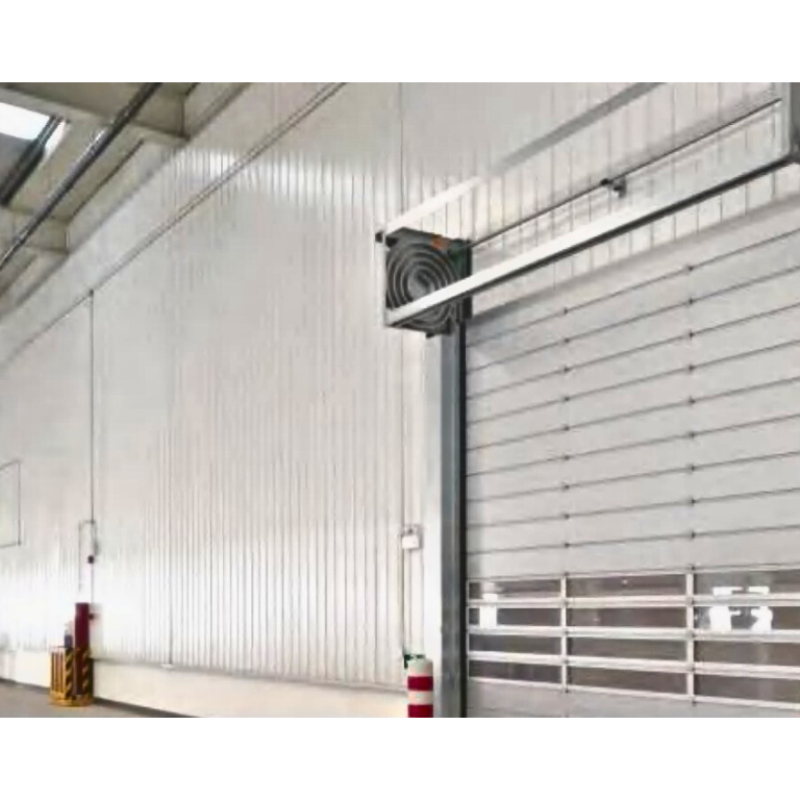

How Hard Fast Doors Work: Hard fast doors feature a rigid panel design made from durable materials such as reinforced steel or aluminum. These doors operate at high speeds, improving productivity and maintaining security while reducing the risk of damage from impacts. Their robust construction ensures reliable performance in high-traffic industrial environments.

Customization Options: We offer a variety of sizes, materials, and finishes to match your facility’s specific needs. Options include insulated panels for temperature control and advanced security features for high-risk areas.

Maximize Security and Efficiency with Cutting-Edge Design

When it comes to fast-paced industrial environments, time is money. Our rigid high-speed doors are engineered to provide both speed and durability, keeping your workflow uninterrupted while offering top-notch security. Ideal for demanding applications, these doors withstand harsh conditions while reducing energy loss and maintenance costs. If you’re looking for a reliable, high-performance solution to streamline your operations, our rigid fast doors are the perfect fit. Discover how you can boost productivity without compromising on quality or safety.

What industries are hard fast doors suitable for?

Hard fast doors are ideal for industries such as logistics, manufacturing, cold storage, and security-sensitive environments where speed, security, and durability are essential.

How do these doors enhance security?

The rigid construction of hard fast doors provides superior resistance to forced entry, ensuring that your facility remains secure at all times.

Are these doors weather-resistant?

Yes, hard fast doors are designed to withstand extreme weather conditions, including high winds, rain, and fluctuating temperatures, making them suitable for both indoor and outdoor use.

Can these doors help with energy efficiency?

Absolutely. The fast operation and tight seals of hard fast doors minimize air exchange, helping maintain internal temperatures and reducing energy costs in climate-controlled environments.

Are automation options available?

Yes, we offer fully automated hard fast doors with options for remote control, sensor-based operation, and smart integration for seamless use.

How easy is maintenance?

Hard fast doors are designed for low maintenance, with durable materials and reliable mechanics that reduce the need for frequent repairs. Routine inspections and cleaning are usually sufficient.

What is the delivery time for standard models?

Standard models are typically in stock and can be delivered within [X days]. Custom orders may require additional time based on your specifications.

How long is the warranty?

We provide a [X-year] warranty to ensure that your hard fast doors perform reliably under heavy-duty conditions.

Success Story 1: Streamlining Operations for a Global Logistics Company

Client: A leading logistics provider with multiple international distribution centers

Challenge: Frequent delays due to slow, inefficient doors, compromising security and temperature control

Solution: Installation of GEAJIE rigid fast doors in their main distribution hub

Outcome:

The company was facing significant operational inefficiencies caused by outdated sectional doors that were slow to open and close, leading to workflow bottlenecks and temperature inconsistencies. After switching to GEAJIE’s rigid fast doors, the distribution center saw a marked improvement in operations. Door opening and closing times were cut by 40%, resulting in smoother and faster loading and unloading processes. Additionally, the doors’ robust construction enhanced security, while the tight seals minimized energy loss, reducing utility costs by 15%. The client was highly satisfied with the quick return on investment, especially during peak shipping seasons.

Success Story 2: Enhancing Security and Efficiency for a Food Processing Plant

Client: A large-scale food processing facility

Challenge: Maintaining strict hygiene and temperature control while ensuring security in a high-traffic area

Solution: Installation of GEAJIE rigid fast doors in multiple high-traffic zones

Outcome:

The facility required doors that could open and close quickly to maintain strict hygiene standards while preventing temperature fluctuations in cold storage areas. Their previous doors struggled to meet these demands, resulting in temperature control issues and increased energy costs. GEAJIE’s rigid fast doors provided the perfect solution, ensuring rapid, reliable access for workers and equipment while maintaining a secure and controlled environment. After installation, the facility reported a 25% reduction in energy costs and a significant improvement in maintaining consistent temperatures, which was crucial for food quality. Additionally, the enhanced security features provided peace of mind for management, knowing that sensitive areas were well protected.

High-Speed Opening and Stable Operation: Are you looking for doors that open quickly and operate smoothly, with high sealing, insulation, and wind resistance capabilities?

Resistance to Harsh Weather Conditions: Do you need doors that can effectively resist the impact of harsh weather and prevent indoor and outdoor air exchange?

Ideal for Frequent Access Passages: Are you seeking a solution that is ideal for frequent access areas, serving as an alternative to sectional doors and PVC fast doors?

Energy Efficiency and Cost Reduction: Are you interested in doors that are a top choice for industrial energy saving and cost reduction?

Suitable for High-Demand Environments: Do you require doors specifically designed for high-precision manufacturing, food processing, electronics, pharmaceuticals, or other environments with high sealing requirements and frequent access?

- Special turbine track design ensures that the door curtain does not make contact during high-speed opening.

- The door panels feature a cold bridge design with polyurethane insulation, providing thermal insulation and wind resistance.

- Dual-purpose design: can replace the combination of an insulated sectional door and a high-speed door.

- The door is equipped with a spring-balanced design, allowing for easy manual opening in case of emergencies.

Hard turbo fast doors, also known as aluminum alloy fast doors or hard fast doors, are an advanced type of metal rapid door suitable for a range of industrial and commercial settings. They offer a combination of anti-theft features, high-speed operation, and high-temperature resistance, providing both practicality and reliability. Here are the key reasons to choose hard turbo fast doors:

Combines High Speed and Insulation

Hard turbo fast doors bring together the benefits of high-speed doors and industrial overhead doors, offering rapid opening and closing speeds (up to 3 meters per second) along with excellent insulation and sealing capabilities. This makes them perfect for environments requiring efficient access and strict temperature regulation, such as cold storage facilities, food processing plants, and electronics manufacturing areas.Durable Construction and Modern Design

These doors are made from high-strength industrial aluminum alloy, which ensures a long service life and a sleek, modern appearance. The door frames, made from galvanized or cold-rolled steel with an electrostatic powder coating, are designed to be both durable and aesthetically pleasing, enhancing the visual appeal of any facility.Versatile Control and Safety Features

Hard turbo fast doors provide a variety of control options, including standard button controls, radar sensors, ground magnetic sensors, manual pull ropes, and remote control options, offering flexibility to suit different environments. They also include a comprehensive set of safety features, such as built-in safety fuses, safety switches, automatic safety edges, and safety photo eyes, to ensure safe operation. Additionally, a manual emergency release function allows the doors to be quickly opened during emergencies.Superior Wind Resistance and Sealing

These doors are designed to withstand high winds, with resistance up to 12 meters per second, making them ideal for use in outdoor or high-wind environments. The track sealing and door curtain connection sealing systems effectively prevent dust, pollutants, and air leakage, ensuring a clean and stable indoor environment.Broad Range of Applications

Hard turbo fast doors are suitable for a wide array of applications, including underground parking garages, automotive manufacturing facilities, food and chemical processing plants, textile factories, electronics production lines, supermarkets, logistics centers, warehouses, and cold storage units. They are particularly effective in settings that demand frequent door operation and high standards of insulation and dust control, significantly improving efficiency and safety.Energy Efficiency and Optimized Operation

The fast opening and closing capabilities of hard turbo fast doors minimize energy loss and temperature fluctuations, while their compact design conserves space. This makes them especially effective in high-traffic areas such as logistics hubs and production floors, enhancing overall operational efficiency.

Choosing hard turbo fast doors offers a highly efficient, safe, and durable solution for a variety of industrial and commercial needs, meeting the demands of modern facilities looking to optimize performance and security.

Hard high-speed doors, also known as aluminum alloy high-speed doors, are widely used in industrial and commercial environments. They are especially suitable for areas requiring frequent entry and exit, high insulation, and quick operation, such as cold storage, garages, logistics centers, and production workshops. These doors are durable and provide excellent safety and efficiency under high-frequency use. Here are the steps and precautions for operating a hard high-speed door correctly to ensure safe and efficient use.

1. Inspect the Door Condition

- Before using, check the overall condition of the hard high-speed door to ensure the door panels are free of cracks, deformation, or other damage.

- Inspect the tracks, guide devices, and hinges to ensure they are not worn or loose, and all components are functioning properly.

- Verify that all safety devices, such as photoelectric sensors, emergency stop buttons, and safety edges, are working correctly, and all control buttons and indicator lights are operational.

2. Prepare the Operating Area

- Clear the area around the door, removing any items that might obstruct the door’s movement, such as stacked goods, tools, or equipment.

- Ensure there are no people or obstacles in the door’s path to avoid accidents during operation.

3. Activate the Control System

- Ensure the power supply is connected and activate the door’s control system.

- Use the “Up” or “Down” buttons on the control panel to operate the door’s opening and closing, and check all indicator lights to confirm the equipment is functioning properly.

4. Operate the Door

- Press the “Up” button to slowly raise the door to the desired height, ensuring smooth movement along the tracks without sticking or abnormal motion.

- When the door is fully open, ensure it remains in a safe position to prevent accidental closing.

- To close the door, press the “Down” button and slowly lower it to the fully closed position, ensuring there are no obstructions in the door’s path.

5. Ensure the Door is Securely Locked

- After closing the door, check if the safety edges and locking mechanisms have properly engaged to prevent accidental opening when unattended.

- Confirm that the door is securely locked and check that the lock status indicator light is normal.

6. Perform Regular Inspections and Maintenance

- Regularly inspect all parts of the door, including the panels, tracks, guide devices, and seals, to ensure there is no damage or wear.

- Lubricate the tracks and moving parts to maintain smooth operation, and check all fasteners and bolts to ensure they are not loose.

- Periodically test all safety devices, such as photoelectric sensors and emergency stop buttons, to ensure they function properly when needed.

7. Shut Down the System and Clean the Area

- After use, shut down the control system and disconnect the power supply to ensure the equipment is completely turned off, preventing accidental activation.

- Clean the operating area, removing all tools and obstacles, keeping the area tidy, and preparing it for the next use.

Precautions

- Always wear appropriate personal protective equipment, such as safety shoes and gloves, when operating the door.

- Avoid overloading the door or placing excessive weight on it to prevent damage to the structure or mechanical components.

- Ensure all operators are trained and familiar with the door’s operating procedures and safety guidelines.

- If any abnormalities are observed during operation, such as unusual noises or difficulty in operation, stop using the door immediately and contact a professional technician for inspection and repair.

Following these steps and precautions when operating a hard high-speed door will ensure safe use, extend its service life, and improve work efficiency.

Geajie has a history of 11 years. It started as a small workshop and gained recognition for its excellent quality. Through word of mouth, more and more buyers came to us, and Geajie eventually grew into a large factory known for its reliable quality. Click the button below to get in touch with us, and we will customize a factory solution for you.

Geajie hard high-speed doors offer excellent sealing, insulation, and wind resistance, effectively withstanding harsh weather conditions. They can prevent indoor and outdoor air exchange, making them ideal for frequently used passages. These doors combine the features of both sectional doors and PVC high-speed doors. GEAJIE’s Hard Turbo Rapid Door is an indispensable, high-efficiency solution in various industrial environments.

- Combines insulation, energy efficiency, sealing, high performance, wind resistance, and environmental friendliness to provide comprehensive performance.

- Features a turbo track design, double-layer aluminum panels, and polyurethane filling for exceptional thermal insulation and wind resistance.

- Ideal for high-frequency, high-speed logistics channels, effectively replacing insulated sectional doors.

- Saves up to 80% energy, with an adjustable speed range from 0.6 to 1.2 meters per second.

- Equipped with a spring balance system, allowing manual operation in emergencies to ensure safety.

- A stable and reliable system that guarantees over 150,000 trouble-free cycles annually.

Don’t wait to invest in a Geajie rigid high-speed door—buy it now and experience the difference. With its superior safety features, unmatched durability, and energy efficiency, this door will not only protect your facility but also enhance your operations. Secure your investment today, and enjoy the peace of mind and long-term benefits that come with choosing Geajie. Don’t just wait to buy—buy now and reap the rewards for years to come!

we give the best

We give the best, ensuring top-notch quality, unmatched reliability, and exceptional service with every product we deliver.

friendly price

We offer a friendly price, giving you exceptional value without compromising on quality or performance.

Work wholeheartedly

friendly service

We provide friendly service, always prioritizing your needs and ensuring a positive experience at every interaction, from the first inquiry to after-sales support.

- The turbo hard rapid door utilizes a specialized control system with a DSP processing chip at its core. The system accurately controls the door’s opening height by receiving encoder signals:

- Direction protection: If the motor drive line is connected incorrectly, the controller directly reports an error, and the door stops moving.

- The dedicated system features full closed-loop control for torque, position, and speed.

- The system includes a built-in braking function, allowing the motor to stop at the specified position without the need for external electromagnetic brake pads, ensuring the door stops precisely at the limit position.

- Memory function after power failure: After manual operation during a power outage, the system can resume work immediately upon power restoration without needing further adjustment.

- Motor overload and overcurrent protection.

The motor drive system uses a servo motor system, which includes a branded encoder, braking system, and emergency manual opening mechanism: The servo motor’s constant torque output maximizes the effectiveness of safety protection devices (such as infrared sensors), enabling quick rebound. It has strong overload capacity, capable of operating more than a thousand times a day in high-frequency environments.

- The constant torque characteristic of the servo motor ensures smoother operation of the door and effectively addresses noise issues during movement. The end cushioning technology provides effective protection against rigid damage to the gearbox and operating mechanism. The system allows for digital adjustment of different speeds according to actual needs, with full-length variations from fast to slow to stop. This reduces wear on various components, with particular emphasis on protecting the gearbox.

- The aluminum alloy turbine-guided bearing track of this door is our company’s patented technology, ensuring high-speed operation of the door curtain during opening and closing. The rotational friction between the door curtain and the track effectively controls noise. Depending on the installation structure on site, the track can be configured as turbine suction, elliptical suction, vertical lift, 90-degree standard corner lift, or other track styles. The standard configuration is turbine suction, and other lifting methods require prior arrangement with our sales team.

- The door curtain is composed of a segmented assembly structure, including thermally insulated aluminum alloy panels, noise-reducing load-bearing hinges, and polyurethane guide wheels. The standard thickness of the insulated door panels is 40mm. The surface undergoes anodizing and organic coloring treatment, with wind resistance up to Level 12 according to international color chart standards. Available color options include gold, blue, silver, gray, white, and China red, among others. The load-bearing hinge design ensures that the joints between the door panels do not bear stress, and the panels do not touch each other, maintaining flatness even over long periods. During operation, the door moves smoothly as the polyurethane guide wheels slide within the aluminum alloy tracks, ensuring stable performance even at high speeds.

-

Infrared Safety Protection Sensors: Photoelectric sensors are installed on both sides of the door frame. When there is an obstacle beneath the high-speed door, the door remains in the open position. If the door is descending and an object passes through, the door will reopen to the fully open position and then delay descending until the obstacle is cleared. An external infrared device can be used to control the quick rebound of the door. The rebound speed can be easily set by adjusting the parameters. Additionally, the functionality of the infrared device can be defined through parameter changes, such as determining whether the infrared sensor triggers a single rebound or keeps the door stationary for an extended period.

-

Bottom Safety Edge Protection: If the door is descending and an object is in the blind spot of the infrared safety protection, the door will quickly rebound to the fully open position when it encounters an obstacle below. This feature effectively protects objects or pedestrians beneath the door, helping to prevent accidents.

| Feature | Description |

|---|

| Wind Resistance | Wind resistance of 32 m/s (complies with the national standard wind resistance level 12). |

| Transparent Window | High-quality polycarbonate panel with a double-layer design ensures thermal insulation while maintaining excellent transparency and lighting. |

| Sealing Performance | Multiple seals including track seals, middle door panel seals, top door seals, and bottom door seals ensure airtightness and isolation between the interior and exterior of the door. |

| Thermal Insulation | For an installed door in the closed state (4x3m), thermal insulation performance K ≤ 0.6W/(㎡•K). |

| Quick Repair | In case of damage to the door panel, there is no need to dismantle the entire door. The suspended insulated aluminum alloy door panel strips can be removed individually, allowing one person to complete the repair quickly and easily. |

| Manual Operation | In the event of a power failure, the motor brake can be released at any time, and the door can be lifted using the balance system, effectively solving the problem of door inoperability due to power outage or malfunction. |

| Balance System | 6 high-strength balance springs inside the columns maintain a balance with the weight of the door panels, reducing the load on the motor during operation, ensuring smooth and effortless movement. |

| Overall Appearance | The precision-formed turbine system, track system, and protective cover are made of Baosteel galvanized plates, cut with laser and CNC bent, ensuring long-lasting rust resistance, aesthetic appearance, dust protection, and easy cleaning. |

| Drive System | The integrated drive system ensures even force distribution on both sides of the door, resulting in smooth overall operation. |

| Control Box | Thickened IP54 control box meets national electrical safety standards. |

| Door Panel Traction | High-quality wear-resistant, high-strength roller chain structure drives the door panel through a synchronous chain into a fast-gear-changing turbine mechanism. |

| Lifting Mechanism | Independently developed aluminum alloy guide rail system meets the requirements for fast speed changes, effectively lifting the door while preventing vibrations and noise. |

| Power Requirements | 220V/14A/50Hz. |

| Insulation Protection | IP54 protection ensures the door is waterproof and dustproof even in harsh environments. |

| Opening Methods | Standard one-button operation with emergency stop switch; optional methods include three-key button, remote control, geomagnetic, radar, pull cord, etc. |

| Size Range | Width: 1250-8000mm Height: 2000-8000mm |

| Opening/Closing Speed | Opening speed: 1.2-2.0 m/s, Closing speed: 0.8 m/s |

| Door Panel | 43mm/80mm polyurethane door panel |

| Door Panel Color | RAL9002, RAL9016, RAL5005 |

| Vision Panel | Standard with 2 rows of vision panels |

| Safety Devices | Standard photoelectric sensor, optional light curtain, safety bottom edge |

| Motor and Gearbox | Servo motor, 220V/380V, 0.55-1.5kw. Other brands are available. |