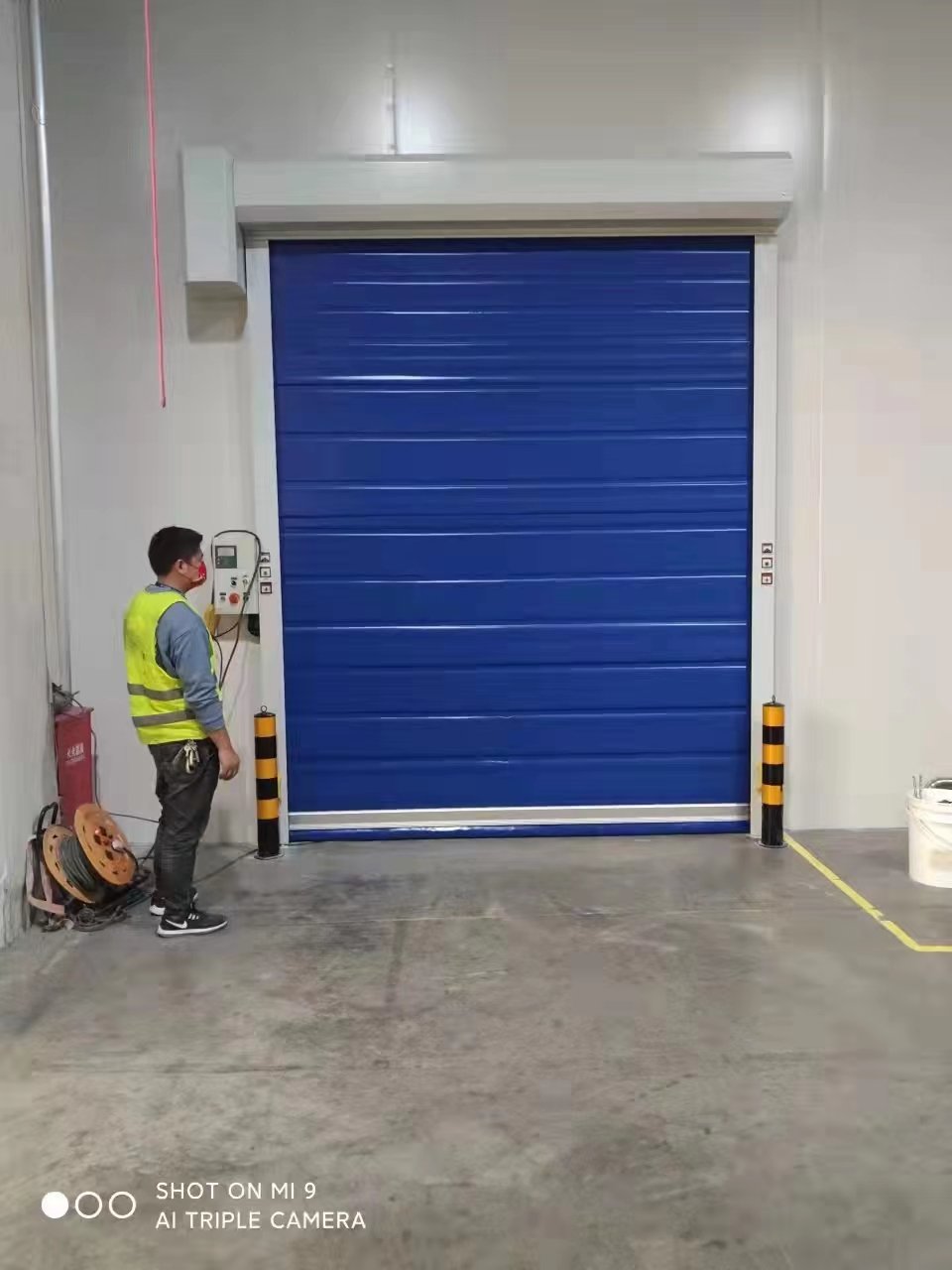

Our cold storage insulated fast doors are engineered to provide rapid access while maintaining critical temperature control. Designed for energy efficiency, these doors minimize air exchange, ensuring your products remain in optimal conditions. With durable insulation and customizable options, they offer the perfect solution for cold storage facilities looking to improve efficiency and reduce operating costs.

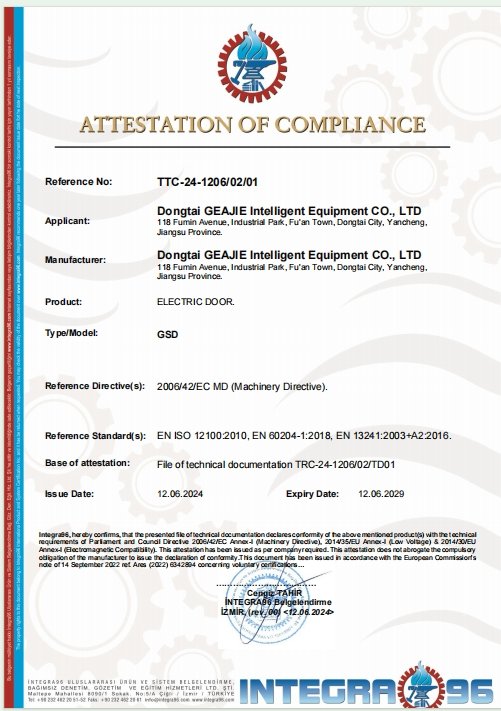

CE Certified: Our stacking doors adhere to European safety and quality regulations, offering you the assurance that they meet rigorous industry standards. Warranty: We provide a [X-year] warranty, ensuring the long-term performance and durability of your doors.

Maintain Ideal Temperatures and Boost Efficiency with High-Speed, Durable Solutions

Our cold storage insulated fast doors are designed to meet the demands of temperature-sensitive environments. With advanced insulation and rapid operation, these doors help you maintain stable internal temperatures while minimizing energy consumption. Customizable, durable, and equipped with smart safety features, they offer the perfect balance of efficiency and performance for cold storage facilities.

How Cold Storage Insulated Fast Doors Work:

Cold storage insulated fast doors are designed with rapid open-and-close functionality to minimize the loss of cold air and maintain internal temperature stability. The door panels are insulated to provide optimal thermal performance, making them perfect for environments where temperature control is critical, such as cold storage facilities or refrigerated rooms. These doors operate smoothly and efficiently, even in low-temperature settings, ensuring consistent and reliable use in high-traffic areas.

Customization Options:

Our cold storage insulated fast doors can be customized to meet the unique requirements of your facility. Available in various sizes and configurations, these doors can include options like advanced insulation technology, automated operation, and custom finishes to match your operational or aesthetic needs. Additional features such as built-in safety systems and rapid open-close mechanisms ensure both convenience and energy efficiency.

These doors are designed with advanced insulation and rapid operation to minimize air exchange, ensuring that cold air remains inside and temperatures stay stable.

Yes, the fast open-and-close functionality reduces air leakage, helping to lower energy consumption and maintain temperature control in cold storage environments.

Absolutely. Our cold storage insulated fast doors are built from high-quality materials that are engineered to perform reliably in low-temperature and high-traffic environments.

Yes, we offer various customization options, including door sizes, insulation levels, automated operation, and custom finishes to fit the specific needs of your facility.

The doors are constructed from robust materials designed to endure harsh conditions, frequent use, and low temperatures, ensuring long-lasting performance.

Yes, our cold storage insulated fast doors are equipped with advanced safety features, including motion sensors and safety edges, to ensure accident-free operation.

Installation time can vary depending on the size and customization of the door, but standard installations typically take [X days]. Custom orders may require additional time.

Yes, we offer automation options that include remote control and sensor-based systems for seamless operation, increasing efficiency and convenience in fast-paced environments.

Success Story 1: Improving Temperature Control in a Food Processing Plant

Customer: Major Food Processing Facility in Korea

Challenge: The facility was facing challenges in maintaining stable temperatures in their cold storage areas, leading to increased energy costs and the risk of product spoilage. The existing doors were slow and lacked adequate insulation, allowing significant cold air to escape during loading and unloading.

Solution: We installed customized cold storage insulated fast doors with advanced insulation and rapid open-close functionality. These doors minimized air exchange, kept cold air inside, and maintained consistent internal temperatures. The automation feature allowed for seamless operation, reducing downtime during busy production hours.

Result: The customer saw a 20% reduction in energy consumption and a significant improvement in temperature stability, leading to better product preservation. The fast doors also improved operational efficiency by speeding up the loading and unloading process. The client was impressed with the long-term energy savings and overall performance of the doors.

Success Story 2: Enhancing Efficiency in a Pharmaceutical Cold Storage Facility

Customer: Pharmaceutical Distribution Center in Vietnam

Challenge: The facility needed to maintain strict temperature controls for sensitive medical products but was facing inefficiencies due to slow, outdated doors. Frequent door opening and closing led to temperature fluctuations, posing a risk to product quality and increasing energy costs.

Solution: We provided cold storage insulated fast doors equipped with high-performance insulation and automated controls. These doors offered rapid operation and ensured minimal air leakage, maintaining a stable cold environment. Custom sizing allowed the doors to fit seamlessly into the facility’s existing structure.

Result: The pharmaceutical company achieved a 30% reduction in energy usage and significantly improved temperature control, protecting their sensitive products from spoilage. The faster door operation also reduced downtime, allowing for a smoother workflow. The client was highly satisfied with the doors’ reliability and the boost in overall operational efficiency.

Reduced Opening Time to Minimize Heat Exchange: Are you looking for doors that reduce opening time, minimizing hot and cold air exchange, and thereby saving significant costs?

Excellent Insulation Performance: Do you need doors with good insulation performance that effectively prevent frost and ice buildup on the door curtain and door frame?

Anti-Collision Auto Repair Function: Are you facing challenges with accidental collisions causing damage? Would you benefit from doors with an automatic repair function to prevent cold air leakage and reduce repair costs?

- The door curtain is filled with 2-3CM thick insulation material, providing excellent thermal insulation.

- Short, timed up-and-down movements effectively prevent frost and ice buildup on the door curtain.

- A heating device within the door frame prevents the frame from icing over.

- The door features an anti-collision automatic repair function, reducing cold air loss and maintenance costs caused by accidental impacts.

Cold storage insulated fast doors are specifically designed for environments requiring efficient insulation and frequent logistical operations, making them ideal for industries like cold chain logistics, food processing, and pharmaceutical manufacturing. Combining excellent insulation with rapid operation, these doors are a perfect choice for such settings. Here are the main reasons to choose cold storage insulated fast doors:

Superior Insulation Performance

These doors feature a design with double-layer PVC curtains and an insulating layer of foam, effectively preventing heat transfer and minimizing cold air loss. This construction ensures consistent internal temperatures in cold storage, helping to reduce energy consumption and save costs.Rapid Opening and Closing to Boost Efficiency

Cold storage insulated fast doors are designed for quick opening and closing, allowing operations to be completed in a very short time. This rapid action minimizes temperature fluctuations and increases efficiency in logistics and operations, making them suitable for environments with frequent access, such as cold chain transportation and food processing areas.High Sealing Capability

Equipped with double sealing strips or airbag sealing systems, these doors provide excellent sealing performance, preventing external air from entering and cold air from escaping. High sealing capability is crucial for maintaining stable temperatures and product quality inside cold storage facilities.Durable and Reliable

These doors are built with a sturdy structure, offering high stability and durability for long-term, frequent use. Some models also include anti-freeze heating elements and defrosting devices to ensure smooth operation in low-temperature environments, preventing issues caused by freezing.Energy Efficient and Environmentally Friendly

By minimizing cold air loss and maintaining a constant cold storage temperature, these doors effectively reduce the energy consumption of cooling equipment, lowering operating costs and contributing to environmental protection.Wide Range of Applications

Cold storage insulated fast doors are widely used in industries that require strict temperature control, such as cold chain logistics, food processing, and pharmaceutical manufacturing. These doors help improve operational efficiency and ensure stable product quality during storage and transportation.

Choosing cold storage insulated fast doors ensures rapid operation and high insulation performance, improving work efficiency and reducing energy consumption. They are the ideal solution for maintaining a stable environment in cold storage and saving energy.

An insulated high-speed door is designed for environments that require a consistent temperature and frequent passage, such as cold storage facilities, food processing plants, pharmaceutical workshops, and other industrial settings. These doors provide excellent sealing performance while opening and closing quickly. Here are the steps and precautions for using an insulated high-speed door to ensure safe and efficient operation.

1. Inspect the Door Condition

- Before operation, check the overall condition of the insulated high-speed door to ensure the door curtain, tracks, and seals are free from cracks, damage, or wear.

- Inspect the drive system and rollers to ensure there are no obstructions or wear, and that all components are functioning correctly.

- Confirm that all safety devices (such as photoelectric sensors, emergency stop buttons, and safety edges) are working properly, and that all control panel buttons and indicator lights are displaying correctly.

2. Prepare the Operating Area

- Clear the area around the door, removing any items that might obstruct door operation, such as stacked goods, equipment, or tools.

- Ensure there are no people or obstacles in the door’s path to prevent accidents during operation.

3. Activate the Control System

- Make sure the power supply is connected and functioning correctly, then activate the door’s control system.

- Use the “Up” or “Down” buttons on the control panel to operate the door. Check the indicator lights to ensure the equipment is operating normally.

4. Operate the Door

- Press the “Up” button to slowly raise the door to the desired height, ensuring it moves smoothly along the tracks without sticking or showing abnormal behavior.

- When the door is fully open, ensure it stays securely in place to prevent accidental closing when unattended.

- To close the door, press the “Down” button to lower it slowly to the fully closed position, ensuring there are no obstacles in its path.

5. Ensure the Door is Securely Locked

- After closing the door, check that the safety devices and locking system are properly engaged to prevent the door from opening unexpectedly when unattended.

- Confirm the door is securely locked, and check the lock status indicator light (if available) to ensure it shows the correct status.

6. Perform Regular Inspections and Maintenance

- Regularly inspect all parts of the door, including the door curtain, tracks, seals, and drive system, to ensure they are not damaged or worn.

- Lubricate the tracks and moving parts to maintain smooth operation, and check all fasteners and bolts to ensure they are secure.

- Periodically test all safety devices to ensure they function properly when needed.

7. Shut Down the System and Clean the Area

- After use, shut down the control system and disconnect the power supply to ensure the equipment is completely turned off, preventing accidental activation.

- Clean the operating area, removing all tools and obstacles to keep the area tidy and ready for the next use.

Precautions

- Always wear appropriate personal protective equipment, such as safety shoes and gloves, when operating the door.

- Avoid standing under the door during operation to prevent injury in case of an accidental fall.

- Ensure all operators are trained and familiar with the door’s operating procedures and safety guidelines.

- If any abnormal conditions are observed, such as unusual noises or difficulty operating, stop using the door immediately and contact a professional technician for inspection and repair.

By following these steps and precautions, you can ensure the safe and efficient operation of an insulated high-speed door and extend its service life.