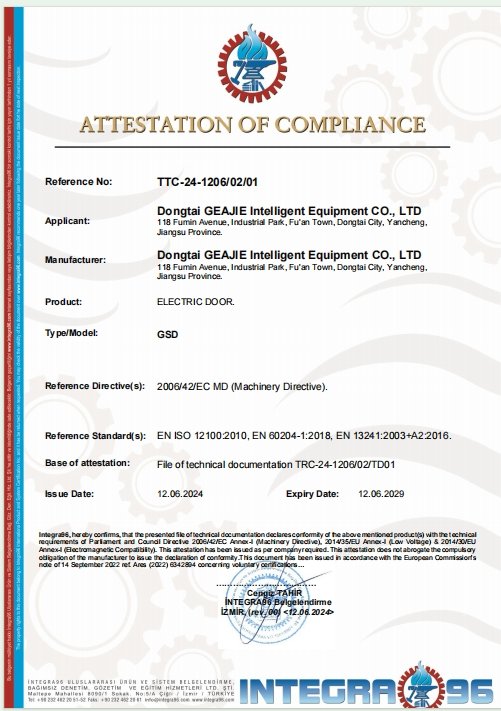

CE Certified: Our stacking doors adhere to European safety and quality regulations, offering you the assurance that they meet rigorous industry standards. Warranty: We provide a [X-year] warranty, ensuring the long-term performance and durability of your doors.

Speed, Durability, and Customization — All in One Seamless Solution

Strap fast doors are designed for high-traffic environments where speed and efficiency are critical. With robust construction and customizable options, these doors help you reduce downtime, save energy, and maintain smooth operations, all while ensuring long-lasting performance and safety.

How Stacking Doors Work:

Stacking doors feature a vertical folding mechanism that allows them to open and close smoothly without taking up extra space. This makes them ideal for facilities where space is limited, such as warehouses or production lines. The doors are constructed from durable materials and are designed to provide reliable performance in high-traffic environments.

Customization Options:

We offer stacking doors in various sizes, materials, and finishes to suit the specific needs of your facility. Options include insulated panels, custom colors, and automation for increased convenience and efficiency.

Stacking doors are ideal for warehouses, manufacturing facilities, logistics centers, and commercial buildings that need space-saving solutions with high durability and reliability.

Stacking doors fold vertically, which saves both floor and overhead space, making them perfect for facilities with space constraints or high-ceiling areas.

Yes, stacking doors can be equipped with insulated panels to improve energy efficiency, reducing heat loss and maintaining internal temperatures in climate-controlled areas.

Absolutely. We offer automation features, including remote control and sensor-operated systems, to improve operational efficiency and ease of use.

Stacking doors are made from durable materials such as reinforced steel, aluminum, or high-strength composite materials, ensuring long-lasting performance even in harsh environments.

Standard models are typically in stock and can be delivered within [X days]. Custom orders may require additional time based on specific requirements.

We offer a standard [X-year] warranty, ensuring reliable performance and long-term durability.

Our strap fast doors are designed to open and close quickly, reducing energy loss in climate-controlled environments. Insulation options are available for even greater energy savings, helping to lower your overall operational costs.

Success Story 1: Streamlining Operations for a Logistics Hub

Customer: Leading Logistics Center in Vietnam

Challenge: Frequent downtime due to slow and unreliable doors in high-traffic loading zones was causing delays in shipment processing. The facility needed fast, durable doors to maintain a steady workflow.

Solution: We installed custom-sized strap fast doors equipped with automation for seamless operation. These doors provided rapid open and close cycles, drastically reducing wait times and improving overall workflow efficiency. The robust materials and low-maintenance design ensured minimal operational disruption.

Result: The logistics center reported a 30% increase in loading efficiency, reduced energy costs due to faster door operation, and significant improvements in on-time shipment processing. The client expressed satisfaction with the doors’ durability and ease of use, resulting in smoother daily operations.

Success Story 2: Enhancing Efficiency in a Cold Storage Facility

Customer: Food Distribution Company in South Korea

Challenge: The cold storage facility was struggling with temperature fluctuations due to slow door systems that allowed cold air to escape, leading to higher energy consumption and product spoilage risks.

Solution: We implemented insulated strap fast doors with rapid open/close functionality to maintain optimal temperatures in the cold storage area. The doors were customized to fit the specific dimensions of the facility and included automation to optimize traffic flow and temperature retention.

Result: The client reported a 20% reduction in energy costs and significantly improved temperature control, which minimized product spoilage. The faster door operation enhanced workflow efficiency, enabling quicker access to storage areas without compromising temperature stability.

High-Speed Opening and Stable Operation: Are you looking for doors that open quickly and operate smoothly, optimized for strength selection and arrangement of wind-resistant ribs?

Optimal Solution for Large Span Openings and High Wind Pressure Environments: Do you need a door solution that is ideal for frequently used passages in large-span openings or environments with high wind pressure?

Applications in Specific Industrial Settings: Are you looking for doors suitable for large logistics passages, such as those in large equipment manufacturing plants, cement factories, sewage and waste treatment facilities, or underground parking garages?

Wind-Resistant Design Based on Local Conditions: Do you require doors designed with wind resistance according to local wind pressure conditions, ensuring even distribution of wind pressure across the door structure?

Flexible Top Design Options: Are you interested in doors with flexible top design options, allowing for either internal or external installation depending on the specific requirements?

Higher Standards with Double-Layer Flexible Lifting Doors: Do you need doors that meet higher demands, such as those that can utilize a double-layer flexible lifting door design?

- Designed to withstand wind pressure based on the local wind conditions of the application environment.

- The door curtain features an internal wind-resistant rib structure that evenly distributes wind pressure across the door.

- Flexible top design options, with the choice of either internal or external installation.

- For higher requirements, a double-layer flexible lift door can be used.

Strap-type fast doors are an efficient and multifunctional automated door solution suitable for various industrial and commercial environments. They are electrically operated, offering fast opening and closing speeds, and remote control capabilities, making them ideal for locations requiring frequent use and strict environmental controls. Here are the main reasons to choose strap-type fast doors:

Rapid Operation and Efficient Isolation

Strap-type fast doors can operate at speeds exceeding 0.6 meters per second, with a maximum speed of up to 1.4 meters per second. This high-speed functionality allows for quick separation of different areas, maintaining a dust-free and high-quality air environment within workshops, which is particularly important in industries like food processing, chemical manufacturing, and electronics where cleanliness is crucial.Multiple Integrated Functions

These doors provide various functions, including insulation, cooling, wind resistance, dust prevention, insect control, soundproofing, fire resistance, odor control, and lighting. They effectively protect the indoor environment from external factors, making them suitable for sectors like food, chemical, textile, refrigeration, electronics, printing, and warehousing, thereby enhancing safety and environmental quality.Automated Control and Easy Operation

Strap-type fast doors are equipped with an automated control system that supports remote operation, eliminating the need for manual opening and closing. This automation not only simplifies the process but also increases efficiency by reducing the time and labor required for door operation. Additionally, automated control significantly lowers noise levels, helping to maintain a quiet working environment.Excellent Sealing and Wind Resistance

The bottom of the door features an elastic PVC base fabric and weighted airbag, which closely conforms to uneven ground, providing excellent sealing performance. The door posts are equipped with sealing brushes that further enhance the seal, preventing dust and contaminants from entering. The doors also have outstanding wind resistance, withstanding wind speeds of up to level 10, making them suitable for large openings or areas with high external wind pressure.Flexible Control and Safety Features

The doors come with various control options, supporting both manual and automated systems to meet different production site requirements. They are equipped with infrared safety devices and warning lights to ensure prompt alerts and prevent accidents during operation. Safety devices also allow the doors to stop or reverse automatically when encountering obstacles, protecting both equipment and personnel.Significant Energy Savings

The design of strap-type fast doors helps save energy. The fast opening and closing function reduces the exchange of hot and cold air, lessening the load on air conditioning and refrigeration equipment, thereby conserving energy. Good sealing also helps maintain a stable indoor temperature, reducing energy waste.Wide Application Across Different Sites

Strap-type fast doors are suitable for logistics channels, large openings, and high wind pressure environments where frequent opening and closing are required. Their multifunctional features and high-performance make them ideal for use in food processing plants, chemical factories, electronics plants, cold storage facilities, supermarket refrigeration areas, and logistics centers.

Choosing strap-type fast doors can enhance efficiency and safety, save energy, and optimize the working environment, making them an ideal door solution for improving operational efficiency in various industrial and commercial settings.

Belt-driven high-speed doors are highly efficient doors widely used in industrial and commercial settings, particularly in areas requiring frequent opening and closing, such as workshops, warehouses, logistics centers, and food processing facilities. These doors are designed for quick operation and good sealing performance, minimizing energy loss. Below are the steps and precautions for properly operating a belt-driven high-speed door to ensure its safe and efficient use.

1. Inspect the Door Condition

- Before use, inspect the overall condition of the belt-driven high-speed door to ensure the door curtain, belts, and door frame are free from damage or wear.

- Check the tracks and rollers to ensure they are clear of obstructions and wear, and that all components are functioning correctly.

- Verify that all safety devices, such as photoelectric sensors, emergency stop buttons, and safety edges, are operational, and that all control buttons and indicator lights are working properly.

2. Prepare the Operating Area

- Clear the area around the door, removing any items that might obstruct door operation, such as stacked goods, tools, or equipment.

- Ensure there are no people or obstacles in the door’s path to prevent accidents during operation.

3. Activate the Control System

- Make sure the power supply is connected and activate the door’s control system.

- Use the “Up” or “Down” buttons on the control panel to operate the door and check the indicator lights to confirm the equipment is functioning correctly.

4. Operate the Door

- Press the “Up” button to slowly raise the door to the desired height, ensuring smooth movement along the tracks without sticking.

- When the door is fully open, ensure it remains securely in place to prevent accidental closing.

- To close the door, press the “Down” button to lower it slowly to the fully closed position, ensuring the path is clear of any obstructions.

5. Ensure the Door is Securely Locked

- After closing the door, check that the locking system and safety devices are correctly engaged to prevent the door from opening unexpectedly when unattended.

- Confirm the door is securely locked and check the lock status indicator light (if available) for proper display.

6. Perform Regular Inspections and Maintenance

- Regularly inspect all door components, including the door curtain, belts, tracks, rollers, and seals, to ensure they are not worn or damaged.

- Lubricate the tracks and moving parts to maintain smooth operation, and check all fasteners and bolts to ensure they are secure.

- Periodically test all safety devices to ensure they function properly when needed.

7. Shut Down the System and Clean the Area

- After use, shut down the control system and disconnect the power supply to prevent accidental activation.

- Clean the operating area, removing all tools and obstacles to keep the area tidy and ready for the next use.

Precautions

- Always wear appropriate personal protective equipment, such as safety shoes and gloves, when operating the door.

- Avoid standing under the door during operation to prevent injury in case of an unexpected fall.

- Ensure all operators are trained and familiar with the door’s operating procedures and safety guidelines.

- If any abnormal conditions are detected during operation, such as unusual noises or difficulty moving, stop using the door immediately and contact a professional technician for inspection and repair.

By following these steps and precautions, you can ensure the safe operation of a belt-driven high-speed door, extend its service life, and improve operational efficiency.

Two types of zipper high-speed doors are available: impact-resistant manual reset and impact-resistant automatic reset.

Excellent Wind Resistance:

Designed with internal or external wind-resistant rods that evenly distribute wind pressure, making it suitable for large-scale, wide-span, and high wind-pressure building passages.

Adaptable to Cold Environments:

Features a dual-seal track design with internal brushes and external EPDM (ethylene propylene diene monomer) rubber seals, ensuring superior sealing performance in cold climates.

Easy Maintenance:

Equipped with replaceable electrophoretic aluminum alloy wind-resistant rods, making curtain replacement easy, reducing maintenance costs, and accommodating door widths up to 8 meters, ideal for large passageways.

| Application Environment | Outdoor Door for Normal Temperature Conditions |

|---|

| Size Range | Width: 5000-12000mm Height: 3000-9000mm |

| Opening/Closing Speed | Opening Speed: 0.6-1.0m/s Closing Speed: 0.6m/s |

| Curtain Material | High-strength polyester fiber PVC curtain, standard thickness 0.8mm, other thickness options available |

| Curtain Color | Yellow, Orange, Blue |

| Window | Standard configuration: one row of windows, thickness 1.5mm |

| Track | Standard configuration: galvanized steel track, optional spray-painted color Stainless steel track optional |

| Roller and Motor Cover | Standard configuration: steel cover, optional spray-painted color Stainless steel option available |

| Opening Options | Three-key button, remote control, ground sensor, radar, pull rope, etc. |

| Safety Device | Track safety protection photoelectric sensor |

| Motor and Reducer | Lenze, Germany, 220V/380V, 0.55-1.5kw Other brands available |

| Control System | PLC and frequency converter |

| Wind Resistance | 700Pa |