ideal for frequent loading and unloading operations.Energy Efficiency and Insulation

Inflatable dock seals are installed within a frame covered by insulation panels, which enhances their insulating properties and helps reduce energy consumption. This design helps maintain stable temperatures inside the warehouse, minimizing heat loss.Easy Maintenance and Component Replacement

The design simplicity of inflatable dock seals allows for easy maintenance and quick replacement of components, reducing downtime and maintenance costs, and ensuring efficient and continuous loading and unloading operations.

Choosing inflatable dock seals provides strong sealing and protection for loading docks, saves energy, improves operational efficiency, and is an ideal solution for optimizing warehouse and logistics facilities.

An inflatable dock seal is a highly effective sealing device commonly used in loading areas of warehouses, cold storage facilities, and logistics centers. It uses inflatable technology to expand and tightly seal around the perimeter of a truck when docked, providing excellent protection against external dust, rain, and cold air. Inflatable dock seals are particularly suitable for environments that require high levels of sealing performance. Here are the steps and precautions for using an inflatable dock seal to ensure safe and effective operation.

1. Inspect the Equipment Condition

- Before use, check the condition of the inflatable dock seal to ensure that the airbags, frame, and support structures are free from damage or significant wear.

- Ensure that all airbags are free of leaks, and that air hoses are securely connected without cracks or leakage.

- Check all fastening devices and components to ensure they are securely attached, and that all control devices are functioning properly.

2. Prepare the Loading Area

- Clear the area around the dock seal, removing any items that could obstruct its operation, such as debris, tools, or equipment.

- Ensure the truck is correctly positioned in the designated loading area and use wheel chocks to secure the wheels, preventing the vehicle from moving during loading or unloading.

3. Align and Park the Truck

- Guide the truck to back up slowly, aligning it with the inflatable dock seal.

- Once the truck is properly parked, ensure there is sufficient distance between the trailer and the dock seal to allow the airbags to expand and form a tight seal.

4. Activate the Inflation System

- Start the dock seal control system and turn on the air pump to begin inflating the airbags.

- Monitor the inflation process, ensuring the airbags fully expand to make tight contact with the trailer sides, achieving optimal sealing.

5. Perform Loading and Unloading Operations

- After the airbags are fully inflated and a tight seal is achieved, open the truck doors and proceed with loading or unloading goods.

- Ensure goods are loaded and unloaded safely, avoiding any damage to the dock seal.

6. Complete Loading and Retract the Equipment

- After loading or unloading, close the truck doors and stop the inflation process, then activate the deflation function to release the air from the airbags.

- Wait for the airbags to fully deflate and return to their original position before guiding the truck to slowly leave the loading area.

7. Maintenance and Cleaning

- After use, check the inflatable dock seal for any damage or wear.

- Regularly clean the airbags and frame to remove dust and debris, maintaining effective sealing performance.

- Regularly inspect the airbags, air hoses, and other components to ensure they are in good working condition and perform necessary maintenance as needed.

Precautions

- When using the dock seal and loading goods, wear appropriate protective gear such as gloves and safety shoes.

- Avoid guiding the truck too quickly to prevent impact damage to the dock seal.

- Ensure all operators are familiar with the correct usage procedures and safety precautions.

- If any abnormalities or damage are found during use, stop using the dock seal immediately and contact a professional technician for inspection and repair.

By following these steps and precautions, you can ensure the safe use of the inflatable dock seal, improve loading efficiency, and extend the equipment’s service life.