Industrial overhead doors are a versatile choice for a wide range of industrial and commercial environments, offering numerous design and functional benefits. Here are the key reasons to opt for industrial overhead doors:

Adaptable to Various Building Types

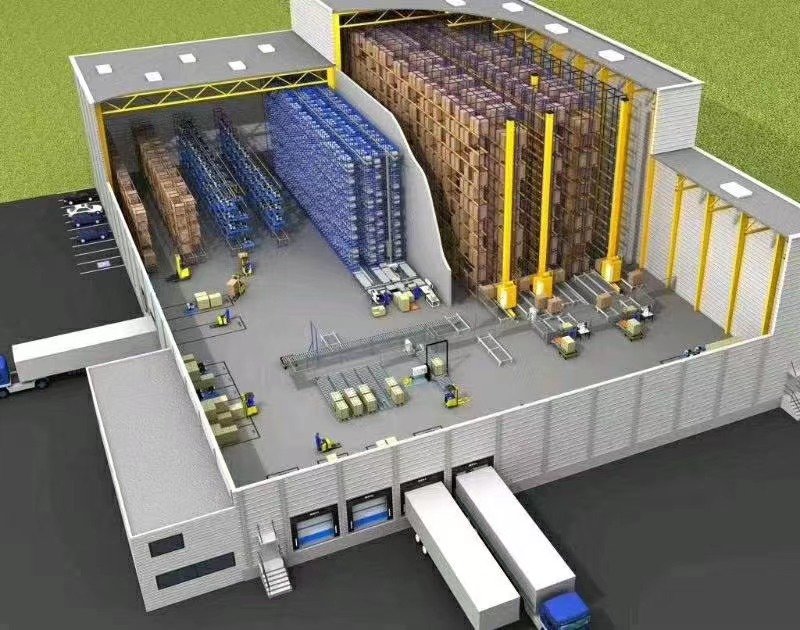

Industrial overhead doors are suitable for a variety of building structures and external environments. Whether it’s a factory, warehouse, hospital, supermarket, or cleanroom for precision semiconductors, these doors provide an efficient and reliable solution that meets the specific requirements of different settings.Excellent Sealing and Insulation

These doors feature EPDM rubber sealing strips around the frame, with additional safety airbags and sealing wings at the bottom, ensuring a tight seal between the door and the building. The double-layer coated steel panels, filled with rigid polyurethane foam, offer superior insulation, minimizing heat loss and reducing energy consumption.Efficient Automated Operation

Equipped with a robust motor system, industrial overhead doors support easy button controls for opening, stopping, and closing. The adjustable opening and closing speeds allow for quick and efficient operation, ideal for high-traffic areas. An emergency stop function is also included to enhance safety during unexpected situations.Durable and Sturdy Construction

With a door thickness of 50mm, made from double-sided 0.376mm thick color-coated steel panels and filled with high-density polyurethane foam (48kg/m³), these doors are built to withstand high wind pressure and impact. The tracks and rollers are also hot-dip galvanized twice to prevent rust and corrosion, ensuring a long lifespan of over 15 years.Comprehensive Safety Features

Industrial overhead doors are designed with multiple safety features, such as safety airbags, wire rope break protection devices, and spring break safety systems. These mechanisms prevent damage and injuries by reversing the door operation if obstacles are detected, ensuring safe usage under various conditions.Space-Saving Design

The vertical lift design of these doors maximizes space efficiency, requiring minimal interior and exterior room. This makes them ideal for environments where space utilization is critical. Additionally, the inclusion of observation windows enhances functionality by allowing operators to see outside the door without opening it.Long Service Life

Constructed with high-quality materials and meticulous manufacturing processes, industrial overhead doors are designed to last over 15 years with minimal maintenance requirements. Their durability and reliability make them a cost-effective long-term investment.

Choosing industrial overhead doors not only ensures superior sealing and insulation but also enhances safety and operational efficiency, making them suitable for a wide range of industrial and commercial applications. They are an ideal door solution for modern facilities looking to optimize performance and safety.

How Sectional Doors Work: Sectional doors consist of multiple modular panels that slide smoothly along tracks. This design allows them to function effectively even with limited overhead space. The panels glide effortlessly, ensuring reliable and efficient door operation.

Customization Options: We offer a wide range of materials, sizes, and colors to ensure that the doors meet your design preferences and operational needs.

GSD-N Standard Opening

When there is a clear space of 450-530 mm above the door opening, use this solution.

GSD-S Semi-vertical Opening

When the clear space above the door opening is greater than or equal to 600 mm, use this solution.

GSD-V Vertical Opening

When the clear space above the door opening is sufficiently ample, exceeding the door height by 400 mm, use this solution.

GSD-R Lowered Opening

When the clear space above the door opening is limited, only 300-450 mm, use this solution.

Sectional Doors with Dock Seals

Optimize warehouse operations with the seamless integration of sectional doors and dock seals, enhancing energy efficiency and security. This combination ensures smooth, secure loading and unloading, maintaining a controlled environment and improving workflow efficiency across various industries.

Sectional Doors and Dock Levelers

Optimize warehouse efficiency with the perfect integration of sectional doors and dock levelers, enhancing safety and operational effectiveness. This combination facilitates seamless, secure loading and unloading processes, maintaining energy efficiency and improving workflow in diverse industrial environments.

Sectional Doors, Dock Levelers, and Dock Seals

Achieve superior loading and unloading performance by combining sectional doors for robust security, dock levelers for smooth vehicle transition, and dock seals for optimal environmental control. This powerful trio ensures seamless operations, energy efficiency, and product safety across various industries.

Size Range | Width:1500-6000mm Height:2000-6000mm |

Opening/Closing Speed | 0.25m/s |

Door Panel Material | Color-coated steel plate or aluminum plate |

Door Panel Thickness | Anti-pinch door panel: 40mm Insulated bridge-cut door panel:43mm |

Windows | Single-layer, double-layer |

Pedestrian Door | Optional, upgradeable to a threshold-free pedestrian door |

Safety Devices | Standard, includes steel wire rope anti-break protection device, torsion spring anti-break protection device, and wireless safety airbag |

Wind Resistance | Standard 450PA, up to 700PA |

Drive Type | Manual or electric |

Color | Standard colors: RAL9002 white-gray, RAL9016 silver-gray, RAL1023 yellow, RAL5005 blue, RAL3002 fire red, custom colors available |

The industrial sectional door features double-layer sandwich hot-dip galvanized steel panels treated with a polyester surface process, with a polyurethane insulated core material, 42mm in thickness. The door's end surfaces are equipped with box-shaped edge seals, with connecting hinges mounted on the edge seals, allowing the door to fit securely into the track. The top and bottom are fitted with spherical vinyl resin seals along the width and height of the door, as well as side seals, making it windproof, rainproof, and leakproof. The door's balancing system consists of torsion springs, pulleys, a steel shaft, and locking and fixing flanges, with steel cables wound around the pulleys. These cables are connected to an anti-cable break device at the bottom of the door. This design ensures that in a balanced state, the door can be easily lifted without the need for a motor.

Effective Operation and Maintenance of Industrial Overhead Doors: A Step-by-Step Guide

Industrial overhead doors are essential components in warehouses, factories, and logistics centers, providing efficient and secure access to key areas. Proper usage and regular maintenance are crucial for ensuring their longevity, safety, and smooth operation. Below is a comprehensive guide to help you use and maintain your industrial overhead doors effectively.

1. Pre-Operation Inspection

- Check Door Condition: Ensure that door panels are free from cracks, damage, or excessive wear. Inspect tracks and rollers for obstructions and ensure smooth movement.

- Verify Safety Devices: Test all safety features such as photoelectric sensors and emergency stop buttons. Confirm that all indicator lights and control buttons are functioning correctly.

2. Prepare the Operating Area

- Clear Obstructions: Remove any items, equipment, or tools that could hinder the door’s movement. Ensure the pathway is clear of people and obstacles to prevent accidents.

3. Activate the Control System

- Power Connection: Ensure the door is connected to the power supply. Activate the control panel and check for normal status indications.

- Operate with Caution: Use the control panel to raise or lower the door smoothly, observing for any irregularities.

4. Operating the Door

- Open the Door: Press the “Up” button to raise the door to the desired height. Monitor its movement to ensure smooth operation.

- Close the Door: Press the “Down” button to lower the door safely. Check that the area is clear during the process.

5. Secure the Door

- Lock the Door: Once closed, verify that the locking mechanism is engaged. Ensure the door is securely locked and the indicator light confirms this.

6. Regular Inspections and Maintenance

- Inspect Components: Regularly check door panels, tracks, rollers, and seals for wear and damage. Lubricate moving parts as needed to ensure smooth operation.

- Test Safety Features: Regularly test safety devices such as sensors and emergency stops to ensure they function properly.

7. Shutdown and Area Cleanup

- Turn Off Power: After use, disconnect the power supply and shut down the control system to prevent accidental activation.

- Clean the Area: Remove any tools and debris from the operating area to maintain a safe and efficient workspace.

Key Precautions:

- Use Personal Protective Equipment (PPE): Always wear safety shoes, gloves, and other PPE when operating the door.

- Avoid Overloading: Do not exceed the door’s weight capacity, as this could damage the structure or mechanical parts.

- Operator Training: Ensure all operators are properly trained and familiar with safety protocols.

- Report Abnormalities: If you notice unusual noises or irregular movement, stop using the door immediately and contact a technician.

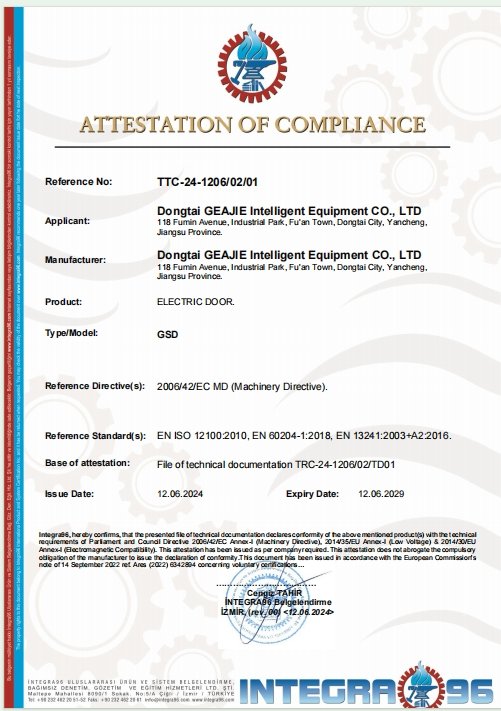

Benefits of Dongtai Geajie Sectional Doors:

Dongtai Geajie sectional doors help streamline operations by providing quick, reliable access to crucial areas, minimizing energy loss, and enhancing security. Their low-maintenance design reduces operational disruptions, allowing businesses to maintain high productivity and lower costs over time.

By following these steps and maintaining regular inspections, you can ensure the safe and efficient use of industrial overhead doors, improving overall operational performance and safety within your facility.

Our sectional doors are designed with cutting-edge technology to ensure smooth, automated operation. With options for remote control, motion sensors, and fully integrated security systems, our doors offer unparalleled convenience and safety. Emergency stop buttons and anti-crush mechanisms come standard, giving you peace of mind in any situation.

- The steel composite insulated sectional door is widely used in industrial plants, logistics warehouses, commercial buildings, and fire protection facilities.

- Its sleek and upright design perfectly complements the exterior walls of buildings.

- It offers high-efficiency opening and closing speeds, lightweight and low-noise operation, and exceptional insulation performance.

- It is windproof, rainproof, and waterproof.

- Standard color: White-gray RAL9002, with other colors available upon request.

- Warehousing: Improve storage facility efficiency with well-insulated sectional doors that ensure smooth logistics operations.

- Logistics and Distribution: Speed up cargo handling with fast-opening doors that facilitate quick loading and unloading processes.

- Manufacturing: Safeguard manufacturing areas while optimizing workflow with doors that offer both security and operational reliability.

- Cold Storage: Maintain stable, climate-controlled environments with doors that provide excellent insulation against temperature fluctuations.

- Retail and Commercial: Enhance the appearance and functionality of commercial spaces with stylish and efficient sectional doors designed for frequent use.

1. Robust Construction

Our sectional doors are constructed using high-quality, corrosion-resistant materials. Designed to endure frequent use and withstand harsh environmental conditions, these doors are perfect for high-traffic industrial areas.

2. Thermal Insulation

Featuring insulated panels, our sectional doors help regulate indoor temperatures, which is especially useful in cold storage facilities and temperature-controlled environments. By reducing heat transfer, they contribute to lower energy bills.

3. Smooth, Quiet Operation

The doors are engineered for silent and effortless operation, thanks to precision rollers and robust track systems. This ensures reduced wear and tear on parts, making the doors suitable for continuous use in demanding environments.

4. Safety Mechanisms

To protect workers and equipment, our sectional doors are equipped with advanced safety features such as anti-fall devices, photoelectric sensors, and emergency stop functions. These systems ensure safe door operation, preventing accidents and injuries.

5. Fully Customizable Options

We offer a range of customization options to suit your specific facility needs. From door size and color to operating systems (manual or automated), we work with you to deliver the perfect solution for your operational challenges.

At Dongtai Geajie Intelligent Equipment Co., Ltd., we pride ourselves on delivering sectional doors that combine durability, reliability, and exceptional performance to meet the diverse needs of various industries. Whether it’s a warehouse, logistics center, or manufacturing plant, our sectional doors are engineered to enhance security, energy efficiency, and operational convenience.

We recognize that every facility has unique requirements. That’s why we offer tailored solutions, customizing our sectional doors to fit your specific operational needs. From the initial consultation through to installation and after-sales service, our team of experts provides comprehensive support to ensure seamless functionality.

With a strong track record of serving businesses across Korea, Vietnam, Japan, and beyond, our global expertise is trusted to deliver high-quality industrial solutions. Our sectional doors are built to withstand heavy use and deliver proven performance, ensuring long-term reliability and a valuable return on investment for years to come.

- Built to Last: Made from high-strength materials such as galvanized steel or aluminum, our sectional doors are engineered for heavy-duty industrial use, providing long-term durability and resistance to wear.

- Energy Efficiency: With advanced thermal insulation, our sectional doors help maintain stable indoor temperatures, reducing energy consumption in temperature-sensitive environments.

- Seamless Operation: Equipped with high-performance components, our doors open and close smoothly, ensuring minimal disruption to daily operations.

- Custom-Built for Your Facility: Our sectional doors can be tailored to your specific needs, with various sizes, colors, and finishes available to suit your facility’s design and operational requirements.

Engineered for Durability, Safety, and Efficiency—Tailored to Your Facility’s Requirements

Whether you’re looking to improve energy efficiency or enhance security, our industrial sectional doors offer the perfect balance of strength, functionality, and customization. Built with advanced technology and designed for seamless integration, these doors are ideal for warehouses, logistics centers, and manufacturing plants.

Finding the perfect fit for your unique size requirements can be challenging, especially when dealing with non-standard width and height dimensions. If you’re struggling to maintain efficient temperature control due to inadequate insulation, or if high heating and cooling costs are a concern, it’s crucial to look for solutions that offer superior insulation properties.

For operations facing harsh weather conditions, such as high wind pressures, choosing doors with robust wind resistance is essential to ensure stability and security. Safety is another priority; if your current doors lack anti-pinch features or break protection, this could put your operations at risk.

Customization options like colors, windows, and pedestrian doors are often limited, making it difficult to find doors that align with your facility’s aesthetic and functional needs. Additionally, selecting between manual and electric drive types can be overwhelming, especially when balancing operational efficiency and budget constraints.

If security is a concern, inadequate door strength could lead to unauthorized access and accidents, compromising the safety of your facility. Frequent door malfunctions or breakdowns may lead to high maintenance and repair costs, further disrupting your operations.

Lastly, air and moisture infiltration can be problematic, affecting your indoor environment and potentially damaging stored goods. Addressing these common issues with the right sectional door solutions can significantly enhance operational efficiency, safety, and overall facility performance.

Warranty: all sectional doors come with a standard [X-year] warranty, guaranteeing peace of mind for long-term use.

Success Story 1: Enhancing Operational Efficiency in a Logistics Center

Background: A large logistics center was struggling with frequent loading and unloading processes, handling over 1,000 shipments daily. The traditional warehouse doors were slow and provided insufficient insulation, leading to inefficiencies and high energy costs. The facility needed a solution that could withstand heavy use and improve operational flow.

Challenges:

- Increase operational efficiency and reduce loading/unloading time.

- Provide excellent insulation to lower energy consumption.

- Improve security to prevent unauthorized access to the warehouse.

Solution: The logistics center installed GEAJIE sectional doors, equipped with a high-speed electric drive system, allowing the doors to open and close in seconds. The doors were designed with 40mm insulated panels, enhancing thermal performance. An integrated smart control system was also included to ensure safe and reliable operation in high-frequency use environments.

Results:

- Increased operational efficiency by 30%, reducing loading/unloading time by 25%.

- Stable internal temperature resulted in a 20% reduction in energy costs.

- Enhanced security, preventing unauthorized entry into the facility.

Customer Testimonial: “Since installing GEAJIE sectional doors, our logistics operations have become significantly more efficient, and energy costs have been reduced. The reliability and safety of these doors have been invaluable to our center.”

Success Story 2: Optimizing Temperature Control in Cold Chain Storage

Background: A cold chain logistics company needed to maintain sub-zero temperatures for sensitive food products in their storage facility. Their previous warehouse doors could not adequately seal off external heat, causing temperature fluctuations that placed additional strain on the refrigeration system and compromised product quality.

Challenges:

- Ensure stable internal temperatures to preserve the quality of temperature-sensitive goods.

- Enable fast and secure loading/unloading to minimize temperature loss.

- Accommodate frequent usage without compromising door integrity.

Solution: The company implemented GEAJIE’s cold storage sectional doors, featuring double-layer insulated panels and low-temperature seals that effectively block external heat. The high-speed operating system allows the doors to open and close within 2 seconds, significantly reducing temperature fluctuations. These doors were built to handle heavy usage while maintaining structural integrity.

Results:

- Maintained stable internal temperatures with a 40% reduction in temperature fluctuations.

- Reduced strain on refrigeration systems, saving 25% on energy costs annually.

- Improved product quality and customer satisfaction due to consistent temperature maintenance.

Customer Testimonial: “GEAJIE’s cold storage sectional doors have greatly improved our cold chain operations. They offer superior insulation and quick access, reducing energy loss and ensuring our products remain at the optimal temperature.”

Sectional doors are ideal for warehouses, manufacturing facilities, logistics centers, cold storage, and retail environments where efficient operation and energy efficiency are essential.

No. Sectional doors are made from durable materials and require minimal maintenance. Routine cleaning and basic hardware checks are all that’s needed to keep them running smoothly.

Not at all. Our sectional doors are available in both manual and automated options and are easy to operate without requiring specialized training.

Yes, we offer automated features, including remote controls, sensors, or smart control systems for enhanced convenience and efficiency.

Our sectional doors are equipped with high-performance insulation, making them ideal for temperature-controlled environments like cold storage or climate-sensitive warehouses.

Absolutely. We provide fully customized doors based on your specific size, color, and material needs.

Standard models are typically in stock and ready for immediate shipment. Custom orders may take longer depending on specific requirements, usually within [X days].

We offer a standard [X-year] warranty to ensure your door performs reliably for years to come.

Introduction to Edu_Learn LMS Plugin

Let us move forward with confidence, knowing that those who work tirelessly to innovate and enhance industrial overhead doors are building a safer and more efficient future for all.

Ensuring Smooth Operation and Safety Features

Welcome to our channel! Today, we’re excited to show you the final step in our door installation process: powering up and testing. After the door is securely installed, we connect the power to ensure everything runs smoothly. As you can see, the door opens and closes effortlessly, meeting our high-quality standards.

Our doors are designed for reliability and precision, providing a seamless operating experience. The built-in sensors ensure safe operation by automatically detecting any obstacles and stopping the door to prevent accidents, ensuring safety with every use. Whether it’s for warehouses, factories, or commercial spaces, our doors are built to handle heavy use while maintaining exceptional performance.

The control panel is user-friendly and customizable to meet your specific needs. Our products are not only powerful in function but also easy to operate, ensuring you experience maximum convenience and safety in your daily operations.

Thank you for watching! If you found this video helpful, please like and subscribe to our channel for more updates on our latest products and installations. For more information, visit our website or contact us directly. We look forward to providing you with the best solutions!

Our stacking doors are engineered for industrial and commercial spaces that require durability, space optimization, and high-performance. These doors fold vertically, providing a compact and efficient solution for facilities with limited space. Stacking doors are perfect for warehouses, manufacturing plants, and distribution centers, offering excellent security and operational efficiency.

About Us 这里换掉或删掉

CE Certified: Our stacking doors adhere to European safety and quality regulations, offering you the assurance that they meet rigorous industry standards. Warranty: We provide a [X-year] warranty, ensuring the long-term performance and durability of your doors.

Speed, Durability, and Customization — All in One Seamless Solution

Strap fast doors are designed for high-traffic environments where speed and efficiency are critical. With robust construction and customizable options, these doors help you reduce downtime, save energy, and maintain smooth operations, all while ensuring long-lasting performance and safety.

Detailed Product Information

How Stacking Doors Work:

Stacking doors feature a vertical folding mechanism that allows them to open and close smoothly without taking up extra space. This makes them ideal for facilities where space is limited, such as warehouses or production lines. The doors are constructed from durable materials and are designed to provide reliable performance in high-traffic environments.

Customization Options:

We offer stacking doors in various sizes, materials, and finishes to suit the specific needs of your facility. Options include insulated panels, custom colors, and automation for increased convenience and efficiency.

Stacking doors are ideal for warehouses, manufacturing facilities, logistics centers, and commercial buildings that need space-saving solutions with high durability and reliability.

Stacking doors fold vertically, which saves both floor and overhead space, making them perfect for facilities with space constraints or high-ceiling areas.

Yes, stacking doors can be equipped with insulated panels to improve energy efficiency, reducing heat loss and maintaining internal temperatures in climate-controlled areas.

Absolutely. We offer automation features, including remote control and sensor-operated systems, to improve operational efficiency and ease of use.

Stacking doors are made from durable materials such as reinforced steel, aluminum, or high-strength composite materials, ensuring long-lasting performance even in harsh environments.

Standard models are typically in stock and can be delivered within [X days]. Custom orders may require additional time based on specific requirements.

We offer a standard [X-year] warranty, ensuring reliable performance and long-term durability.

Our strap fast doors are designed to open and close quickly, reducing energy loss in climate-controlled environments. Insulation options are available for even greater energy savings, helping to lower your overall operational costs.

Success Story 1: Streamlining Operations for a Logistics Hub

Customer: Leading Logistics Center in Vietnam

Challenge: Frequent downtime due to slow and unreliable doors in high-traffic loading zones was causing delays in shipment processing. The facility needed fast, durable doors to maintain a steady workflow.

Solution: We installed custom-sized strap fast doors equipped with automation for seamless operation. These doors provided rapid open and close cycles, drastically reducing wait times and improving overall workflow efficiency. The robust materials and low-maintenance design ensured minimal operational disruption.

Result: The logistics center reported a 30% increase in loading efficiency, reduced energy costs due to faster door operation, and significant improvements in on-time shipment processing. The client expressed satisfaction with the doors’ durability and ease of use, resulting in smoother daily operations.

Success Story 2: Enhancing Efficiency in a Cold Storage Facility

Customer: Food Distribution Company in South Korea

Challenge: The cold storage facility was struggling with temperature fluctuations due to slow door systems that allowed cold air to escape, leading to higher energy consumption and product spoilage risks.

Solution: We implemented insulated strap fast doors with rapid open/close functionality to maintain optimal temperatures in the cold storage area. The doors were customized to fit the specific dimensions of the facility and included automation to optimize traffic flow and temperature retention.

Result: The client reported a 20% reduction in energy costs and significantly improved temperature control, which minimized product spoilage. The faster door operation enhanced workflow efficiency, enabling quicker access to storage areas without compromising temperature stability.

Case Study 1:

A large manufacturing plant installed our stacking doors to maximize space and improve efficiency on their production line. The vertical stacking mechanism helped free up floor space, allowing for smoother operations and increased productivity.

Case Study 2:

A logistics company needed doors that could handle high traffic and frequent use while saving space. Our stacking doors provided the perfect solution, offering fast operation and reducing energy loss by sealing the area quickly and efficiently.

Get More Information

Request a Custom Quote:

Contact us today to get a personalized quote for stacking doors that meet your facility’s specific needs.

Learn About Industry Trends:

Subscribe to our newsletter for updates on new products, industry trends, and innovative solutions.

Contact Us:

Have questions or need more information? Our team is ready to assist you in finding the best door solution for your business.

High-Speed Opening and Stable Operation: Are you looking for doors that open quickly and operate smoothly, optimized for strength selection and arrangement of wind-resistant ribs?

Optimal Solution for Large Span Openings and High Wind Pressure Environments: Do you need a door solution that is ideal for frequently used passages in large-span openings or environments with high wind pressure?

Applications in Specific Industrial Settings: Are you looking for doors suitable for large logistics passages, such as those in large equipment manufacturing plants, cement factories, sewage and waste treatment facilities, or underground parking garages?

Wind-Resistant Design Based on Local Conditions: Do you require doors designed with wind resistance according to local wind pressure conditions, ensuring even distribution of wind pressure across the door structure?

Flexible Top Design Options: Are you interested in doors with flexible top design options, allowing for either internal or external installation depending on the specific requirements?

Higher Standards with Double-Layer Flexible Lifting Doors: Do you need doors that meet higher demands, such as those that can utilize a double-layer flexible lifting door design?

- Designed to withstand wind pressure based on the local wind conditions of the application environment.

- The door curtain features an internal wind-resistant rib structure that evenly distributes wind pressure across the door.

- Flexible top design options, with the choice of either internal or external installation.

- For higher requirements, a double-layer flexible lift door can be used.

Strap-type fast doors are an efficient and multifunctional automated door solution suitable for various industrial and commercial environments. They are electrically operated, offering fast opening and closing speeds, and remote control capabilities, making them ideal for locations requiring frequent use and strict environmental controls. Here are the main reasons to choose strap-type fast doors:

Rapid Operation and Efficient Isolation

Strap-type fast doors can operate at speeds exceeding 0.6 meters per second, with a maximum speed of up to 1.4 meters per second. This high-speed functionality allows for quick separation of different areas, maintaining a dust-free and high-quality air environment within workshops, which is particularly important in industries like food processing, chemical manufacturing, and electronics where cleanliness is crucial.Multiple Integrated Functions

These doors provide various functions, including insulation, cooling, wind resistance, dust prevention, insect control, soundproofing, fire resistance, odor control, and lighting. They effectively protect the indoor environment from external factors, making them suitable for sectors like food, chemical, textile, refrigeration, electronics, printing, and warehousing, thereby enhancing safety and environmental quality.Automated Control and Easy Operation

Strap-type fast doors are equipped with an automated control system that supports remote operation, eliminating the need for manual opening and closing. This automation not only simplifies the process but also increases efficiency by reducing the time and labor required for door operation. Additionally, automated control significantly lowers noise levels, helping to maintain a quiet working environment.Excellent Sealing and Wind Resistance

The bottom of the door features an elastic PVC base fabric and weighted airbag, which closely conforms to uneven ground, providing excellent sealing performance. The door posts are equipped with sealing brushes that further enhance the seal, preventing dust and contaminants from entering. The doors also have outstanding wind resistance, withstanding wind speeds of up to level 10, making them suitable for large openings or areas with high external wind pressure.Flexible Control and Safety Features

The doors come with various control options, supporting both manual and automated systems to meet different production site requirements. They are equipped with infrared safety devices and warning lights to ensure prompt alerts and prevent accidents during operation. Safety devices also allow the doors to stop or reverse automatically when encountering obstacles, protecting both equipment and personnel.Significant Energy Savings

The design of strap-type fast doors helps save energy. The fast opening and closing function reduces the exchange of hot and cold air, lessening the load on air conditioning and refrigeration equipment, thereby conserving energy. Good sealing also helps maintain a stable indoor temperature, reducing energy waste.Wide Application Across Different Sites

Strap-type fast doors are suitable for logistics channels, large openings, and high wind pressure environments where frequent opening and closing are required. Their multifunctional features and high-performance make them ideal for use in food processing plants, chemical factories, electronics plants, cold storage facilities, supermarket refrigeration areas, and logistics centers.

Choosing strap-type fast doors can enhance efficiency and safety, save energy, and optimize the working environment, making them an ideal door solution for improving operational efficiency in various industrial and commercial settings.

Belt-driven high-speed doors are highly efficient doors widely used in industrial and commercial settings, particularly in areas requiring frequent opening and closing, such as workshops, warehouses, logistics centers, and food processing facilities. These doors are designed for quick operation and good sealing performance, minimizing energy loss. Below are the steps and precautions for properly operating a belt-driven high-speed door to ensure its safe and efficient use.

1. Inspect the Door Condition

- Before use, inspect the overall condition of the belt-driven high-speed door to ensure the door curtain, belts, and door frame are free from damage or wear.

- Check the tracks and rollers to ensure they are clear of obstructions and wear, and that all components are functioning correctly.

- Verify that all safety devices, such as photoelectric sensors, emergency stop buttons, and safety edges, are operational, and that all control buttons and indicator lights are working properly.

2. Prepare the Operating Area

- Clear the area around the door, removing any items that might obstruct door operation, such as stacked goods, tools, or equipment.

- Ensure there are no people or obstacles in the door’s path to prevent accidents during operation.

3. Activate the Control System

- Make sure the power supply is connected and activate the door’s control system.

- Use the “Up” or “Down” buttons on the control panel to operate the door and check the indicator lights to confirm the equipment is functioning correctly.

4. Operate the Door

- Press the “Up” button to slowly raise the door to the desired height, ensuring smooth movement along the tracks without sticking.

- When the door is fully open, ensure it remains securely in place to prevent accidental closing.

- To close the door, press the “Down” button to lower it slowly to the fully closed position, ensuring the path is clear of any obstructions.

5. Ensure the Door is Securely Locked

- After closing the door, check that the locking system and safety devices are correctly engaged to prevent the door from opening unexpectedly when unattended.

- Confirm the door is securely locked and check the lock status indicator light (if available) for proper display.

6. Perform Regular Inspections and Maintenance

- Regularly inspect all door components, including the door curtain, belts, tracks, rollers, and seals, to ensure they are not worn or damaged.

- Lubricate the tracks and moving parts to maintain smooth operation, and check all fasteners and bolts to ensure they are secure.

- Periodically test all safety devices to ensure they function properly when needed.

7. Shut Down the System and Clean the Area

- After use, shut down the control system and disconnect the power supply to prevent accidental activation.

- Clean the operating area, removing all tools and obstacles to keep the area tidy and ready for the next use.

Precautions

- Always wear appropriate personal protective equipment, such as safety shoes and gloves, when operating the door.

- Avoid standing under the door during operation to prevent injury in case of an unexpected fall.

- Ensure all operators are trained and familiar with the door’s operating procedures and safety guidelines.

- If any abnormal conditions are detected during operation, such as unusual noises or difficulty moving, stop using the door immediately and contact a professional technician for inspection and repair.

By following these steps and precautions, you can ensure the safe operation of a belt-driven high-speed door, extend its service life, and improve operational efficiency.

Opening Schedule

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradise

+04 367 4422

The search for eternal youth has to be a human imagination since times accident the search for eternal .

Your Complete Guide to Photography

Learn Python – Interactive Python

Introduction to Edu_Learn LMS Plugin

Your Complete Guide to Photography

Learn Python – Interactive Python

Introduction to Edu_Learn LMS Plugin

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradisematic country, in which

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradisematic country, in which

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradisematic country, in which

Latest ekit news

Ekit Latest News

Get the app in Playstore

Lets get the app and try ekit for free and no creadit card required

Two types of zipper high-speed doors are available: impact-resistant manual reset and impact-resistant automatic reset.

Product Features

Excellent Wind Resistance:

Designed with internal or external wind-resistant rods that evenly distribute wind pressure, making it suitable for large-scale, wide-span, and high wind-pressure building passages.

Adaptable to Cold Environments:

Features a dual-seal track design with internal brushes and external EPDM (ethylene propylene diene monomer) rubber seals, ensuring superior sealing performance in cold climates.

Easy Maintenance:

Equipped with replaceable electrophoretic aluminum alloy wind-resistant rods, making curtain replacement easy, reducing maintenance costs, and accommodating door widths up to 8 meters, ideal for large passageways.

Care About Us

Where Learning Begin

Building a strong sense of community in Greenville school

Community - Building Approaches

The power of Online training

01

Expert Trainers

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed auctor turpis eu arcu sagittis, id sagittis justo eli suscipit.

02

Unlimited Access

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed auctor turpis eu arcu sagittis, id sagittis justo eli suscipit.

03

24/7 Online Support

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed auctor turpis eu arcu sagittis, id sagittis justo eli suscipit.

| Application Environment | Outdoor Door for Normal Temperature Conditions |

|---|

| Size Range | Width: 5000-12000mm Height: 3000-9000mm |

| Opening/Closing Speed | Opening Speed: 0.6-1.0m/s Closing Speed: 0.6m/s |

| Curtain Material | High-strength polyester fiber PVC curtain, standard thickness 0.8mm, other thickness options available |

| Curtain Color | Yellow, Orange, Blue |

| Window | Standard configuration: one row of windows, thickness 1.5mm |

| Track | Standard configuration: galvanized steel track, optional spray-painted color Stainless steel track optional |

| Roller and Motor Cover | Standard configuration: steel cover, optional spray-painted color Stainless steel option available |

| Opening Options | Three-key button, remote control, ground sensor, radar, pull rope, etc. |

| Safety Device | Track safety protection photoelectric sensor |

| Motor and Reducer | Lenze, Germany, 220V/380V, 0.55-1.5kw Other brands available |

| Control System | PLC and frequency converter |

| Wind Resistance | 700Pa |