Our impact-resistant swing doors are built for demanding environments, offering high durability and the ability to withstand frequent collisions without damage. Ideal for warehouses, manufacturing facilities, and food processing plants, these doors ensure smooth operations in busy areas while minimizing maintenance and repair costs.

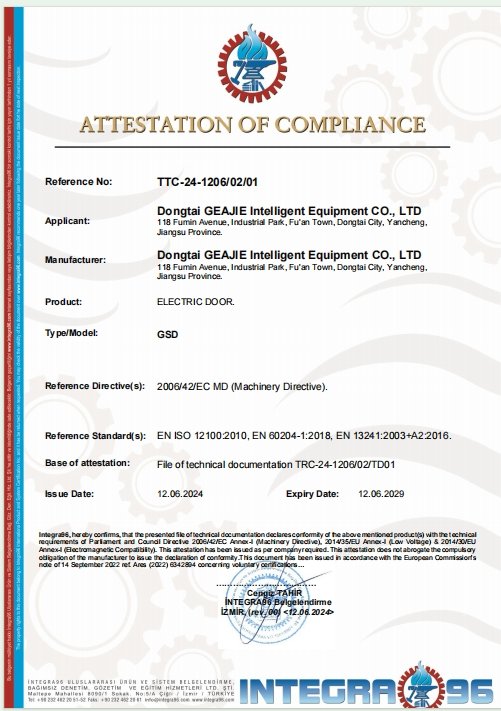

CE Certified: Our impact-resistant swing doors are compliant with European safety and quality standards, ensuring reliable performance in demanding environments.

Warranty: We provide a [X-year] warranty, ensuring the long-term durability and dependable operation of your doors.

Designed for Heavy Traffic, Built for Long-Term Performance

Looking for a door solution that stands up to constant impacts in high-traffic areas? GEAJIE impact-resistant swing doors are crafted from durable, flexible materials designed to withstand frequent use by forklifts, carts, and pallet jacks. With CE certification and a low-maintenance design, these doors ensure safety, longevity, and efficient two-way traffic flow. Upgrade your facility today with doors that offer reliability and peace of mind in the toughest environments.

How Impact-Resistant Swing Doors Work:

Our doors feature a flexible, durable design that allows them to swing in both directions, making them ideal for high-traffic environments. The impact-resistant materials absorb collisions without cracking or deforming, allowing for continued operation with minimal interruptions.

Customization Options:

We offer a variety of materials, sizes, and finishes to suit your facility’s specific needs. Whether you need enhanced impact resistance, visibility panels, or specific color schemes, we can tailor the doors to match your operational requirements.

These doors are ideal for industries such as logistics, manufacturing, food processing, and retail, where frequent impacts from equipment are common.

Yes, our doors can be customized with insulation options to maintain temperature control in cold storage or other climate-sensitive areas.

Absolutely. Our swing doors are designed for quick and easy installation, ensuring minimal disruption to your operations.

The flexible materials used in our doors are designed to absorb impacts and return to their original shape, preventing damage and reducing repair costs.

We offer a range of customization options, including door size, material type, visibility windows, and optional insulation for specific environments.

Standard models are typically in stock and can be delivered within [X days]. Custom orders may require additional lead time based on specifications.

Designed for heavy use in industrial environments, our impact-resistant swing doors are built to last, with minimal maintenance required.

We offer a standard [X-year] warranty, ensuring your doors continue to perform reliably for years to come.

Case Study 1: Improving Efficiency in a Cold Storage Facility

Client Background:

A leading cold storage facility faced challenges with their existing doors, which were frequently damaged by forklifts and pallet jacks during the fast-paced loading and unloading process. The constant repairs caused downtime, negatively impacting workflow and increasing maintenance costs.

Client’s Requirements:

The client needed a door solution that could handle heavy traffic and impacts without frequent maintenance, while also maintaining temperature control and safety in the cold storage environment.

Solution Provided:

We installed GEAJIE Impact-Resistant Swing Doors at key entry points throughout the facility. These doors, made from reinforced rubber, are designed to absorb impacts from equipment like forklifts and pallet jacks, reducing the risk of damage. The two-way swing mechanism enabled seamless traffic flow in both directions, improving the efficiency of material handling. Additionally, the low-maintenance design with few moving parts ensured long-term durability, reducing the need for frequent repairs.

Results:

After installation, the cold storage facility experienced a 30% reduction in door maintenance costs and significant improvements in operational efficiency. The doors’ impact-resistant design eliminated the frequent downtime caused by damaged doors, allowing workers to move goods in and out of the facility more smoothly. The client was extremely satisfied with the long-term reliability of the GEAJIE doors and saw a positive impact on their overall productivity.

Case Study 2: Enhancing Safety and Durability in a Manufacturing Plant

Client Background:

An automotive parts manufacturing plant was struggling with door durability issues in its high-traffic production area. Frequent collisions from carts and heavy equipment caused damage to the existing doors, leading to production delays and safety concerns for workers.

Client’s Requirements:

The client needed robust doors that could handle constant impacts while ensuring safe operation in a busy environment. Reducing downtime and minimizing repair costs were also critical priorities.

Solution Provided:

We installed GEAJIE Impact-Resistant Swing Doors in the high-traffic areas of the plant. The doors, constructed from flexible yet durable materials, were specifically chosen to withstand repeated impacts without breaking or requiring frequent repairs. The rounded edges and flexible material ensured worker safety by preventing injuries from collisions. The two-way swing mechanism allowed easy movement for carts and personnel, improving workflow on the production floor.

Results:

Following the installation, the manufacturing plant saw a significant reduction in door damage, virtually eliminating unplanned maintenance costs. Safety incidents related to door operation also decreased, thanks to the door’s design. Overall, production efficiency increased by 20%, as equipment and personnel were able to move through the facility more quickly and safely. The client praised the doors for their durability and effectiveness in a demanding industrial environment.

High-Speed Opening and Stable Operation: Are you looking for doors that open quickly and operate smoothly, making them ideal for environments with frequent trolley traffic?

Suitability for Diverse Environments: Do you need doors that are suitable for various environments, including areas that require water washing or cold storage?

PVC Windows for Visibility and Safety: Are you seeking doors with PVC windows that ensure clear visibility while enhancing safety?

Applications in Specific Industries: Do you require doors that are widely applicable in sectors such as meat processing plants, shopping malls, supermarkets, warehouses, and hospitals?

- Designed to withstand wind pressure based on the local wind conditions of the application environment.

- The door curtain features an internal wind-resistant rib structure that evenly distributes wind pressure across the door.

- Flexible top design options, with the choice of either internal or external installation.

- For higher requirements, a double-layer flexible lift door can be used.

Impact-resistant swing doors are a preferred choice for many commercial and industrial environments, especially those requiring high durability, collision resistance, and ease of operation. Here are the main reasons to opt for these doors:

Excellent Impact Resistance

The structure of impact-resistant swing doors features a core made of multiple layers of wood boards filled with polyurethane foam, with an outer layer of 1mm thick 304 stainless steel. This multi-layer design offers exceptional impact resistance, allowing the doors to withstand frequent use and physical impacts without easily getting damaged.Waterproof and Rustproof Capabilities

The edges of the door are reinforced with stainless steel or aluminum alloy channels and rubber sealing strips, ensuring superior waterproof and rustproof performance in humid or corrosive environments. This protective design extends the door’s lifespan, making it suitable for various harsh conditions.Gravity-Driven Closing Mechanism for Enhanced Durability

Impact-resistant swing doors utilize an eccentric shaft design instead of a traditional door closer, allowing the door to close automatically by its own weight. This mechanism reduces mechanical wear and prevents damage caused by rebound, thereby extending the door’s service life and minimizing maintenance needs.High Safety and Visibility

The door panel features a 5mm thick acrylic glass window, providing clear visibility and preventing accidental collisions with staff when the door is opened. The door is also equipped with crash strips and bumpers, allowing trolleys to push through without manual operation, enhancing efficiency and safety in the workplace.Maintenance-Free, Reducing Operating Costs

These doors are robustly designed for long-term durability and require minimal maintenance, reducing operational and maintenance costs. They are ideal for areas with high-frequency usage, such as logistics centers, cold storage facilities, and manufacturing workshops, where they can withstand demanding conditions.Wide Range of Applications

Impact-resistant swing doors are suitable for various industries, including food processing, warehousing, healthcare, and electronics manufacturing, especially in environments that require strict hygiene standards and ease of operation. Their sturdy design and long-lasting durability ensure reliability in different application scenarios.

Choosing impact-resistant swing doors provides superior collision resistance, waterproofing, and rustproofing, while also ensuring higher safety and operational convenience. They are the ideal choice for optimizing efficiency and safety in commercial and industrial environments.

Impact-resistant swing doors are widely used in industrial and commercial environments, particularly in areas that require frequent opening and closing and are prone to impact damage, such as warehouses, logistics centers, and food processing plants. These doors are made of high-strength materials, providing durability and resistance to impact. Here are the steps and precautions for operating impact-resistant swing doors to ensure safety and extend their service life.

1. Inspect the Door Condition

- Before use, check the overall condition of the impact-resistant swing door to ensure there are no cracks, deformations, or other damage on the door panels.

- Inspect the hinges and door frame to confirm they are not worn or loose, and that all components are functioning properly.

- Verify that all safety devices, such as cushioning mechanisms and emergency stop buttons, are working correctly, and that all indicator lights and control buttons are in good condition.

2. Prepare the Operating Area

- Clear the area around the door, removing any items that might obstruct the door’s movement, such as stacked goods, tools, or equipment.

- Ensure there are no obstacles or personnel in the door’s path to prevent accidents during opening or closing.

3. Activate the Door System

- Ensure the power supply is properly connected and activate the door system (for automatic doors).

- For manual doors, simply push or pull gently to open or close. For automatic doors, use the control panel buttons to operate the door.

4. Operate the Door

- To open the door, manually push or use the control button (for automatic doors) to slowly move the door to the desired position, ensuring it moves smoothly along the track.

- When the door is fully open, make sure it remains in a secure position to prevent accidental closing or shifting.

- To close the door, slowly push or press the button to bring the door to a fully closed position, ensuring the path is clear of any obstructions.

5. Ensure the Door is Securely Locked

- After closing the door, check if the locking mechanism is properly engaged to prevent unauthorized opening.

- Confirm the door is securely locked and check that the lock indicator light (if present) shows a secure status.

6. Perform Regular Inspections and Maintenance

- Regularly inspect all parts of the door, including panels, hinges, tracks, and seals, to ensure they are not worn or damaged.

- Lubricate the hinges and moving parts to maintain smooth operation, and check all fasteners and bolts to ensure they are tight.

- Test safety devices, such as cushioning mechanisms and emergency stop buttons, regularly to ensure they function properly when needed.

7. Shut Down the System and Clean the Operating Area

- After use, shut down the control system and disconnect the power supply (for automatic doors) to ensure the equipment is completely turned off, preventing accidental activation.

- Clean the operating area, removing all tools and obstacles to keep the area tidy and ready for the next use.

Precautions

- Always wear appropriate personal protective equipment, such as safety shoes and gloves, when operating the door.

- Avoid overloading the door or placing excessive weight on it to prevent damage to the structure or components.

- Ensure all operators are trained and familiar with the door’s operating procedures and safety guidelines.

- If any abnormal conditions are observed during operation, such as unusual noises or difficulty in movement, stop using the door immediately and contact a professional technician for inspection and repair.

By following these steps and precautions, you can ensure the safe use of impact-resistant swing doors, improve operational efficiency, and extend their service life.