Welcome to the tutorial page for Dongtai Geajie Intelligent Equipment Co., Ltd, your trusted provider of industrial doors, loading systems, and intelligent equipment solutions. Below, we offer detailed guides and instructions on the installation, operation, and maintenance of our products to help ensure optimal performance and safety.

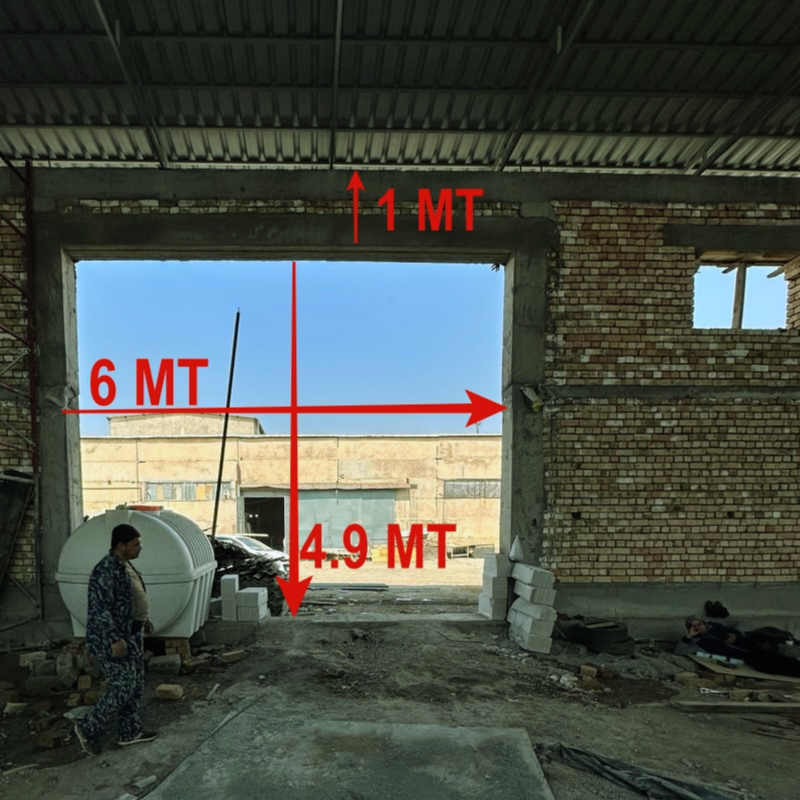

Not Sure How to Provide Accurate Dimensions?

- Preparation: Before installation, ensure all measurements of the opening are accurate and that the area is clean and free of obstructions.

- Step-by-Step Process:

- Attach tracks securely to the opening.

- Install the door panels starting from the bottom, ensuring each panel is level.

- Set up the counterbalance system for smooth door movement.

- Attach safety devices such as springs and cables according to manufacturer instructions.

- Safety Tips: Always follow the safety guidelines during installation to prevent injury.

Operation: Sectional overhead doors are operated using either manual pull chains or automatic motors. Ensure the motor is compatible with the door’s weight and size.

Maintenance:

- Lubricate moving parts regularly.

- Check door balance every six months to ensure it remains aligned.

- Inspect safety devices and sensors to ensure proper functioning.

- Preparation: Measure the opening and install tracks and mounting brackets before positioning the door.

- Step-by-Step Process:

- Install the side frames and connect the roller system.

- Attach the curtain to the roller and ensure it winds smoothly.

- Connect control panels for automated operation and program the door to desired opening and closing speeds.

- Operation: PVC high-speed doors are primarily operated by remote control or motion sensors, allowing for rapid opening and closing to maintain energy efficiency.

- Maintenance:

- Regularly inspect the PVC fabric for any signs of wear or damage.

- Lubricate the tracks and check sensors to ensure proper alignment.

- Clean the door surface to maintain transparency and avoid buildup of dust.

Installation Guide:

- Place the dock leveler within the loading dock pit.

- Ensure the hydraulic system is connected properly for automatic models.

- Attach safety chains and barriers as needed.

Operation: Dock levelers adjust to the height of trucks, creating a smooth bridge for forklifts and equipment. Operate by using the hydraulic controls or manual lift systems.

- Check the hydraulic fluid levels regularly.

- Inspect the platform for structural integrity and ensure that the lip extends properly.

- Clean and lubricate moving parts to ensure efficient operation.

- Mount the vehicle restraint system to the dock wall.

- Ensure the restraint arm is properly aligned with truck rear impact guards.

Operation: Vehicle restraints secure the truck in place during loading and unloading, preventing it from moving. Operate using manual or electric controls.

Maintenance:

- Inspect the restraint arms regularly for wear and tear.

- Check control systems and sensors to ensure they are functioning correctly.

- Clean the unit to prevent buildup of debris that could obstruct movement.

- Preparation: Ensure the ceiling structure is capable of supporting the fan’s weight.

- Step-by-Step Process:

- Secure the mounting bracket to the ceiling.

- Attach the fan blades and motor assembly.

- Connect the electrical wiring to the control panel.

Operation: Industrial ceiling fans are used to enhance air circulation in large facilities. Operate through wall-mounted or remote controls to adjust fan speed and direction.

Maintenance:

- Clean the fan blades regularly to prevent dust buildup.

- Inspect electrical connections for safety.

- Lubricate the motor and moving parts to ensure smooth operation.

- Always ensure the proper installation of safety features such as sensors and alarms.

- Follow local regulations and safety codes for installation and operation of all industrial equipment.

- Regularly schedule professional maintenance to extend the lifespan of your products and avoid downtime.

If you require additional assistance, our customer service team is here to help. Contact us for:

- Technical Support

- Product Manuals

- Professional Installation Services