1. Superior Thermal Insulation

Our doors are built with high-density polyurethane or polystyrene insulation, significantly reducing heat transfer and helping to maintain consistent internal temperatures. This is essential for facilities storing perishable goods, pharmaceuticals, and other temperature-sensitive items.

2. Airtight Seals for Energy Efficiency

Featuring precision-engineered seals around the door frame, our cold storage sectional doors prevent air leakage, reducing energy consumption and ensuring that your facility maintains the required internal temperature, even in extreme conditions.

3. Robust Construction

Made with corrosion-resistant materials such as galvanized steel or aluminum, these doors withstand the demanding conditions of cold storage environments, offering long-term durability with minimal maintenance required.

4. Frost and Condensation Protection

Our thermal break technology prevents frost and condensation build-up, ensuring smooth operation and protecting your products from moisture-related damage.

5. Customizable Solutions

From sizes and finishes to insulation levels and operation systems, GEAJIE cold storage doors can be fully customized to meet the exact needs of your facility, ensuring both efficiency and aesthetics.

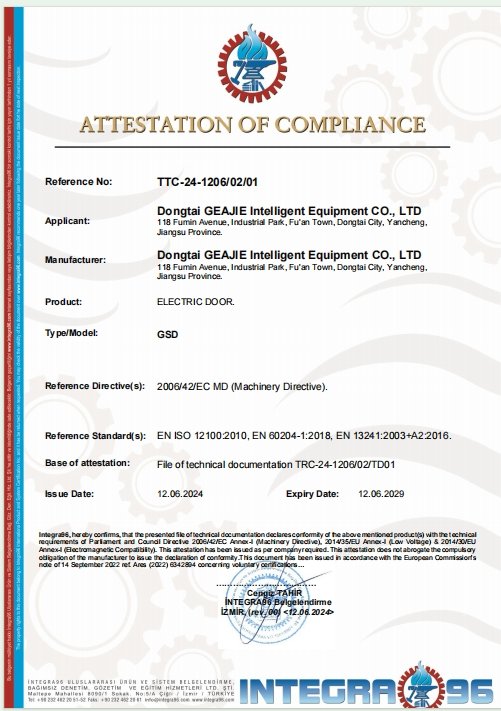

Certifications and Safety Assurance

Warranty: We offer a [X-year] warranty, guaranteeing long-lasting durability and peace of mind.

Food Processing Facility – Achieving 20% Energy Reduction

Client: A leading frozen food processing company

Challenge: High energy costs due to poor insulation and inefficient doors

Solution: GEAJIE installed high-density insulated sectional doors with advanced seals, helping maintain optimal internal temperatures. The result was a 20% reduction in energy consumption and improved operational efficiency.

Pharmaceutical Logistics Center – Ensuring Product Integrity

Client: A pharmaceutical logistics company specializing in vaccine storage

Challenge: Maintaining strict temperature control while reducing energy waste

Solution: GEAJIE’s cold storage insulated sectional doors provided excellent thermal regulation, resulting in a 15% drop in energy costs and improved product safety.

What makes GEAJIE Cold Storage Insulated Sectional Doors suitable for cold storage facilities?

How do these doors help with energy efficiency?

Can GEAJIE cold storage doors be customized?

Are there automation options available for these doors?

How do the doors prevent frost and condensation build-up?

What kind of maintenance do these doors require?

Are these doors durable enough for high-traffic cold storage environments?

What is the typical lead time for delivery and installation?

If you’re still unsure, our team can provide you with detailed information on how GEAJIE cold storage doors can benefit your facility. From insulation options to operating mechanisms, we’ll help you choose the best solution.

How Cold Storage Insulated Sectional Doors Work: Our sectional doors are equipped with high-performance insulation panels that help maintain consistent temperatures in cold storage environments. They are designed to operate smoothly and efficiently, with reinforced seals to prevent air leakage and ensure energy efficiency.

Customization Options: Choose from a variety of sizes, insulation levels, and finishes to suit your facility’s specific needs. We offer doors with extra insulation for extreme cold environments, as well as custom colors and finishes to match your branding.

1. Frost and Condensation Protection

Our doors are designed with advanced thermal breaks and insulated panels to prevent frost build-up and condensation. This ensures uninterrupted operation, even in the most extreme cold conditions, and protects the integrity of temperature-sensitive products.

2. Quick and Efficient Operation

GEAJIE cold storage doors are engineered for speed and efficiency. The fast opening and closing mechanisms reduce the time the doors remain open, helping to maintain internal temperatures and reduce energy waste during high-traffic operations.

3. Low Maintenance Requirements

Thanks to the use of corrosion-resistant materials and premium hardware, our cold storage doors require minimal maintenance. The durable construction ensures long-lasting performance, reducing downtime and repair costs over the lifespan of the doors.

4. Enhanced Safety Features

Safety is a top priority in cold storage environments. Our doors are equipped with photoelectric sensors, anti-crash protection, and emergency stop systems to safeguard personnel and equipment, ensuring safe operations even in fast-paced settings.

5. Space-Saving Design

The vertical lift mechanism of our sectional doors allows them to open and close efficiently without taking up floor space. This design maximizes available storage and operational space in your facility, making it ideal for confined or busy environments.

6. Custom Automation Options

In addition to manual operation, our cold storage doors are available with automation options. This includes remote control, motion sensors, and touchless systems, enhancing convenience and efficiency in high-traffic areas.

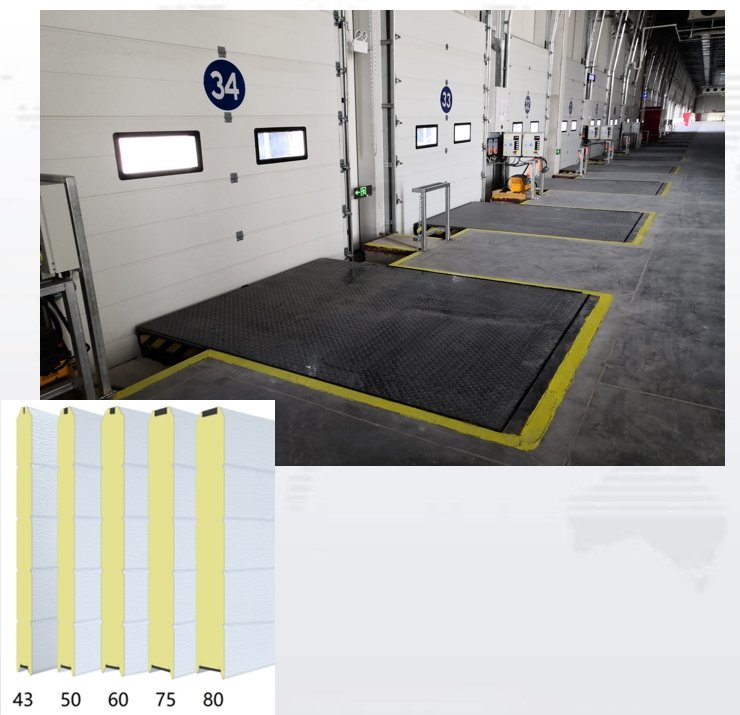

Energy Efficiency and Insulation for Cold Chain Logistics Loading Docks: Are you looking for solutions that better meet the energy efficiency and insulation requirements for low-temperature loading docks in cold chain logistics?

Good Thermal Insulation with Reduced Condensation: Do you need doors with excellent insulation performance that are less prone to condensation, making them suitable for low-temperature, humid environments?

Weight Balance of the Door Structure: Are you facing challenges in maintaining the balance of the entire door structure to ensure smooth operation and stability?

Compatibility with Various Building Structures: Are you seeking doors that can be adapted to different building structures and seamlessly integrate with various architectural styles?

Flexible Opening Mechanisms: Do you require doors that can be operated both electrically and manually to suit different operational needs?

- The door panel features a thickened polyurethane panel with a thermal break design, offering excellent insulation and reducing the likelihood of condensation.

- Many hardware components are made of aluminum alloy or stainless steel, making them more suitable for low-temperature and humid environments.

- Precisely calculated 60Si2Mn torsion springs ensure the overall weight balance of the door.

- The flexible track lifting system is adaptable to various building structures.

- A variety of door panel colors and designs are available to seamlessly integrate with different architectural styles.

- The door can be operated either electrically or manually.

Selecting cold storage insulated overhead doors can significantly enhance the performance and operational efficiency of a cold storage facility. Here are the key reasons to choose this type of door:

1. Superior Insulation Performance

Cold storage insulated overhead doors are filled with high-density polyurethane foam, providing excellent thermal insulation. With door panel thicknesses typically ranging from 100mm to 120mm, these doors effectively minimize cold air loss and maintain a consistent internal temperature within the cold storage. This high level of insulation not only helps reduce energy consumption but also significantly lowers the operational stress and costs of refrigeration equipment.

2. High Strength and Durability

These doors are constructed with robust aluminum alloy profiles or stainless steel, offering strong wind resistance and impact durability. The door panels are designed to withstand harsh operating conditions, preventing deformation and damage, thereby extending the door’s lifespan. Additionally, these doors maintain reliable performance even with frequent use, making them ideal for the high operational demands of cold storage environments.

3. Anti-Freezing Design

To address the specific low-temperature environment of cold storage, these doors are often equipped with anti-freezing electric heating systems. This heating system is installed at the junction of the door frame and door panel, effectively preventing the seals and panels from freezing and sticking under low temperatures, ensuring smooth opening and closing of the door in all extreme weather conditions.

4. Ease of Operation and Enhanced Safety

Cold storage insulated overhead doors feature advanced motor and control systems, enabling automated operation with fast and smooth lifting and lowering speeds. The doors are also equipped with multiple safety devices, such as photoelectric sensors, anti-break wire rope devices, and manual emergency operation systems, ensuring safety for both personnel and equipment in emergency situations.

5. Space-Saving and Efficiency Improvement

The overhead design of these doors allows them to slide up along tracks when opened, minimizing the space they occupy and avoiding the obstruction of passageways, unlike traditional swing doors. This design is particularly suitable for cold storage facilities that require ample space and high efficiency, enhancing material handling and loading/unloading operations.

6. Excellent Sealing

The door panel structure and sealing system of cold storage insulated overhead doors are meticulously designed to ensure excellent sealing when closed. This sealing capability prevents the leakage of cold air and the infiltration of warm air, maintaining a stable internal temperature in the cold storage and ensuring the quality and freshness of stored goods.

Choosing cold storage insulated overhead doors not only optimizes energy efficiency but also ensures safety and ease of operation, ultimately improving overall operational effectiveness and product quality. This makes them the ideal solution for cold storage door requirements.

Insulated overhead doors for cold storage are specifically designed for environments requiring excellent thermal insulation and sealing performance to maintain low temperatures, such as cold storage and cold chain logistics. To ensure safe operation and extend the door’s lifespan, follow these usage steps and precautions.

1. Inspect the Door Condition

- Before operating, check the overall condition of the overhead door. Ensure that the door panels are free of cracks, deformation, or other damage.

- Inspect the seals and door frame to ensure they are not worn or damaged and that all components are functioning properly.

- Ensure that all safety devices, such as photoelectric sensors and emergency stop buttons, are working correctly, and that all control buttons and indicator lights are in proper working order.

2. Prepare the Operating Area

- Clear the operating area around the door, removing any items that could obstruct the door’s movement, such as stacked goods, equipment, or tools.

- Ensure there are no obstacles or personnel in the door’s path to prevent accidents during opening or closing.

3. Activate the Control System

- Ensure the power supply is connected properly and activate the control system.

- Use the control panel buttons to select the “Up” or “Down” operation. Check all indicator lights to confirm the equipment is functioning correctly.

4. Operate the Door

- Press the “Up” button to slowly raise the door to the desired height, ensuring it moves smoothly along the tracks without any obstruction or irregular movement.

- When the door is fully open, make sure it remains in a safe position to prevent accidental movement.

- To close the door, press the “Down” button to slowly lower it to the fully closed position, ensuring the path is clear of obstacles.

5. Ensure the Door is Securely Locked

- After the door is fully closed, check if the locking mechanism is engaged to prevent unauthorized opening.

- Confirm the door is securely locked and check that the lock indicator light displays a secure status.

6. Check Insulation and Sealing Performance

- Regularly check the seals and insulation materials to ensure the door provides effective sealing when closed, preventing cold air from leaking.

- Inspect the insulation performance to ensure there are no air leaks or temperature loss.

7. Perform Regular Inspections and Maintenance

- Regularly inspect all parts of the door, including panels, tracks, rollers, and seals, to ensure they are not worn or damaged.

- Lubricate the tracks and rollers to maintain smooth operation and check that all fasteners are tight and secure.

- Test safety devices regularly to ensure they function correctly when encountering obstacles.

8. Shut Down the System and Clean the Operating Area

- After completing operations, turn off the control system and disconnect the power supply to prevent accidental activation.

- Clean the operating area, removing all tools and obstacles to keep the area tidy and ready for the next use.

Precautions

- When operating the door, always wear appropriate personal protective equipment, such as safety shoes and gloves.

- Do not overload the door or use it to support excessive weight to avoid damaging the structure or mechanical components.

- Ensure all operators are properly trained and familiar with the door’s operating procedures and safety guidelines.

- If any abnormal conditions are noticed, such as unusual noises or difficulty operating, stop using the door immediately and contact a professional technician for inspection and repair.

By following these steps and precautions, you can ensure the safe use of an insulated overhead door for cold storage, extend its service life, and improve operational efficiency.

Cold Storage Sectional Door Panel

The door panels feature thickened polyurethane with a thermal break design, offering excellent insulation and reducing the likelihood of frost formation.

Hardware

Most hardware fittings are made of aluminum alloy or stainless steel, making them more suitable for use in low-temperature and humid environments.

| Parameter | Description |

|---|

| Dimension Range | Width: 1500-6000mm, Height: 2000-6000mm |

| Opening Speed | 0.25m/s |

| Door Panel Material | Color-coated aluminum plate |

| Door Panel Thickness | 75mm |

| Track Material | Galvanized material, optional stainless steel |

| Window | Double-layer, optional electric heating window |

| Safety Devices | Standard, wire rope break protection device, torsion spring break protection device, wireless safety airbag |

| Colors | Standard colors: RAL9002 white gray, RAL9016 silver gray. Custom special colors |

| Wind Resistance | 700Pa |

Enhance Your Cold Storage Efficiency Today

Ensure optimal temperature control, reduce energy costs, and improve operational efficiency with GEAJIE’s Cold Storage Insulated Sectional Doors. Our doors are designed to meet the specific needs of your facility, providing durability, energy savings, and reliable performance.