Providing robust and secure entry solutions for warehouses, factories, and logistics centers.

GEAJIE sectional doors are engineered for high-frequency use, combining exceptional durability with superior insulation. Whether you need space-saving vertical lifts or various installation options to fit different building structures, our sectional door series can meet all your diverse needs. With smart design and premium materials, make your operations safer and more efficient. Choose GEAJIE sectional doors today to add reliable protection to your facility!

What is Sectional Door?

Industrial sectional doors are widely used in the industrial and logistics sectors, offering excellent sealing, insulation, and wind resistance. They come in various panel types, materials, lifting methods, and drive options, with flexible customization to suit different application environments. Insulated sectional doors for cold storage are primarily used for cold chain logistics loading docks. The door panels are made of thickened polyurethane with thermal break technology, and when paired with other accessories, they better meet the energy-saving and insulation requirements of low-temperature unloading areas.

Choosing the right lifting mechanism for an industrial overhead door depends on several factors:

Building Structure: The lifting mechanism should be selected based on the building’s height, the size of the door opening, and the ceiling structure. Common lifting mechanisms include standard lift, vertical lift, and high lift. A standard lift is suitable for regular height door openings, a vertical lift is ideal for buildings with high ceilings, especially when maximizing door opening space is required, and a high lift is used when there is a high ceiling but a fully vertical lift is not necessary.

Frequency of Use: Choose a lifting mechanism based on how frequently the door will be used. For doors with frequent use, it is advisable to select a lifting mechanism that operates quickly and smoothly to enhance efficiency and prolong the door’s lifespan.

Door Weight and Material: The weight and material of the door also determine the lifting mechanism. Heavier doors require stronger lifting systems or additional balancing systems to ensure smooth operation.

Space Constraints: The available space above and on both sides of the door opening will influence the choice of lifting mechanism. Choose a mechanism that suits the available space to ensure the door operates without obstruction.

Safety Requirements: When choosing a lifting mechanism, consider the safety features of the door, such as anti-fall devices and buffers, to ensure the safety of both operators and goods.

By considering these factors, you can choose the most suitable lifting mechanism for your industrial overhead door needs.

High Thermal Insulation Our sectional doors feature insulated panels that reduce heat transfer, making them ideal for temperature-controlled environments such as warehouses and cold storage facilities. This helps in maintaining energy efficiency while keeping operational costs low. Heavy-Duty Construction Built with robust materials like galvanized steel or aluminum, our doors can withstand heavy industrial use and harsh environmental conditions. The corrosion-resistant finish ensures long-lasting durability. Smooth, Silent Operation Our doors are equipped with premium-quality hardware, including spring systems and precision tracks, ensuring quiet and smooth operation, even in high-traffic areas. Customizable Sizes and Designs Every business has unique needs, and our sectional doors can be tailored to fit your specific dimensions and design preferences. Choose from a range of finishes, colors, and panel designs to match your facility's aesthetic. Advanced Safety Systems Our sectional doors come with built-in safety mechanisms such as sensors, emergency stops, and anti-fall devices. These features protect both workers and equipment during operation, ensuring maximum safety at all times. Automated and Manual Options We offer both manual and automated sectional doors. Automated doors can be operated using remote control, motion sensors, or a control panel, providing greater convenience and ease of use.

Warehouses and Distribution Centers Sectional doors provide robust and reliable access for streamlined loading and unloading of goods, securing storage areas, and maintaining efficient workflow. They enhance security, lower energy costs, and optimize operational efficiency. Logistics Centers Designed for high-frequency use, sectional doors facilitate smooth and quick loading and unloading processes, improving operational efficiency and reducing downtime. Their ease of maintenance and durability make them ideal for busy logistics hubs. Manufacturing Facilities Sectional doors support the efficient movement of raw materials and finished products between delivery trucks and production floors. Their reliable performance and safety features ensure a smooth production flow, minimizing disruptions and handling time. Cold Storage and Refrigeration Units These doors are equipped with high-insulation properties to maintain the cold chain for temperature-sensitive products. They reduce energy consumption and ensure the safety and quality of perishable goods by preventing temperature fluctuations. Retail & Commercial Buildings Customizable sectional doors enhance the functionality and aesthetics of retail and commercial properties. They are designed for frequent use, providing secure, easy access while complementing the building's architectural style. Food and Beverage Industry Ensuring the safe and hygienic transfer of perishable goods, sectional doors in this sector help maintain product integrity and meet stringent food safety regulations. Their excellent sealing and insulation capabilities prevent contamination and spoilage. Pharmaceutical and Healthcare Facilities Sectional doors provide secure and efficient handling of medical supplies, pharmaceuticals, and equipment. They maintain the quality of sensitive products and improve the overall efficiency of logistics and inventory management. Automotive Industry Ideal for transferring automotive parts and components between delivery trucks and assembly lines, sectional doors help increase productivity, reduce handling damage, and streamline the supply chain process. Specialized Applications High-Security Doors: Enhanced security features protect facilities handling valuable or sensitive goods, preventing unauthorized access. Insulated Doors: Provide excellent temperature control, supporting energy efficiency and compliance with industry standards. Rapid Roll-Up Doors: Speed up access in high-traffic areas, improving workflow and reducing energy loss. Key Considerations for Choosing Sectional Doors Security: Ensure robust protection against unauthorized access. Insulation: Select appropriate insulation for temperature control and energy efficiency. Operation Type: Choose from manual, hydraulic, or motorized systems based on facility needs. Safety Features: Include sensors, emergency release mechanisms, and breakaway panels for enhanced safety. Durability and Maintenance: Opt for durable materials that require minimal maintenance. Sectional doors are an essential component in enhancing the efficiency and security of operations across various industries. By understanding their specific applications and requirements, businesses can select the right door solutions to optimize their operations.

Why Choose GEAJIE ?

Unmatched Expertise

With years of experience in manufacturing industrial equipment, GEAJIE understands the diverse and specific requirements of various industries. We leverage this expertise to design and produce sectional doors that perfectly match your operational needs, ensuring seamless integration into your workflow.

Superior Quality

At GEAJIE, we are committed to using only premium materials and cutting-edge technology in the production of our sectional doors. This dedication to quality ensures long-term reliability and optimal performance, even in the most demanding environments.

Tailored Solutions

Every sectional door we manufacture is fully customizable, from size and finish to lifting methods and drive options. This flexibility allows us to meet your unique specifications, providing solutions that are perfectly aligned with your business requirements.

Comprehensive Support

Our commitment to customer satisfaction extends beyond the sale. We offer comprehensive support, including expert installation, ongoing maintenance, and dedicated customer service, to keep your sectional doors operating at peak performance.

Fast and Efficient Delivery

We understand the importance of minimizing downtime. That’s why we prioritize fast, efficient delivery and installation, ensuring that your new doors are up and running without disrupting your operations.

Built for Longevity

GEAJIE sectional doors are engineered for durability and longevity, requiring minimal maintenance over their lifespan. This means you can rely on our doors to perform consistently, year after year, providing a solid return on investment.

Choose GEAJIE for top-quality, customizable sectional doors backed by industry expertise and comprehensive support. Experience the difference that reliability and performance make in your industrial operations.

Why GEAJIE Stands Out

- Proven Expertise: GEAJIE has been an industry leader for years, delivering solutions that meet global standards.

- Commitment to Innovation: We continually invest in R&D to offer the most advanced door solutions.

- Excellent Customer Support: Our dedicated team provides full support from the selection process to installation and beyond.

Geajie Intelligent stands at the forefront of the sectional door industry, specializing in the development and production of high-quality sectional doors. Our unwavering commitment to excellence has established us as a global leader, delivering top-tier non-metallic sectional doors that meet the highest standards of safety and durability.

Our Product lineup consists of three distinct series.

- Enhanced Safety: Equipped with anti-drop mechanisms and sensors for safe operation.

- Custom Solutions: Choose from a range of styles and materials, including fully transparent and insulated options.

- Cost Efficiency: GEAJIE doors offer a perfect balance between quality and affordability, ensuring you get the best value for your investment.

Different needs require different dock doors. When you consider easy opening and closing, impact resistance with quick reset, long-term reliable use, and energy efficiency, you need an impact-resistant dock door. When you need fast opening speed, aesthetic appeal, and energy efficiency, you need an insulated sectional door. When your doors frequently require washing, such as in cold storage or supermarkets, you need impact-resistant swing doors.

Material: High-strength steel or aluminum panels, with insulation options available.

Opening Speed: Designed for quick, efficient operation.

Insulation: Polyurethane or polystyrene core for enhanced thermal efficiency.

Wind Load Resistance: Suitable for high-wind areas, ensuring protection in harsh weather conditions.

Safety Compliance: Meets all relevant safety standards for industrial doors.

Motor technical specifications | |||

Model | GJ50S | GJ70S | GJ51S |

Output torque 100 Nm | 100 Nm 140 Nm | ||

Output shaft speed | 24 rpm | 24 rpm | 14 rpm |

Rated power 0.37 KW 0.37 KW 0.55 KW | |||

Rated voltage | 1×AC 230/400V | 2 x 点 ( 230/400 V | 1×AC 230 V |

Rated frequency | 50 H7 50H 50 Hz | ||

Control voltage | 24V | 24V | 24V |

Operating mode | S3-60% | S2 b() | S3-60% |

Safety current | 口安 | 门 | 口号 |

Protection level | IP 54 | D52 | 1p 52 |

Approximate weight | 40AK0 | 12.4 KC | |

Limit switch 15/30 5/30 5/30 | |||

Shaft diameter | 25.4mm/31.75 | 0 37 | 25.4mm/31.75mm |

Frequency inverter | 0.75 KW | ||

Control box limit adjustment function | Yes | Yes | Yes |

Fault display function Yes yes

Industrial Sectional Door Panel

Door panel materials: color-coated steel or aluminum. Thickness: anti-pinch door panel 40mm, insulated thermal break door panel 43mm. Door panel colors: RAL9002 white-gray, RAL9016 silver-gray, RAL1023 yellow, RAL5005 blue, RAL3002 fire red, custom colors available. This door panel is suitable for standard industrial sectional doors.

Large-span insulated door panel

Door panel materials: color-coated steel or aluminum. Thickness: reinforced door panels: 43+60mm, 43+90mm, 50+120mm. Door panel colors: RAL9002 white-gray, RAL9016 silver-gray, RAL1023 yellow, RAL5005 blue, RAL3002 fire red, custom colors available. This door panel is suitable for large-span insulated sectional doors.

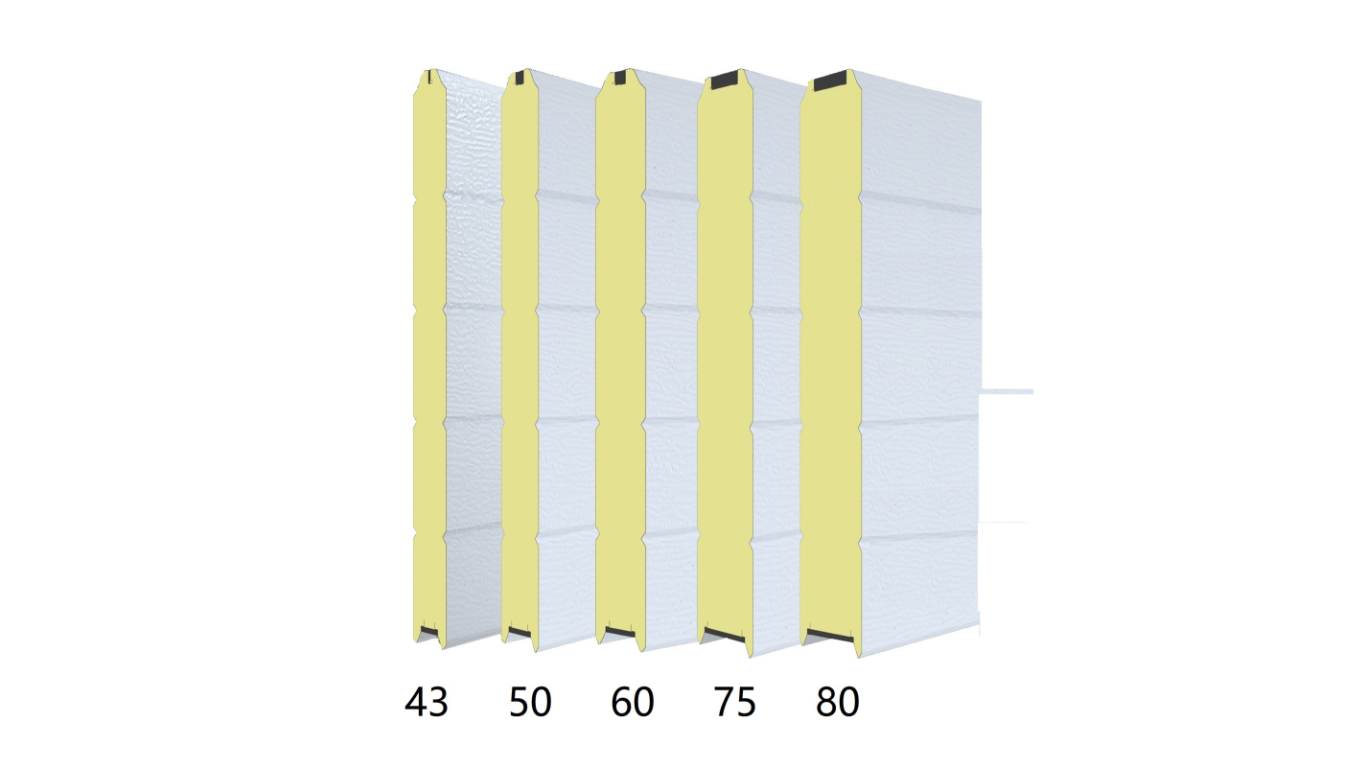

Cold storage insulated sectional door panel

Door panel materials: color-coated aluminum. Thickness: 43mm, 50mm, 60mm, 75mm, 80mm. Door panel colors: RAL9002 white-gray, RAL9016 silver-gray, custom colors available. This door panel is suitable for cold storage insulated sectional doors.

Extraordinary performance:

◇ Steel composite insulation sectional door is widely used in industrial plants, logistic warehouses,commercial buildings,fire-fighting field and etc.

◇ Concise and grand appearance is absolutely fit to building’s exterior.

◇Quick opening and closing speed,easy operation and low noise

◇ Extraordinary insulation function

Anti-wind and rain and anti-leakage

◇ Standard color:White RAL 9002,other colors also available

Strong structure:

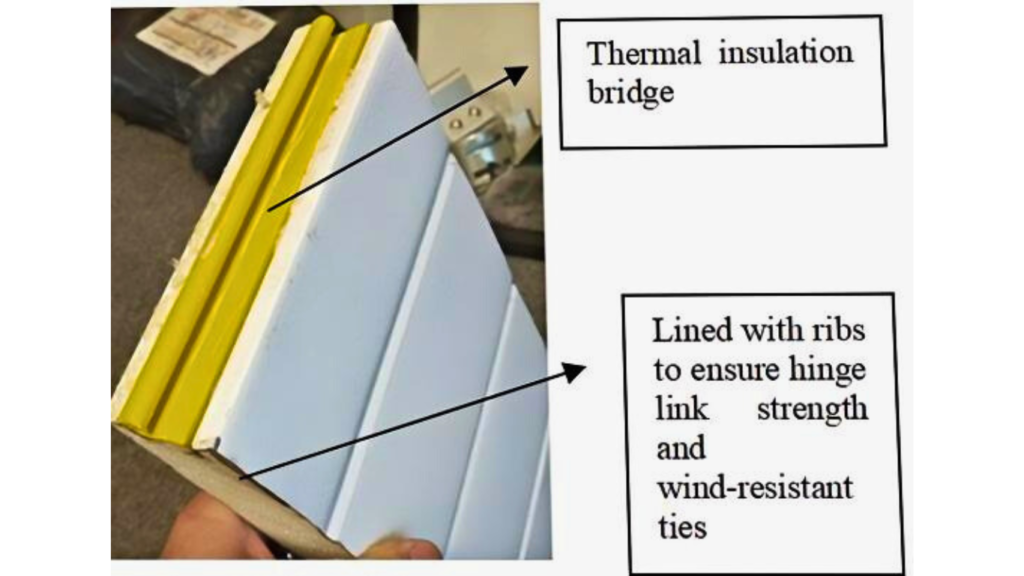

Industrial sectional door: The door panels are made of double-layer sandwich hot-dip galvanized steel sheets with a polyester surface treatment. The core material is a polyurethane insulation layer with a thickness of 42mm. The door edges are equipped with box-shaped edge sealing, and connecting hinges are mounted on the sealing, allowing the door to slide into the track. The bottom and top are fitted with top and bottom seals made of spherical vinyl resin, running along the width and height of the door, providing windproof, dustproof, and seepage-proof protection. The door balance system consists of torsion springs, pulleys, steel shafts, locking, and fixing flanges. The pulleys are wound with steel cables, which are connected to the anti-cable break device at the bottom of the door. Thus, in a balanced state, lifting the door without a motor is also very convenient.

Sealing performance of sectional doors

All sectional doors are equipped with top and bottom seals. Rubber seals are installed between all tracks and door panels to ensure a tight seal between the door and the track. The sealing performance of the entire door is maximized through the use of bottom seals, side seals, top seals, and inter-panel seals. Except for the inter-panel seals, all other seals are made of high-quality EPDM rubber. All sectional overhead doors equipped with top and bottom seals. Further, all tracks provided with seals between tracks and door panels to provide excellent leaves.

Excellent Wind Resistance

The special shape of the door panels and the ribbed surface treatment provide the sectional door with excellent wind resistance, capable of withstanding a level 12 typhoon. Wider doors can achieve sufficient wind resistance through external reinforcement ribs.

The inner and outer surfaces of the door panel are made of high-quality hot-dip aluminized zinc steel from Baosteel (0.45mm), with embossed grain texture. It is coated with two layers of fluorocarbon baked paint and one layer of surface paint (including primer), with a total thickness of 42mm. Sealing rubber is installed at the connections of each door panel to prevent thermal transfer and reduce heat loss.

Foam:The door core is made of polyurethane material (CFC-11 free) and is formed by high-density foaming, with a density of 48±2kg/m3.

Bottom Seals

The specialized bottom seals for industrial doors ensure complete contact with the ground, providing excellent airtightness.

Top Seals

The specialized top seals for industrial sectional doors ensure that when the door is closed, the seals fit snugly against the wall.

Side Seal

The side seals are installed on the track mounting angle plate and fit snugly against the door panel once installed.

One Window

Window specifications: 625mm*322mm, window material: plastic frame with double-layer acrylic glass.

2 Windows

You can choose 2 windows if necessary.

Window in rows

Select one or multiple rows of windows based on the door opening height. Windows can be placed at intervals of 1000 mm based on the door opening width.

Door in Door

Pedestrian door: A pedestrian door can be installed only if the door width is less than or equal to 5500mm. Pedestrian door dimensions: 900mm*1850mm.

Understanding the components of GEAJIE sectional overhead doors allows you to clearly grasp their functionality and capabilities. This knowledge not only helps you identify the areas you are investing in but also highlights the specific features and advantages of Geajie products. With this information, you can make informed purchasing decisions that meet your unique needs. Whether you are requesting custom features or ensuring that the equipment meets your exact objectives, our detailed explanations enable you to choose the solution that best fits your business.

Industrial Sectional Door Components Layout

1.Vertical Rail 10.Spring 19.Top Panel 28.Steel Cord 2.Support Angle for Rail 11.Spring-break Prevention 20.Vision Window 29.Steel-Cord-Break Prevention 3.Horizontal Rail 12.SBR Spring Bracket 21.Central Panels 30.Bottom Cap 4.Support Angle for Rail 13.Spring Bracket 22.Hinge 31.Breather 5.Side Seal 14.Door Opener 23.Bottom Panel 32.Central Seal 6.Shaft 15.Door Opener Control Box 24.Handle 33.Top Seal 7.Shaft Connector 16.Bumper 25.Bottom Seal 34.Top Seal Rack 8.Shaft Bracket 17.Roller 26.Bottom Roller 35.Top Seal Rack 9.Drum 18.Roller Bracket 27. Bottom Roller 36.Remote Controller Receiver

Remote Control

Safety Warning LIghts

Safety Warning LIghts

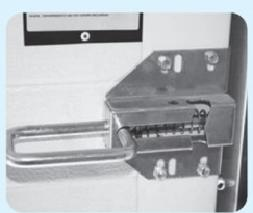

Internal sliding bolt. The door is fitted with an inside spring bolt as standard. Unless otherwise indicated this will be placed on the left hand side of the door as seen from the inside.

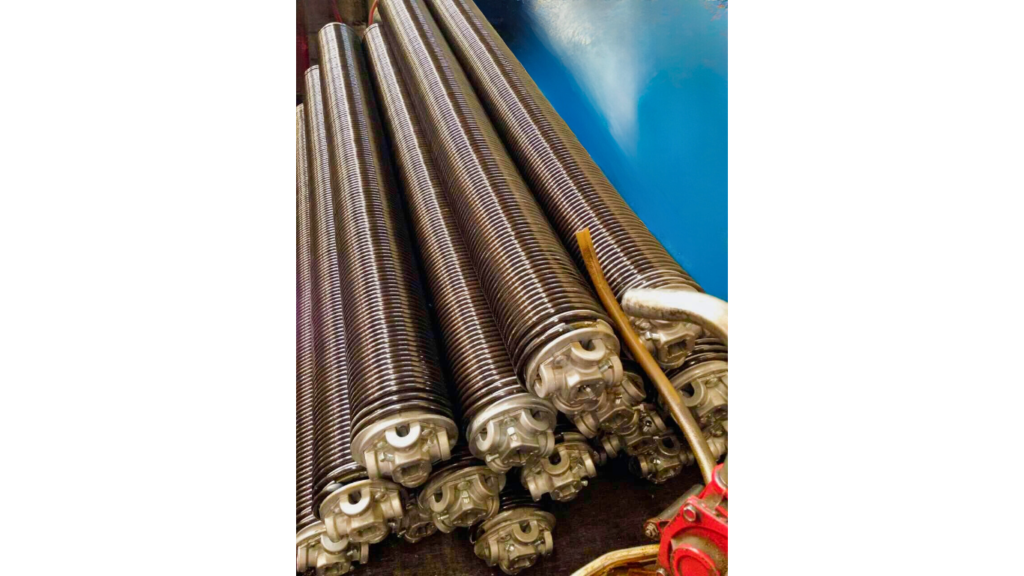

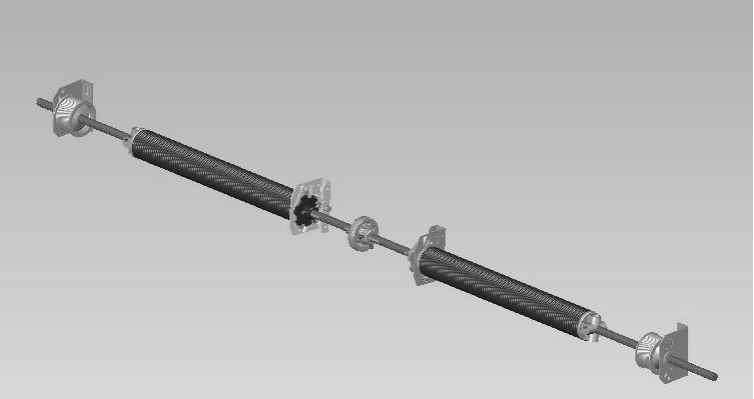

Balancing system

All doors balanced with heavy-duty springs made of high tensile wire, with a minimum life cycles of 30,000.Springs shall be low-stress, oil tempered, helical wound, torsion type on continuous shaft, Solid CRS or tubular as required, the material is 60Si2Mn.

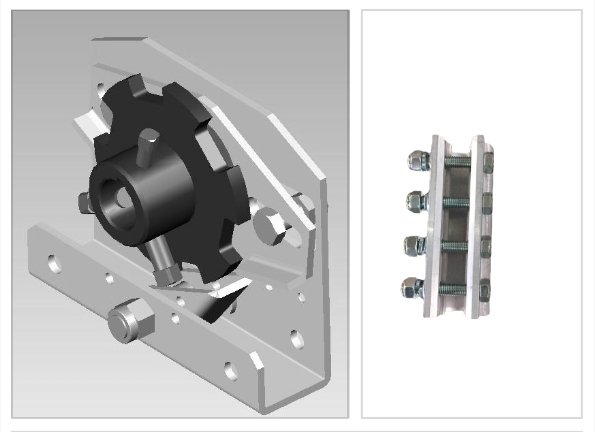

Spring breakage protection device

Each door is equipped with a cable break safety device. In the event of an unexpected cable break, this device effectively prevents the door from falling by clamping the side tracks.

Cable breakage protection device

Each spring has its own active cable breakage protection device. In the case of cable breaking, this system will stop the door from falling down by gripping onto the side guide.

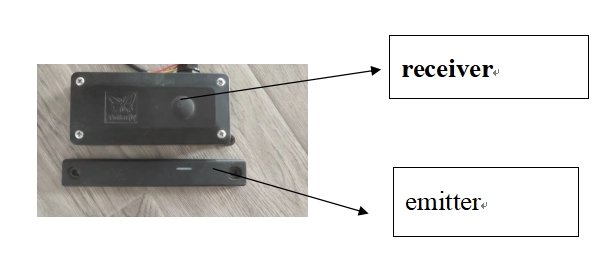

Obstacle detection device

Be used for motor-powered doors. A sensor which can detects obstacles is installed in the bottom seal of the door to insure the safety.

Safety Airbag Components

Safety airbags for industrial doors provide an essential cushioning mechanism, ensuring secure and controlled operation by preventing abrupt closures and mitigating impact risks.

GJ50S

GJ70S

GJ51S

The door panel is constructed entirely from aluminum, making it a lightweight and optimal choice for large-span installations in non-insulated environments. The 120mm thick wind-resistant bar at the bottom provides superior wind resistance once installed. To maintain balance, the door is equipped with precisely calibrated 60Si2Mn torsion springs. Its versatile track lifting options allow it to adapt to various building structures. The door can be operated both manually and electrically. It combines a sleek, corrosion-resistant design with lightweight construction, making it ideal for applications that do not require insulation.

Full-View Sectional Doors

The door panel is crafted entirely from aluminum, offering a lightweight solution that is ideal for large-span installations in non-insulated environments. It features a robust 120mm thick wind-resistant bottom bar, ensuring outstanding wind resistance once installed. The use of precisely engineered 60Si2Mn torsion springs guarantees the door’s optimal balance and smooth operation. With versatile track lifting options, it can adapt to a wide range of building structures. The door is designed for both electric and manual operation, providing maximum visibility, making it perfect for showrooms and exhibition spaces where aesthetics and functionality are equally important.

Industrial Sectional Door

Industrial Sectional Doors: Perfect for high-traffic environments with flexible customization options.

Oversized Insulated Sectional Doors:

Designed for large openings, offering superior thermal protection and wind resistance.

Cold Storage Insulated Sectional Doors:

Ideal for maintaining stable temperatures in cold chain logistics.

Lovely Customers

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradise

We've had Geajie's industrial sectional doors installed for over a year now, and their performance has been outstanding. The doors operate smoothly with minimal maintenance, and they are incredibly durable, standing up to frequent use and harsh weather conditions. Geajie’s product quality truly gives us peace of mind, and we trust them completely

Notice: Undefined offset: 0 in /home/u315884630/domains/tsunmi.net/public_html/wp-content/plugins/elementor/core/page-assets/data-managers/font-icon-svg/font-awesome.php on line 19

Since switching to Geajie's sectional doors, our warehouse efficiency has improved significantly. The doors open quickly and are easy to operate, which speeds up the movement of goods and greatly reduces energy loss. The insulation effect is excellent. We are very thankful to Geajie for providing such an outstanding product and service!

Notice: Undefined offset: 0 in /home/u315884630/domains/tsunmi.net/public_html/wp-content/plugins/elementor/core/page-assets/data-managers/font-icon-svg/font-awesome.php on line 19

Our company required large sectional doors with a challenging installation environment. The Geajie team not only provided professional customization services but also offered great support during the installation process. The doors are of excellent quality and meet all our requirements. We will definitely choose Geajie for future projects.

Design and Engineering

Using advanced CAD software, we develop detailed blueprints and models tailored to meet client specifications, ensuring precision and customization for each dock door.

Material Selection

We choose high-quality materials, including robust steel and reliable components, to guarantee durability and long-lasting performance.

Cutting and Fabrication

Steel sheets and other materials are precisely cut using laser or plasma technology, then welded and fabricated into the dock door’s essential structure.

Assembly

The fabricated components, including hinges, rollers, and panels, are meticulously assembled to create the dock door.

Surface Treatment

The dock door undergoes sandblasting and is then coated or painted to provide protection against corrosion and wear, ensuring a long lifespan.

Quality Control

Throughout the process, we conduct dimensional checks, weld inspections, and functional tests to maintain the highest standards of quality.

Hardware and Electrical System Installation

High-quality hardware and, where applicable, electrical systems are installed and tested to ensure smooth and reliable operation.

Final Inspection and Testing

A comprehensive final inspection and rigorous testing, including operational and safety checks, are performed to verify the correct and safe functioning of each dock door.

FAQs

Geajie Industry ensures that our products' quality and performance remain industry-leading.

What are Dock Doors?

What types of Dock Doors are available?

What materials are Dock Doors made from?

Can Dock Doors be customized?

How do Dock Doors improve warehouse efficiency?

What safety features do Dock Doors have?

How do I maintain Dock Doors?

How do I choose the right Dock Door for my facility?

Let's Talk About Your Dock Door Needs

Please provide the dimensions of the door opening you need, along with the required features (e.g., insulation, impact resistance, frequent washdown). With this information, we will promptly deliver a detailed solution and quotation. Act now!

Notice: Undefined offset: 0 in /home/u315884630/domains/tsunmi.net/public_html/wp-content/plugins/elementor/core/page-assets/data-managers/font-icon-svg/font-awesome.php on line 19