Maximize Airflow and Energy Efficiency with Our Industrial Ceiling Fan

Ventilation and Cooling Efficiency: Are you looking for an industrial ceiling fan that provides optimal ventilation and cooling? Key factors include motor type (capacitor or split type), and fan blade length and material, which affect coverage area and lifespan. Capacitor-type motors and long, lightweight metal blades are recommended for better efficiency and airflow.

Energy Consumption: Do you prioritize low energy consumption to maximize cost efficiency? The lower the power consumption, the higher the cost-effectiveness for the customer, making energy consumption a crucial factor when selecting a large ceiling fan.

Heat Dissipation: Are you concerned about maintaining a good natural environment in a factory workshop and ensuring effective equipment operation? This requires fans with excellent heat dissipation and ventilation performance, which should be carefully designed and enhanced.

Manufacturer Selection: Do you consider the reputation and reliability of the manufacturer when choosing an industrial ceiling fan? Larger manufacturers often offer better quality and cost advantages due to their manufacturing and volume analysis capabilities. Newer manufacturers may provide more innovative designs, while established ones guarantee product quality and longevity.

Material and Maintenance: Are material safety and ease of maintenance important to you? The safety, material quality, and lifespan of the fan directly affect its performance. Fans made from high-quality materials with professional craftsmanship are preferred to ensure durability and value.

- Simple operation, adjustable speed, forward and reverse rotation control

- Diameters range from 8' to 24' (2.4m-7.3m)

- Airflow up to 400,000 cubic feet per minute

- Variable frequency drive provides soft start and full variable speed operation

- Creates a non-disruptive airflow

- Exclusive positive 5° angle air diffusion technology

Industrial ceiling fans are an economical and efficient cooling and ventilation solution, especially suitable for large factories and open spaces. Compared to central air conditioning and traditional fans, industrial ceiling fans offer several distinct advantages. Here are the main reasons to choose industrial ceiling fans:

Wide Cooling Coverage

A single industrial ceiling fan with a diameter of 7.3 meters can cover an area of 1500-2000 square meters and deliver an airflow of up to 13,600 cubic meters per minute. In a large area, only a few ceiling fans are needed to achieve effective ventilation and cooling. Unlike traditional ventilation equipment, industrial ceiling fans are easier to install and offer better cooling performance.Effective Cooling Performance

Industrial ceiling fans can quickly lower the perceived temperature by 4-6°C, significantly enhancing the comfort of the working environment and providing a more comfortable workspace for employees. While central air conditioning offers a more pronounced cooling effect, its high initial investment and operating costs often deter businesses. Industrial ceiling fans, on the other hand, provide a cost-effective cooling solution without compromising on performance.Cost-Effective Operation

When considering total installation and operational costs, central air conditioning is very expensive. In contrast, industrial ceiling fans are easier and less costly to install and maintain. Although the price of a single industrial ceiling fan may be higher, its long-term operating costs are significantly lower than those of central air conditioning, making it a more economical cooling solution.Easy Installation and Maintenance

Industrial ceiling fans are quick and easy to install, requiring no complex drilling or ductwork, making them suitable for various factory environments. They also require less maintenance compared to traditional fans and air conditioning systems, saving time and reducing maintenance expenses for businesses.Energy Efficiency and Environmental Friendliness

Designed for low energy consumption, industrial ceiling fans use far less electricity than central air conditioning during operation. This not only saves energy costs for businesses but also reduces carbon emissions, making them a more environmentally friendly cooling option.

Choosing industrial ceiling fans not only provides effective ventilation and cooling for large spaces but also significantly reduces operating costs, improves energy efficiency, and creates a more comfortable working environment. These advantages make industrial ceiling fans an ideal choice for large factories and open spaces.

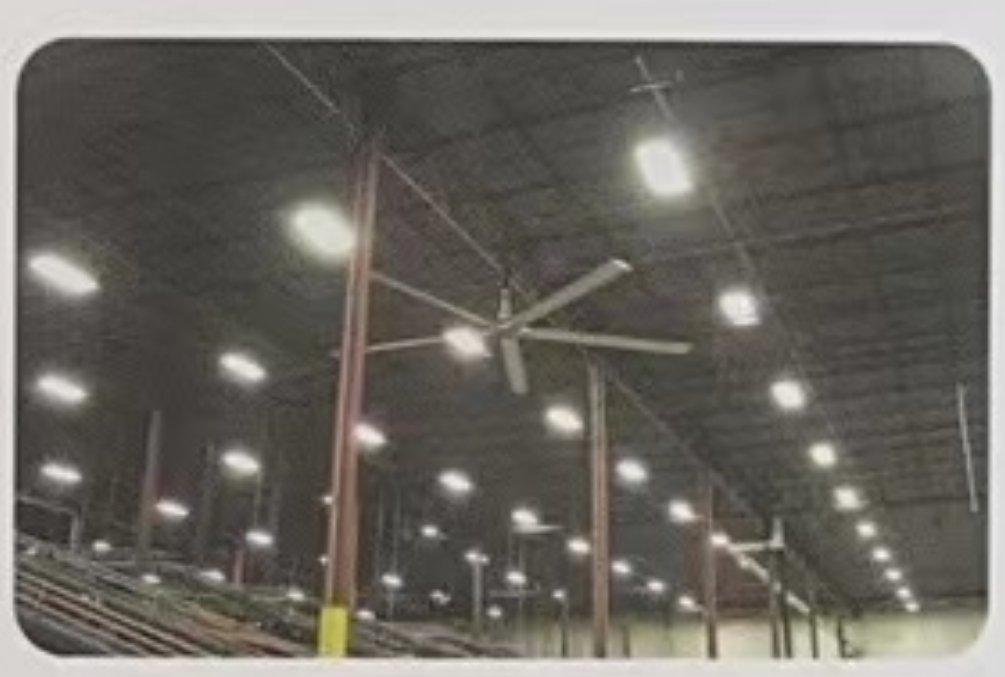

Industrial ceiling fans are widely used in large spaces such as factories, warehouses, gymnasiums, and shopping centers to improve air circulation, enhance ventilation efficiency, reduce temperatures, and create a more comfortable working environment. Below are detailed steps and precautions for using an industrial ceiling fan to ensure safe operation and optimal performance.

1. Pre-Installation Inspection

- Before installation, inspect all parts of the ceiling fan, including blades, motor, mounting brackets, and control systems, to ensure there is no damage or defect.

- Check that the power cables, switches, and control panels are in good condition and free of any damage or malfunction.

- Confirm that the installation area has sufficient ceiling height and structural strength to support the fan’s weight and dynamic load during operation.

2. Installation Steps

- Follow the manufacturer’s instructions to securely mount the ceiling fan to the ceiling, ensuring a firm and stable installation.

- Use appropriate bolts and support structures to keep the fan stable during operation.

- Connect the power supply and control system, ensuring all electrical connections comply with local regulations and standards.

3. Pre-Operation Check

- Before starting the fan, check all fasteners and connections to ensure the fan is securely mounted with no loose components.

- Test the control panel and remote control to ensure they are functioning properly, and check if the emergency stop function is operational.

- Ensure there are no obstacles around the fan to prevent collisions during operation.

4. Starting and Operating the Fan

- Turn on the power and use the control panel or remote control to start the ceiling fan.

- Adjust the fan speed as needed to optimize air circulation and cooling effect.

- Use the timer function (if available) to set the fan’s operating time, ensuring it shuts off automatically when not needed.

5. Operational Precautions

- Avoid conducting any activities directly beneath the fan that could interfere with its operation while it is running.

- Monitor the fan’s operation to ensure there are no unusual noises or vibrations; address any issues immediately.

- Use the emergency stop button on the control panel if an immediate shutdown is necessary.

6. Stopping and Shutting Down the Fan

- When you need to stop the fan, use the control panel or remote to turn it off.

- Turn off the power switch to ensure the fan does not start unexpectedly.

- Wait until the blades have completely stopped spinning before performing any further actions.

7. Regular Maintenance and Upkeep

- Regularly clean the fan blades and motor housing to prevent dust buildup that could affect performance.

- Inspect all fasteners and electrical connections to ensure they are tight and free from damage.

- Lubricate key components, such as bearings and the motor, to ensure smooth operation.

8. Safety Tips

- Ensure all operators are familiar with the fan’s use and safety guidelines.

- Always disconnect the power supply before performing any maintenance or repairs to ensure safety.

- If any malfunctions or abnormalities are detected, stop using the fan immediately and contact a professional technician for repairs.

By following these steps and precautions, you can ensure the safe use and efficient operation of an industrial ceiling fan, providing better air circulation and comfort in your working environment.

Technical Specifications

- Simple operation, adjustable speed, forward and reverse rotation control

- Diameters range from 8' to 24' (2.4m-7.3m)

- Airflow up to 400,000 cubic feet per minute

- Variable frequency drive provides soft start and full variable speed operation

- Creates a non-disruptive airflow

- Exclusive positive 5° angle air diffusion technology

Key Advantages

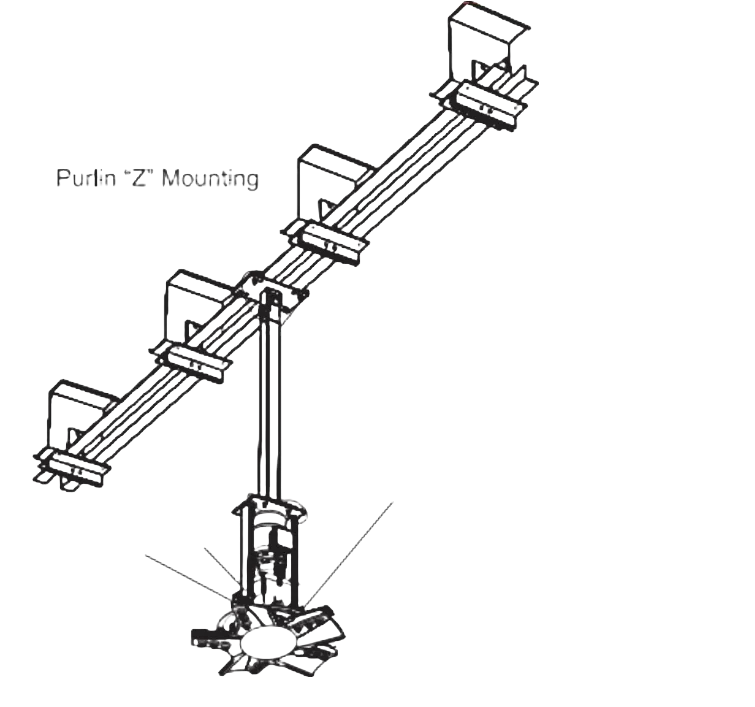

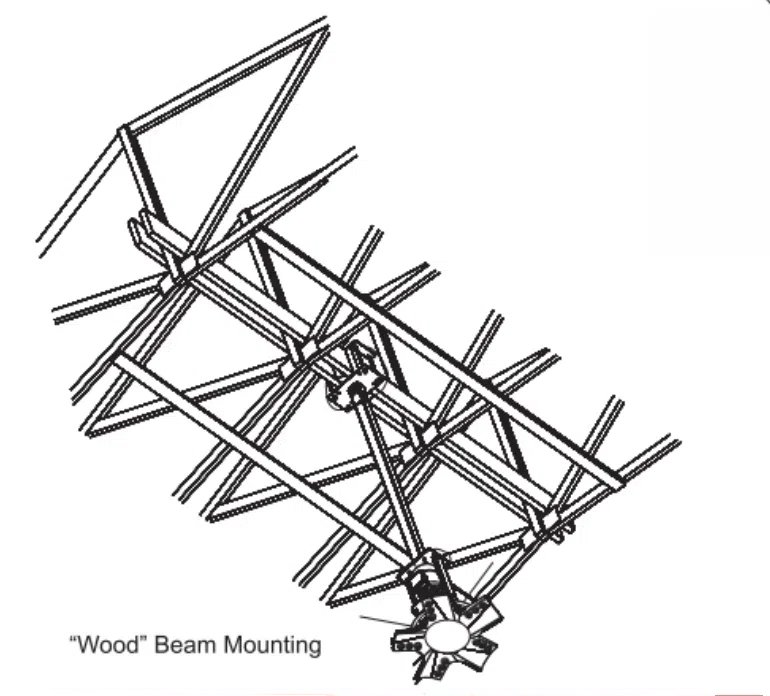

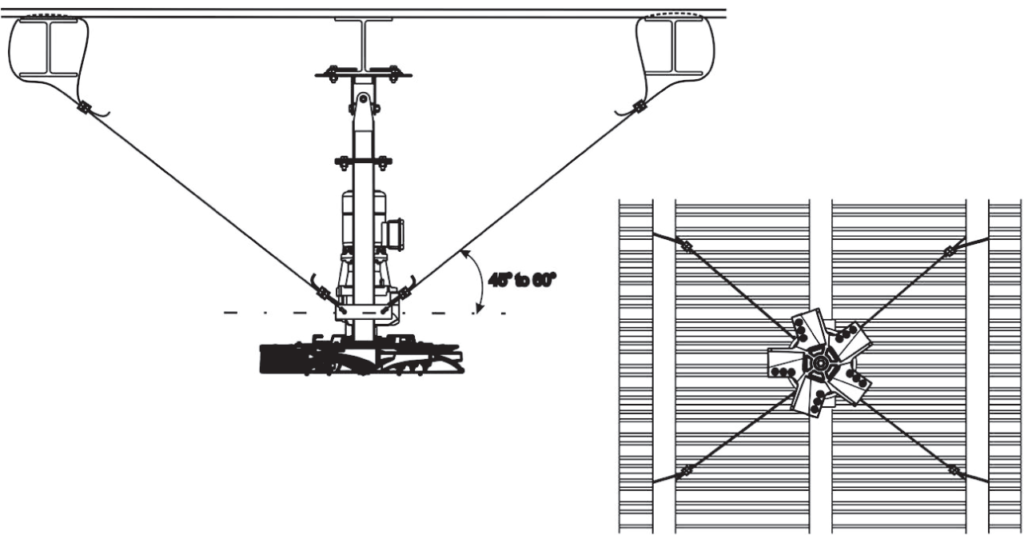

Purlin "Z " Mounting

"OWSJ" Mounting

"I" Beam Mounting

"Wood" Beam Mounting

"Concrete" Beam Mounting

Geajie industrial fans promote continuous air movement over large areas, creating a spacious and comfortable environment. In hot and humid weather, the fans can effectively reduce the room temperature by 2 to 4 degrees Celsius. During the heating season, the fan technology can eliminate temperature stratification between the floor and ceiling, which can have temperature differences of up to 15 degrees Celsius. This can effectively reduce the frequency of heating system usage, significantly lower energy consumption, and eliminate hot and cold spots.

Applicable Locations

- Warehouses: Maintain optimal temperature and humidity for goods and working environments through effective air circulation.

- Factories: Improve production environments, enhancing employee comfort and productivity.

- Commercial Buildings: Provide a comfortable environment for shopping centers, office buildings, etc.

- Sports Arenas: Ensure comfort for spectators and athletes.

- Airports: Improve air quality and temperature control in waiting and working areas.

- Livestock Farming: Enhance the living environment for livestock, reduce heat stress, and improve health levels.

Geajie industrial fans are the ideal choice for optimizing various large spaces and improving energy efficiency.

- Six-Blade High Airflow Low-Speed Fan

- Increasing Blade Angle Means More Airflow

- Low Operating Costs

- Ultra-Quiet Operation

- Low Energy Consumption

- Market’s Best Energy-Efficient Fan

- Simple Operation, Adjustable Speed, Forward and Reverse Control Functions

- Diameter Range from 8′ to 24′ (2.4m – 7.3m)

- Airflow Up to 400,000 CFM (Cubic Feet per Minute)

- Variable Frequency Drive Provides Soft Start and Full Variable Speed Operation

- Creates a Non-Disruptive Airflow

- Unique Positive 5-Degree Angle Airflow Radiation Technology

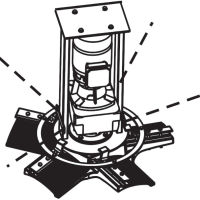

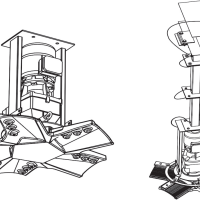

Leaf Disk

Hardware

Fan Blades

Extend Hanger

Transducer

Safe and Secure Connection Structure

| Performance Specifications | |||||||||||||

| Fan Size (DIA, M) | 7.4 M | 6.1 M | 4.9 M | 3.7M | 2.4M | ||||||||

| Motor Power | 1.5 KW | 1.5 KW | 1.1 KW | 0.75 KW | 0.75 KW | ||||||||

| Actual Amps at 230 Volt | 6.3 A | 6.3A | 3.5A | 2.8A | 2.8A | ||||||||

| Torque | 267 Nm | 227 Nm | 153 Nm | 58Nm | 46Nm | ||||||||

| Thrust | 1138 KG | 1094 KG | 767 KG | N/A | N/A | ||||||||

| Speed | 57rpm | 63 rpm | 73 rpm | 123 rpm | 154rpm | ||||||||

| Airflow | 187,693 L/S | 155,766 L/S | 85,976 LS | 63,313 LS | 19,886 LS | ||||||||

| Maximum Eff Diameter | 70.1 M | 61.0 M | 42.7 M | 24.3 M | 10.7 M | ||||||||

| Weight(No Mount) | 149.7 KG | 140.6 KG | 120.2 KG | 106.6 KG | 97.0 KG | ||||||||

| Noise Level | 64 dBA | 63 dBA | 62 dBA | 62 dBA | 60 dBA | ||||||||

Model | M700/M800 series | M600 series |

Fan diameter | 4900mm、5500mm、6100mm、7300mm | 3050mm、3660mm、4270mm |

Number of fan blades | 5 aviation aluminum fan blades | 5 aviation aluminum fan blades |

Installation height | 5 meters to 30 meters | 2.7 to 8 meters |

Install the hanger | Multi-angle adjustable | Multi-angle adjustable |

Extension rods | meter in length | meter in length |

Dynamical system | Direct drive motor, no reducer, lower energy consumption | Direct drive motor, no reducer, lower energy consumption |

Power supply type | AC/DC | AC/DC |

Maximum power | 990W | 240W |

Ambient temperature | -10~50°C, decelerate safely after exceeding this temperature. | -10~50°C, decelerate safely after exceeding this temperature. |

Controller | Human-computer interface, 10 speed control modes, up to 10 networked fans | Human-computer interface, 10 speed control modes, up to 10 networked fans |

Product Certification | CE CB certification | CE CB certification |