1. Enhanced Safety & Visibility

Our transparent panels provide clear monitoring of operations, improving safety by allowing visibility both inside and outside your facility. This ensures a more efficient workflow and reduces the risk of accidents.

2. Modern Aesthetic

With sleek, contemporary design, GEAJIE transparent doors enhance the professional look of your facility, creating an inviting atmosphere that impresses clients and customers.

3. Durable Construction

Crafted from scratch-resistant tempered glass or polycarbonate, these doors are built to withstand tough environments while maintaining their clarity and durability.

4. Customizable Solutions

We offer various sizes, finishes, and operation systems, including manual and automated options, to fit your specific requirements. The doors can also be customized to match your facility’s color scheme and design preferences.

5. Energy Efficiency

Optional insulated panels help to maintain indoor temperatures, reducing the need for excessive heating or cooling. This translates into cost savings and environmental benefits.

6. Low Maintenance

The durable materials used in our transparent sectional doors require minimal upkeep, helping you save on long-term maintenance costs. Regular cleaning is all that’s needed to keep the doors looking and performing their best.

Modernizing a Car Showroom

Client Background: A luxury car brand needed a solution to modernize their showroom and attract more customers by enhancing visibility.

Solution: GEAJIE installed full-view sectional doors with tempered glass panels. The doors’ sleek design and transparency improved the showroom’s appearance and allowed customers to view the cars from outside.

Results: Foot traffic increased by 20%, leading to a noticeable rise in car sales within the first quarter.

Visibility and Efficiency Upgrade for a Logistics Warehouse

Client Background: A global logistics company required better visibility for its warehouse operations and wanted to improve energy efficiency.

Solution: We installed transparent sectional doors with polycarbonate panels. These doors allowed management to easily monitor operations without entering the warehouse, and the insulated design helped cut energy costs.

Results: Operational errors decreased by 15%, and the company saved 10% on energy bills.

How Transparent Sectional Doors Work: Transparent sectional doors provide natural light while ensuring the security of your facility. The panels, made from tempered glass or polycarbonate, are impact-resistant and weatherproof, making them ideal for both indoor and outdoor use.

Customization Options: We offer a variety of sizes, materials, and color choices to ensure your doors not only meet design requirements but also enhance operational efficiency.

What industries are transparent sectional doors suitable for?

How difficult is maintenance?

Can the doors withstand extreme weather?

Are there automation options?

Do the doors offer insulation?

Can I customize the doors?

Q: How long does the installation process take?

Q: What is the warranty on the transparent sectional doors?

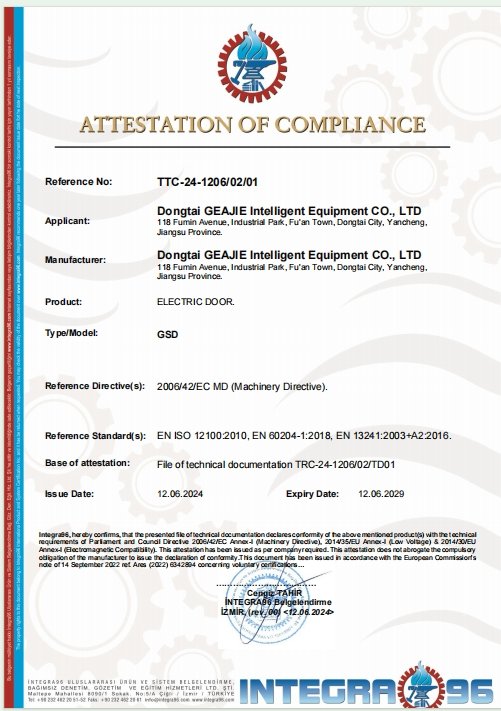

CE Certified: Fully compliant with European safety, health, and environmental standards, ensuring reliable performance and safety. Warranty: Backed by a standard [X-year] warranty, guaranteeing the long-term performance and safety of the doors.

Need for Daylighting and Visibility: Are you looking for door solutions specifically designed for environments that require natural light and visibility, such as car dealerships, fire stations, and showrooms?

Adaptation to Different Environmental Styles: Do you need doors that can complement and adapt to the style of various commercial environments?

Weight Balance of the Door Structure: Are you facing challenges with maintaining the balance of the entire door structure to ensure stability and smooth operation?

Compatibility with Various Building Structures: Are you seeking doors that are suitable for different building structures and can seamlessly integrate with various architectural styles?

Flexible Opening Mechanisms: Do you require doors that can be operated both electrically and manually, depending on the specific needs of the environment?

- The door panel is assembled from aluminum alloy profiles and features double-layer PVC windows, which can be combined with polyurethane panels.

- Many hardware components are made of aluminum alloy or other coated materials, making them suitable for different environmental styles.

- Precisely calculated 60Si2Mn torsion springs ensure the overall weight balance of the door.

- The flexible track lifting system is adaptable to various building structures.

- A variety of door panel colors and designs are available to seamlessly integrate with different architectural styles.

- The door can be operated either electrically or manually.

Fully transparent overhead doors are commonly used in industrial and commercial settings that require high visibility and natural light, such as car showrooms, service stations, and garages. These doors are made from transparent materials like tempered glass or polycarbonate, offering a modern appearance while ensuring safety. To use a fully transparent overhead door correctly and safely, follow these steps and precautions.

1. Inspect the Door Condition

- Before operating, check the overall condition of the overhead door. Ensure that the transparent panels are free of cracks, scratches, or other damage.

- Inspect the rollers and tracks to ensure they are free of obstructions or wear, and that all components are functioning properly.

- Verify that all safety devices, such as photoelectric sensors and emergency stop buttons, are working correctly, and that all indicator lights and control buttons are in proper working order.

2. Prepare the Operating Area

- Clear the operating area around the door, removing any items that could obstruct the door’s movement, such as stacked goods, equipment, or tools.

- Ensure there are no people or obstacles in the door’s path to prevent accidents during opening or closing.

3. Activate the Control System

- Ensure the door’s power supply is connected and activate the control system.

- Use the “Up” or “Down” buttons on the control panel to operate the door. Make sure the indicator lights show normal status, confirming that the equipment is functioning properly.

4. Operate the Door

- Press the “Up” button to slowly raise the door to the desired height, ensuring it moves smoothly along the tracks without any sticking or abnormal movement.

- When the door is fully open, make sure it remains in a safe position to prevent accidental sliding.

- To close the door, press the “Down” button to slowly lower it to the fully closed position. Ensure the path is clear of people or objects during this process.

5. Ensure the Door is Securely Locked

- After the door is fully closed, check if the locking mechanism is properly engaged to prevent accidental opening.

- Confirm the door is securely locked and check that the lock indicator light displays a secure status.

6. Perform Regular Inspections and Maintenance

- Regularly inspect all parts of the door, including transparent panels, tracks, rollers, and seals, to ensure they are not worn or damaged.

- Lubricate the tracks and rollers to maintain smooth operation and check all fasteners and bolts to ensure they are tight and secure.

- Periodically test all safety devices, such as photoelectric sensors and emergency stop buttons, to ensure they function correctly when needed.

7. Shut Down the System and Clean the Operating Area

- After use, shut down the control system and disconnect the power supply to ensure the equipment is completely turned off, preventing accidental activation.

- Clean the operating area, removing all tools and obstacles to keep the area tidy and ready for the next use.

Precautions

- Always wear appropriate personal protective equipment, such as safety shoes and gloves, when operating the door.

- Do not place excessive weight on the door to avoid overloading and potential damage to the door’s structure or mechanical components.

- Ensure all operators are trained and familiar with the equipment’s operating procedures and safety requirements.

- If any abnormal conditions are noticed during operation, such as unusual noises or difficulty in movement, stop using the door immediately and contact a professional technician for inspection and repair.

By following these steps and precautions, you can ensure the safe and efficient use of a fully transparent overhead door, extending its service life and enhancing overall operational efficiency.

Versatile Transparent Sectional Door

The door panels are assembled from aluminum alloy profiles and embedded with double-layer PVC windows. They can be combined with polyurethane door panels.

Premium Hardware Fittings for Enhanced Durability and Style

Most hardware fittings are made of aluminum alloy or other coated materials, suitable for the application environment’s style.

| Parameter | Description |

|---|---|

| Width Range | 1500-6000mm |

| Height Range | 2000-6000mm |

| Opening/Closing Speed | 0.25m/s |

| Door Panel Material | Aluminum alloy frame + double-layer transparent windows |

| Door Panel Thickness | 40mm |

| Track Material | Galvanized steel |

| Installation Position | Standard |

| Safety Devices | Steel wire rope break protection device, torsion spring break protection device, wireless safety airbag |

| Wind Resistance | Standard 450Pa, up to 700Pa |

| Color Options | Black (anodized aluminum finish), other colors available with powder coating |

Elevate Your Facility with GEAJIE Full-View Sectional Doors

See the Difference in Visibility, Efficiency, and Aesthetic Appeal